System and method for recovering methyl nitrite through coal ethylene glycol carbonyl synthesis system

A coal-to-ethylene glycol and methyl nitrite technology, which is applied in the preparation of nitrite esters, chemical instruments and methods, and the preparation of organic compounds, can solve problems such as water resource pollution, improve economic benefits, and solve large consumption , The effect of reducing waste liquid pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

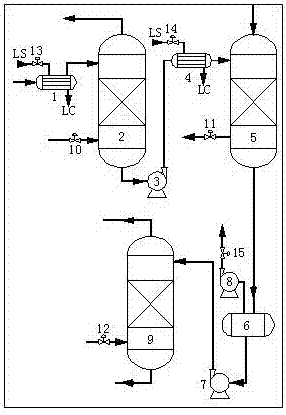

[0027] Coal-to-ethylene glycol carbonylation system to recover methyl nitrite, such as figure 1 As shown, it includes a front gas stripping unit, a nitric acid reduction unit, and a back gas stripping unit. The front gas stripping unit includes a front gas stripping tower liquid phase preheater 1, a front gas stripping tower 2 and a front gas stripping tower kettle liquid discharge Centrifugal pump 3, the upper end of the front stripping tower is provided with a gas phase outlet; the nitric acid reduction unit includes a nitric acid reduction liquid phase heater 4 and a nitric acid reduction reactor 5, and the upper end of the nitric acid reduction reactor is provided with a gas phase inlet; the rear stripping unit includes a flash The steaming tank 6, the liquid phase feed pump 7 of the rear stripping tower and the rear stripping tower 9; the liquid phase preheater of the front stripping tower is connected to the upper inlet of the front stripping tower through the liquid phase...

Embodiment 2

[0039] A method for recovering methyl nitrite from a coal-to-ethylene glycol carbonylation synthesis system. The method includes: the esterification reaction liquid in the ethylene glycol production process is sent to the liquid phase preheater of the front stripping tower through a pipeline, and preheated After reaching 60~80℃, the liquid enters the top of the front stripper through the upper inlet of the front stripper through the pipeline and is sprayed. The gas phase supplemented at the bottom of the front stripper is in reverse contact with the packing layer. The gas phase containing methyl nitrite at the top of the tower is returned to the synthesis system as a supplement; the contacted liquid enters the nitric acid reduction liquid phase heater through the centrifugal pump of the kettle liquid discharge of the front stripping tower, and is sent to the top of the nitric acid reduction reactor after heating , Make co-current contact with the gas phase supplemented at the to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com