A filling process of LNG skid-mounted filling station

A process and process technology, applied in the field of LNG filling stations, can solve the problems of poor thermal insulation, high evaporation loss rate, low reliability, etc., to reduce pre-cooling time, ensure production safety, and maximize flexibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

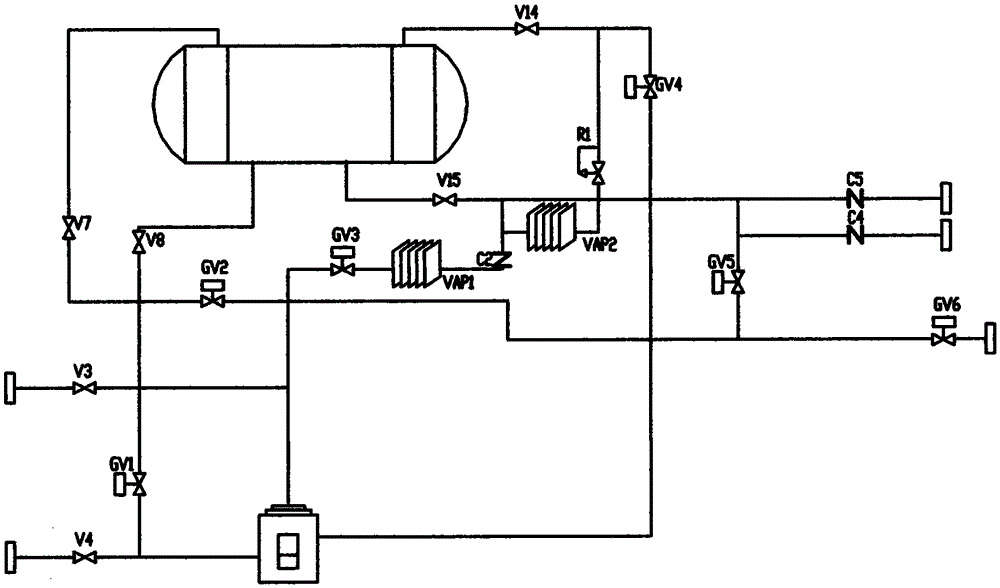

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

[0023] A filling process for an LNG skid-mounted filling station, including four processes, namely: unloading process, pressure regulation process, filling process, and pressure relief process. The four processes respectively adjust the system by means of an intelligent control panel. to unloading mode, pressure regulating mode, filling mode, and pressure unloading mode; the unloading process includes: (1) connecting the tank car and the Caohe unloading port with a hose, opening the V3 and V4 valves, and sending the unloading pipe through V1 and V2 The medium air is blown to the venting main pipe, and the intelligent control panel is adjusted to the unloading mode so that the pressure between the storage tank and the tank car is balanced (V14-GV4-pump-V4-liquid phase port-tank car liquid phase) and reaches the set pressure; (2) When the tank pressure drops to the set p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com