A continuous drying device for organic waste

A drying device and technology for organic waste, applied in drying, drying machine, drying gas arrangement and other directions, can solve the problems of low work efficiency, low work efficiency, impracticality, etc., and improve drying efficiency and air supply. The effect of avoiding and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

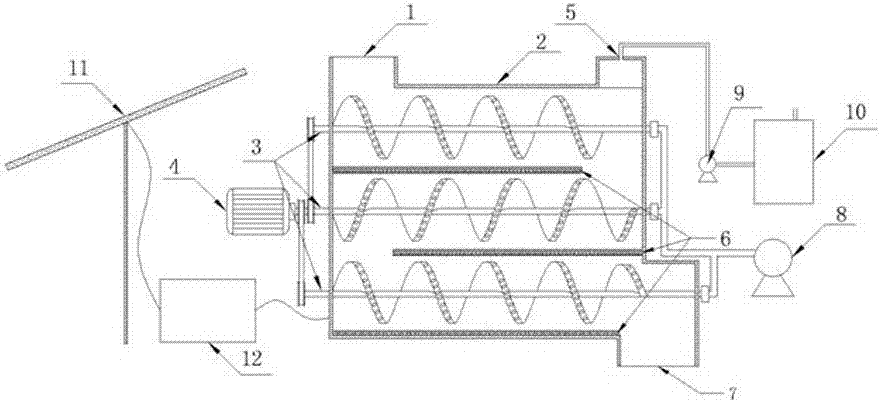

[0026] Such as figure 1 As shown, a continuous drying device for organic waste includes a drying chamber 2 provided with a feed inlet 1 and a discharge outlet 7 at the upper and lower diagonal positions, and also includes an odor treatment device, which is used for a mixer to push materials mobile stirring device,

[0027] The odor treatment device comprises a blower 9, an odor purification device 10 and an odor collection pipe 4, the exhaust port of the exhaust fan 10 is connected to the odor purification device 10, and the suction port is connected to the drying chamber by a pipeline. 2 The odor outlet 5 at the top, under the action of the exhaust fan, the dried odor enters the odor purification device 10 through the pipeline for treatment and discharge after reaching the standard;

[0028] The stirring device includes three spiral stirring shafts 3 horizontally arranged in the drying chamber 2 parallel to each other, a motor 4 arranged outside the drying chamber 2, a right...

Embodiment 2

[0035] The difference between this embodiment and embodiment 1 is that: the number of the spiral stirring shafts 3 is two, and the feed port 1 and the discharge port 7 are arranged on the same side of the upper and lower ends of the drying chamber 2 at this time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com