High-efficiency gas supply device for gas boiler

A gas-fired boiler, high-efficiency technology, applied to pump devices, components of pumping devices for elastic fluids, liquid fuel engines, etc., can solve the problems of gas-fired boilers lack of oxygen, time-consuming disassembly and assembly of fans, and easy adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in further detail below in conjunction with the accompanying drawings.

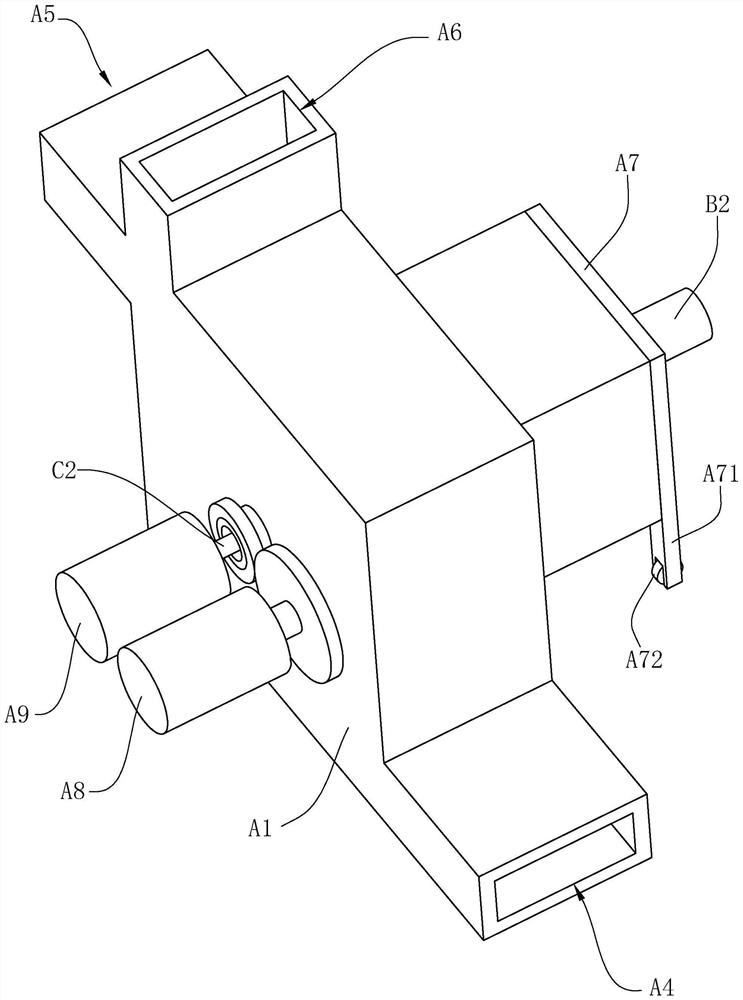

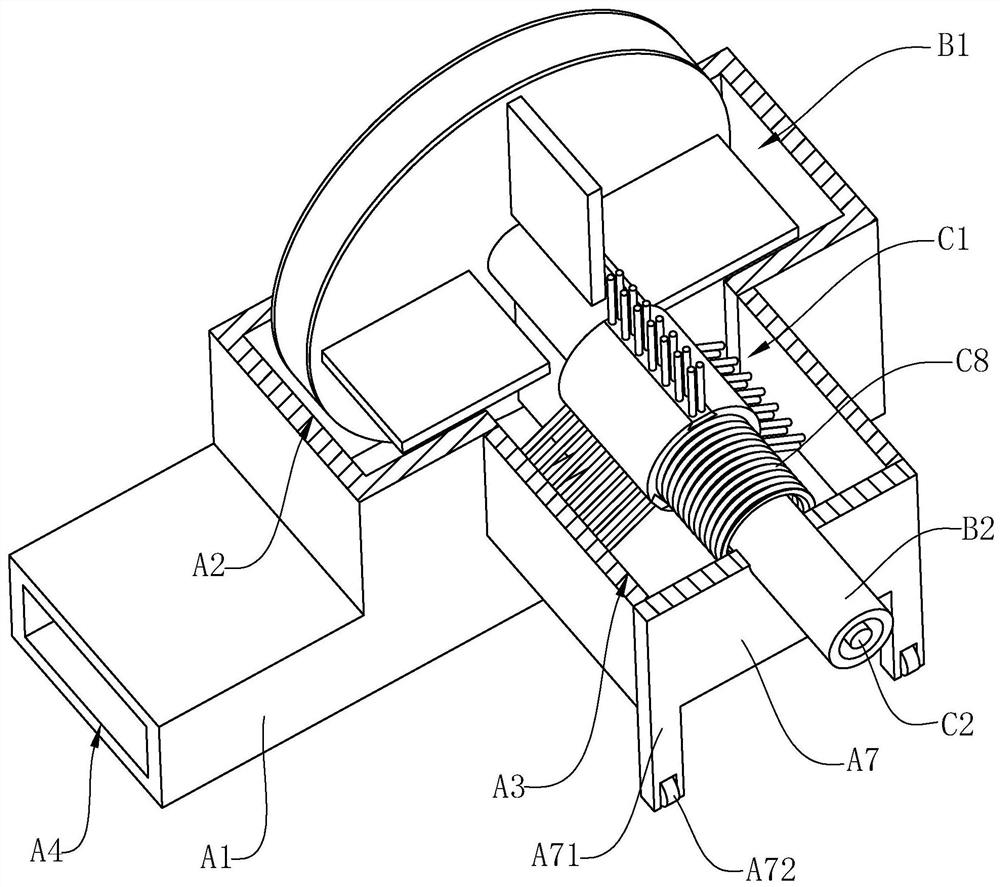

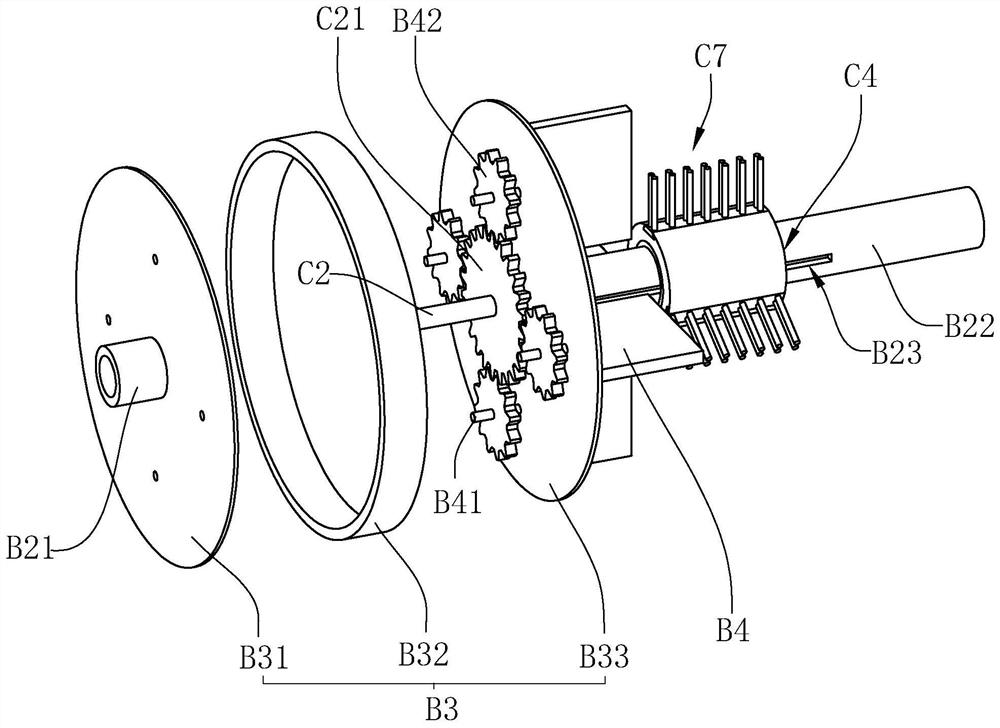

[0047] Such asfigure 1 with figure 2 As shown, a gas-fired boiler high-efficiency gas supply device includes a casing A1, an acceleration component B1 and a cleaning component C1. An acceleration chamber A2 and a storage cavity A3 are arranged in the casing A1. The acceleration chamber A2 communicates with the storage cavity A3, and the acceleration component B1 is rotated and installed in the acceleration chamber A2, and the cleaning component C1 is movably arranged in the acceleration chamber A2 and the storage chamber A3, and the housing A1 is also provided with an air inlet A4, an air outlet A5 and The second air outlet A6, wherein the first air outlet A5 and the second air outlet A6 are respectively provided with valves;

[0048] When the device is in the normal air supply state, the first air outlet A5 is opened and the second air outlet A6 is closed,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com