Pre-assembling clamp, application thereof, welding method and welded piece

A welding method and fixture technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of complicated operation steps and long time-consuming, and achieve the effect of simple operation steps, short time-consuming and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

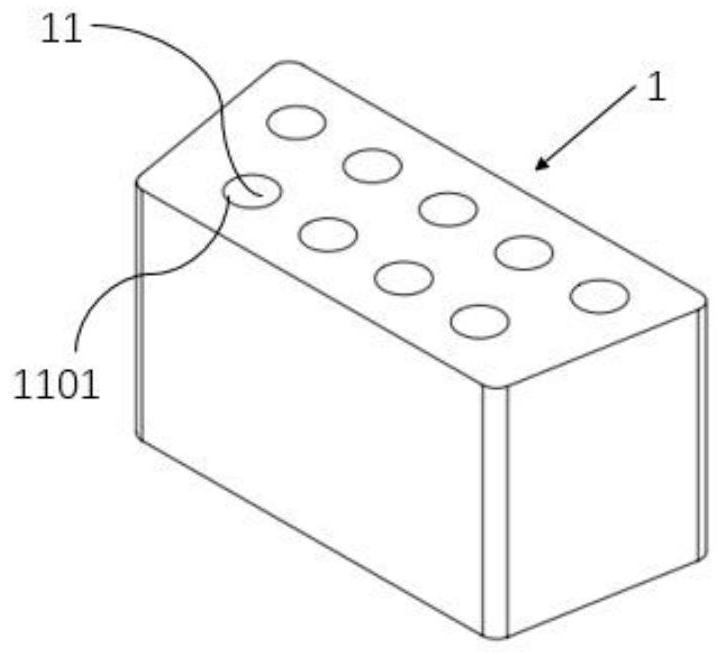

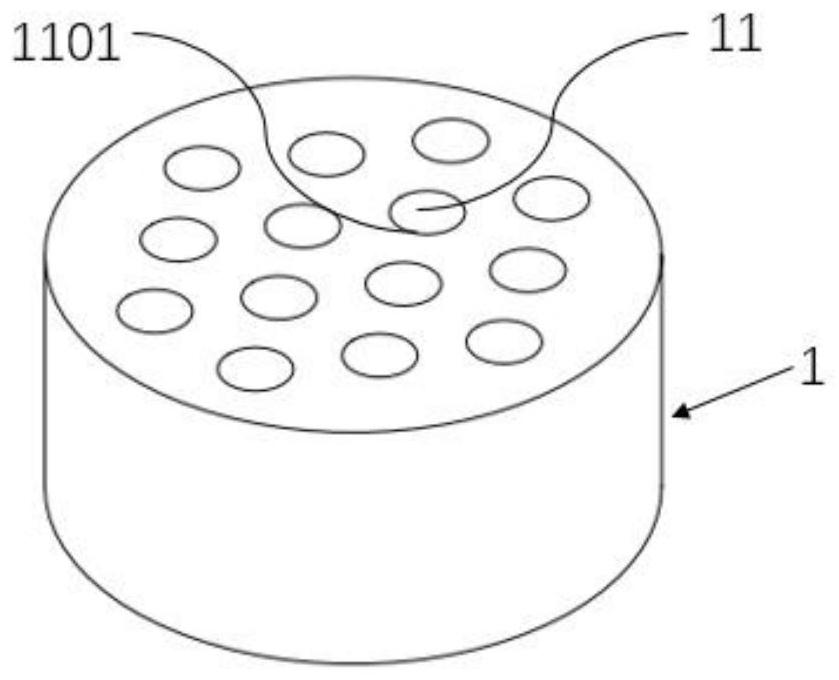

[0042] In order to solve the problem of cumbersome operation and long time-consuming when the heat-shrinkable tube in the prior art is used to weld the cable interface and cables of several pins, the present invention provides a pre-installed fixture 1 for cables and cable interfaces ,Such as figure 1 and figure 2 As shown, there are several passages 11 passing through the pre-installation fixture 1 , and the two ends of the passages 11 form two mouths 1101 and 1102 with the surface of the pre-installation fixture 1 respectively. Wherein, the two openings 1101 and 1102 of the channel 11 are respectively used for inserting cables and inserting corresponding pins of the cable interface.

[0043] The pre-installation jig 1 provided in this embodiment uses the partitions naturally formed between the channels 11 by the pre-installation jig 1 to replace the heat shrinkable tubes in the prior art, so as to realize the insulation and isolation of each welded part. When the pre-inst...

Embodiment 2

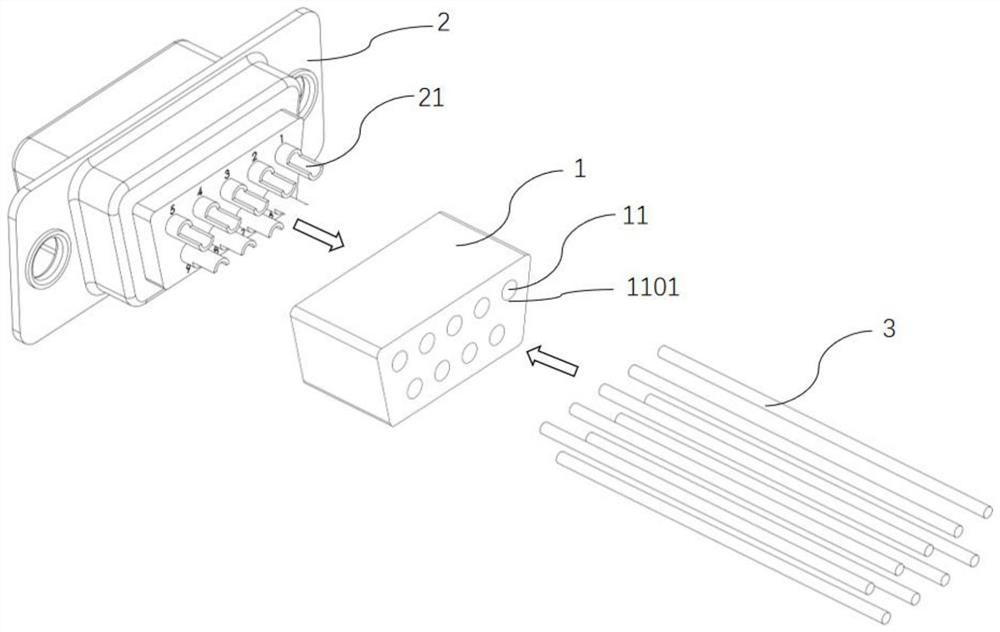

[0056] The welding method of the cable and the cable interface in the prior art has the technical defects of cumbersome operation steps and long time consumption. In view of the above technical defects, the present invention provides a welding method of the cable and the cable interface. The pre-installed fixture 1 provided in Embodiment 1; the cable includes several core wires 3; the cable interface 2 includes several pins 21, wherein the pins 21 are used for welding with the core wires 3; the number of core wires 3, pins The quantity of 21, the quantity of channel 11 are all equal; The welding method comprises the following steps:

[0057] 1. The pre-installation step is to set all the core wires 3 and all the pins in the pre-installation fixture 1, so that each pin 21 is arranged in a channel 11 opposite to a core wire 3; wherein, before the pre-installation step, The relative positions of all core wires 3, all pins 21 and pre-installed fixture 1 are as follows: image 3 s...

Embodiment 3

[0074] In order to provide a cable welding piece whose welding part is not easily damaged, the present invention provides a welding piece, such as Figure 5 As shown, it includes a cable interface 2, several core wires 3 and a pre-installed clamp 1;

[0075] The cable interface 2 includes several pins 21;

[0076] The pre-installation fixture 1 includes several passages 11 passing through the pre-installation fixture 1, and the two ends of the passage 11 respectively form two mouths 1101 and 1102 with the surface of the pre-installation fixture 1;

[0077] The number of core wires 3 is equal to the number of pins 21 and the number of channels 11;

[0078] Inside each channel 11, a core wire 3 and a pin 21 are fixed by welding.

[0079] The structure of the cable weldment provided by Example 3 is simple, and the insulation and isolation between multiple welding parts (the welding part of the core wire 3 and the pin 21) is realized by using the pre-installation fixture 1. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com