Synthesis method and equipment of alkyl nitrite

A technology of alkyl nitrite and synthesis method, applied in the directions of nitrite preparation, organic chemistry, etc., can solve problems such as few research reports

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

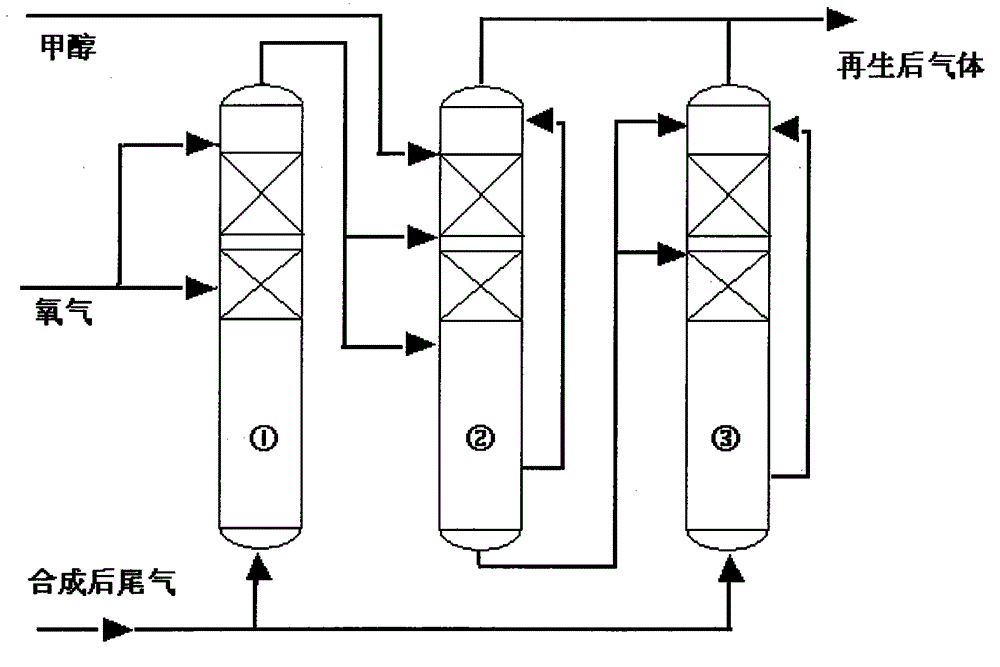

Image

Examples

Embodiment 1

[0052]

[0053]

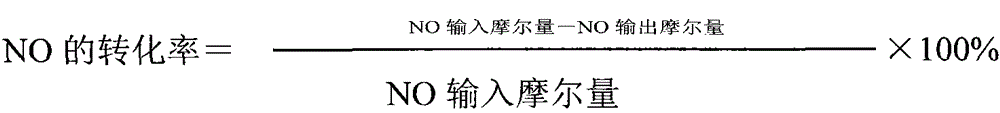

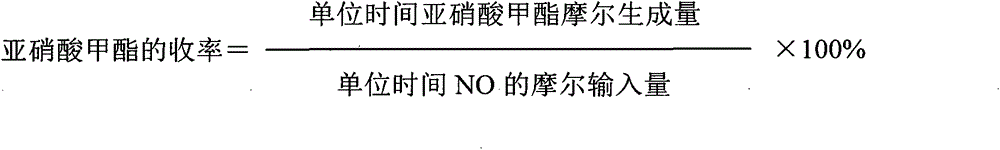

[0054] Table 1: Effect of esterification tower temperature on NO conversion rate and methyl nitrite yield

[0055]

Embodiment 2

[0057] Other conditions were the same as in Example 1. The reaction temperature of the esterification tower was 80° C., and the pressure in the esterification tower was controlled to prepare the ester. The influence of the pressure on the conversion rate of NO and the yield of methyl nitrite is shown in Table 2.

[0058] Table 2: Effect of esterification tower pressure on NO conversion rate and methyl nitrite yield

[0059]

Embodiment 3

[0061] Other conditions are the same as in Example 1, the reaction temperature of the esterification tower is 80°C, the input amount of O2 in the fully mixed tower, such as the system NO intake amount is constant, and the ratio of different NO and O2 is different for the conversion rate of NO and methyl nitrite The impact of the yield is shown in Table 3.

[0062] Table 3 The effect of the ratio of NO and O2 on the conversion rate of NO and the yield of methyl nitrite

[0063]

[0064]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com