Preparation method of C1-C4 alkyl nitrite and reaction equipment implementing same

A technology of C1-C4 and nitrous acid, applied in the direction of preparation of nitrite ester, chemical method for reacting liquid and gas medium, chemical instrument and method, etc., can solve problems such as inability to effectively control the oxidation composition of nitrogen oxides, and achieve The effect of short reaction time, simple reaction equipment, and few by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

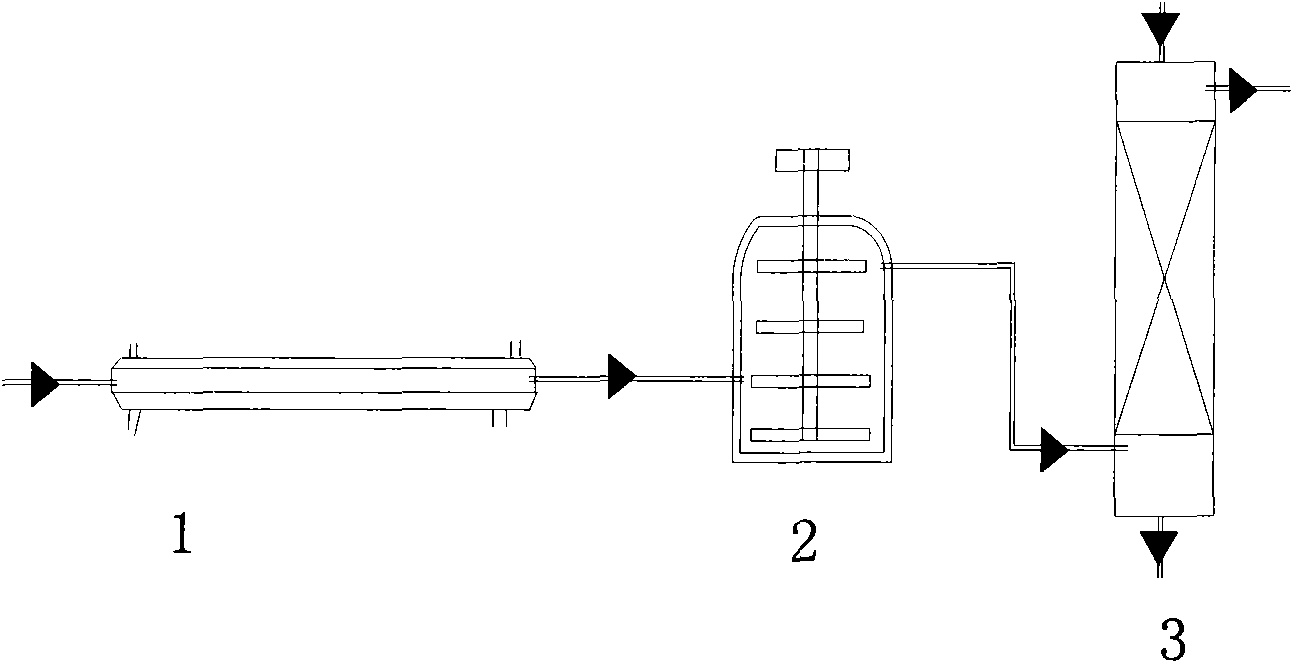

[0055] The present invention is carried out in plug-flow isothermal reactors, fully mixed isothermal reactors and packed towers. The plug-flow isothermal reactor is made of quartz glass with an inner diameter of 25mm and a tube length of 250mm; the fully mixed isothermal reaction also uses quartz glass with an inner diameter of 150mm and a height of 250mm, and a stirring paddle is added to accelerate the full mixing (paddle or anchor stirring) device, about 250 to 300 rpm); the esterification packed tower is a stainless steel pipe with an inner diameter of 25mm and a pipe length of 1000mm, filled with different types of fillers. There is a casing outside the three devices, and the constant temperature water of different temperatures provided by the constant temperature water bath is respectively introduced into the casing. Experimental conditions: the pressures of plug flow reactor, fully mixed reactor and esterification packed tower are respectively: 0.2Mpa, 0.1Mpa and 0.1Mpa...

Embodiment 2

[0059] Embodiment 2: other conditions are identical with embodiment 1, be porcelain Raschig ring (Dg25) in the esterification packing tower, and temperature is 100 ℃, changes O 2 The amount of feed, thus changing the NO and O 2 Ratio of feed to prepare methyl nitrite.

[0060] Table 2: NO and O 2 Comparison of the yield of methyl nitrite under the feed ratio

[0061]

[0062] NO and O 2 Feed ratio Methyl nitrite yield (%)

[0063]

[0064] 4:1 99.38

[0065] 4.5:1 99.39

[0066] 5:1 99.39

[0067]

Embodiment 3

[0068] Embodiment 3: Other conditions are the same as in Implementation 1, the esterification packed tower is made of porcelain Raschig rings (Dg25), the temperature is 100° C., and the nitrogen feed flow rate is changed to prepare methyl nitrite.

[0069] Table 3: Comparison of methyl nitrite yields under different nitrogen feed rates

[0070]

[0071] Feed amount of nitrogen (ml / min) Methyl nitrite yield (%)

[0072]

[0073] 20 99.66

[0074] 60 98.65

[0075] 100 97.50

[0076] 120 97.36

[0077]

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com