Synthesizing device and process for alkyl nitrite

A technology for an alkyl nitrite and a synthesis device, which is applied in the chemical field to achieve the effects of good economy, reduced equipment investment and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

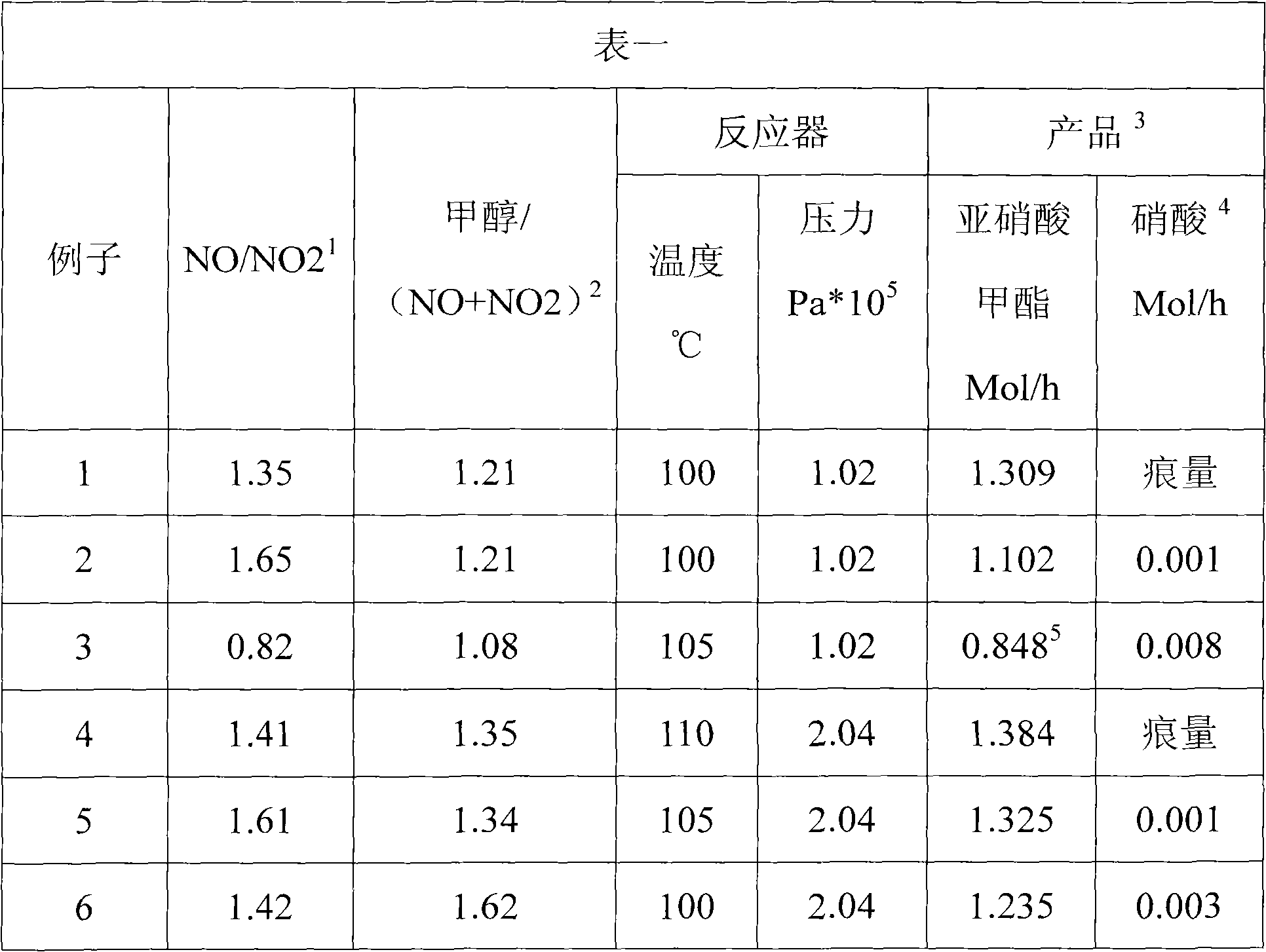

Examples

Embodiment Construction

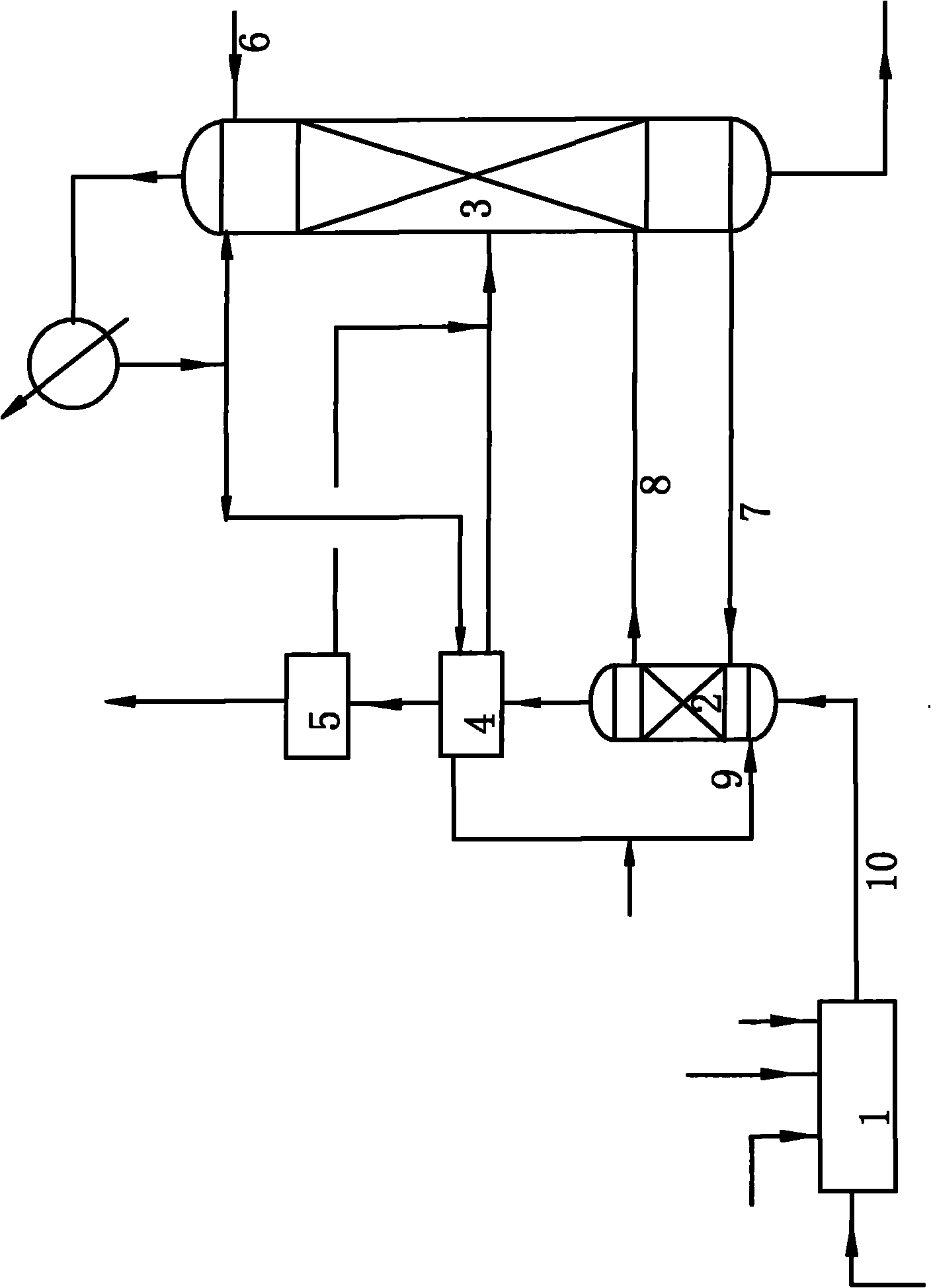

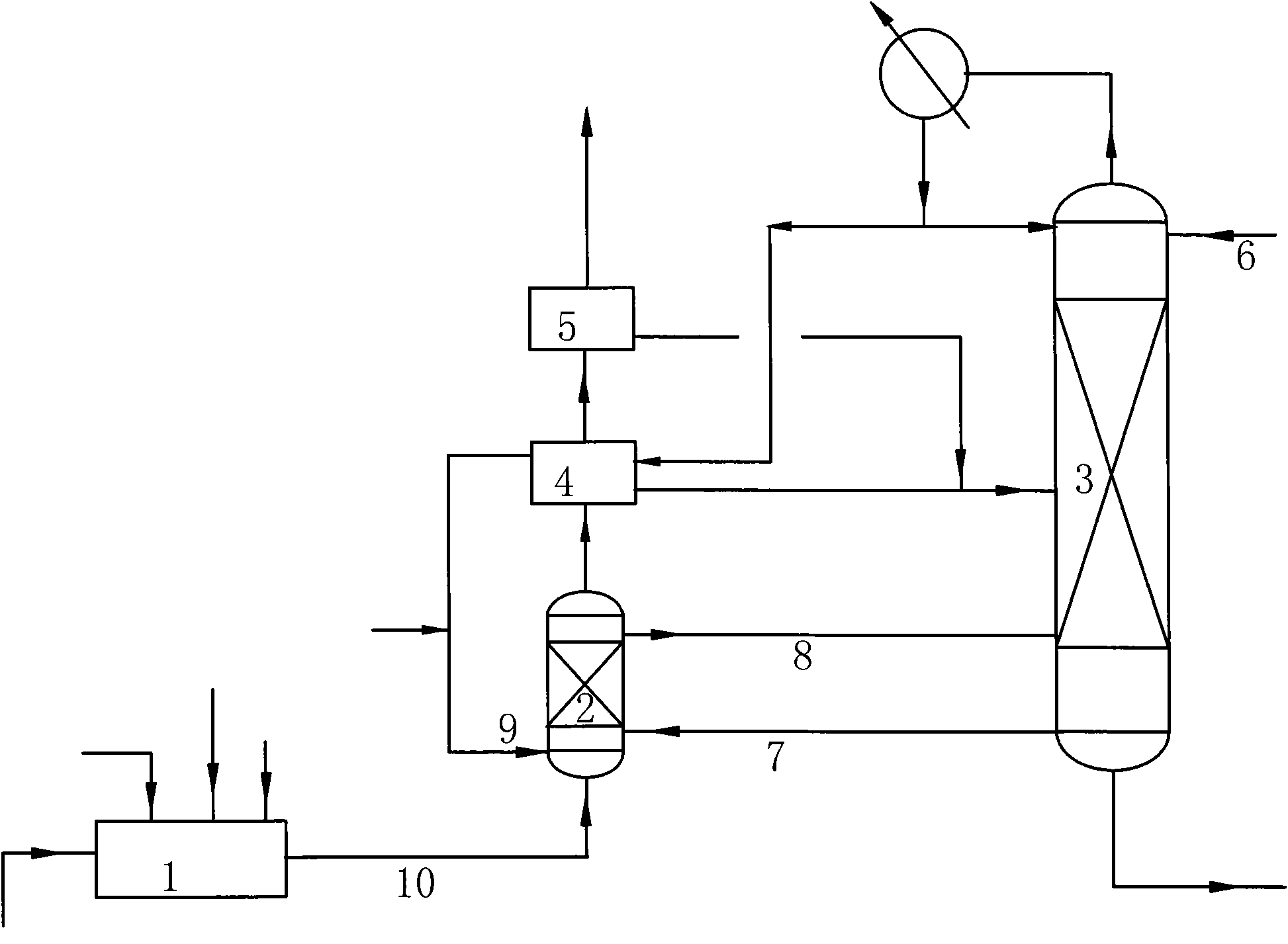

[0031]As shown in the figure; use a 304 stainless steel tubular reactor as the oxidizer 1, use a 304 stainless steel fixed bed tubular reactor as the nitrite reactor 2, and use a 304 stainless steel Raschig ring packing The installed rectification column 3 uses a 304 stainless steel shell-and-tube heat exchanger as the vaporizer 4, and a 304 stainless steel shell-and-tube heat exchanger as the heat exchanger 5 (where circulating water or frozen brine is used as the heat exchange medium) , As the alkyl alcohol, methanol is used. ① The oxidizer 1 and the heat exchanger 4 are respectively connected to the inlet of the tube side of the reactor 2 through at least one pipeline, so as to send nitrogen oxides and alkyl alcohol gas to the tube side of the reactor for reaction. ②The lower part of the rectification tower 3 is connected to the shell-side inlet and outlet of the reactor 2 through two pipelines, thereby realizing the removal of the tube-side reaction heat through the heatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com