Process device for producing methyl nitrite

A technology of methyl nitrite and process equipment, applied in the field of process equipment for the production of methyl nitrite, can solve the problems of rising production process equipment costs, waste of process soft water, high equipment costs, etc., and achieve the effect of saving equipment and production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

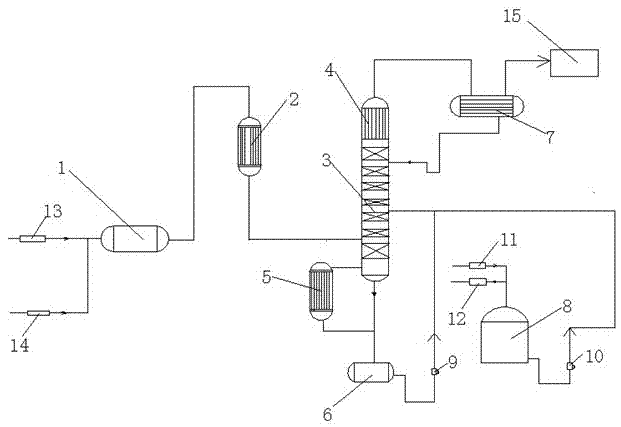

[0008] Below in conjunction with accompanying drawing, describe in further detail:

[0009] Such as figure 1 As shown, the device comprises a nitrogen dioxide pre-reactor 1, a nitrogen dioxide preheater 2, a reactive distillation tower 3, a reboiler 5, a methanol recovery buffer tank 6 and an acid water tank 8, and the reactive distillation tower 3 top Built-in condenser 4, nitrogen dioxide prereactor 1, nitrogen dioxide preheater 2, reactive distillation column 3, reboiler 4 and methanol recovery buffer tank 5 are connected in sequence, and the input of nitrogen dioxide prereactor 1 The ends are respectively connected with the NO circulating air pipe 13 and the oxygen pipeline of the NO circulating gas from the nitrogen compressor in the carbonylation reaction 15 process, and the oxygen pipeline is provided with an air separation device 14, and the outside air is separated into pure oxygen through the air separation device 14, and then The two ends of the cooler 7 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com