Continuous feeding device of nitrite gas

A technology of nitrite ester and supply device, applied in the direction of nitrite ester preparation, organic chemistry, etc., which can solve the problems of inaccurate gas mixture ratio and difficult test catalyst life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

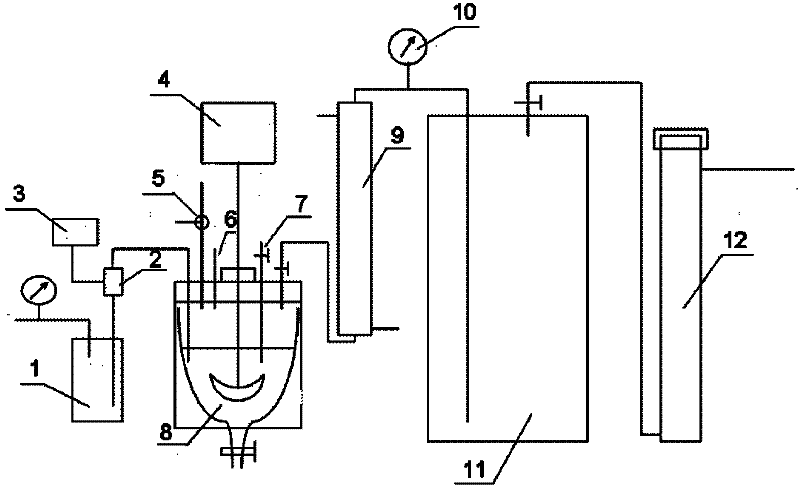

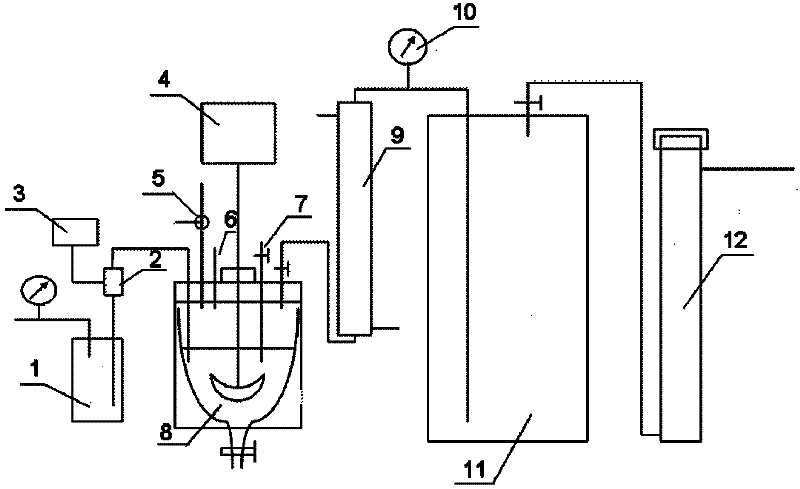

[0023] Put the mixed solution of 140g of sodium nitrite and 100mL of methanol into a polytetrafluoroethylene-lined reaction kettle, then seal the reaction kettle well, and circulate nitrogen for three times. Open the N to the concentrated sulfuric acid storage tank 2 Air flow, adjust the outlet pressure to 0.2Mpa, set the switching frequency of the solenoid valve on the computer, so that the concentrated sulfuric acid in the storage tank is slowly added to the reactor, and reacts with sodium nitrite and methanol to generate methyl nitrite gas. After the methyl nitrite gas generated by the reaction passes through the reflux condenser at -5°C, a small amount of methanol and water vapor are frozen back to the reactor, and the purified gas enters the methyl nitrite gas storage tank, and the methyl nitrite in the storage tank The gas is then dried in a drying tower to further remove residual water vapor, and then sent to the catalyst evaluation device through a pressure-stabilizing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com