Equipment for rapidly and continuously manufacturing droplet microspheres and application thereof

A droplet and equipment technology, applied in the field of droplet microsphere preparation, can solve problems such as difficulty, inability to meet, and large mutual influence, and achieve the effect of promoting production speed, fast and efficient production, and speeding up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

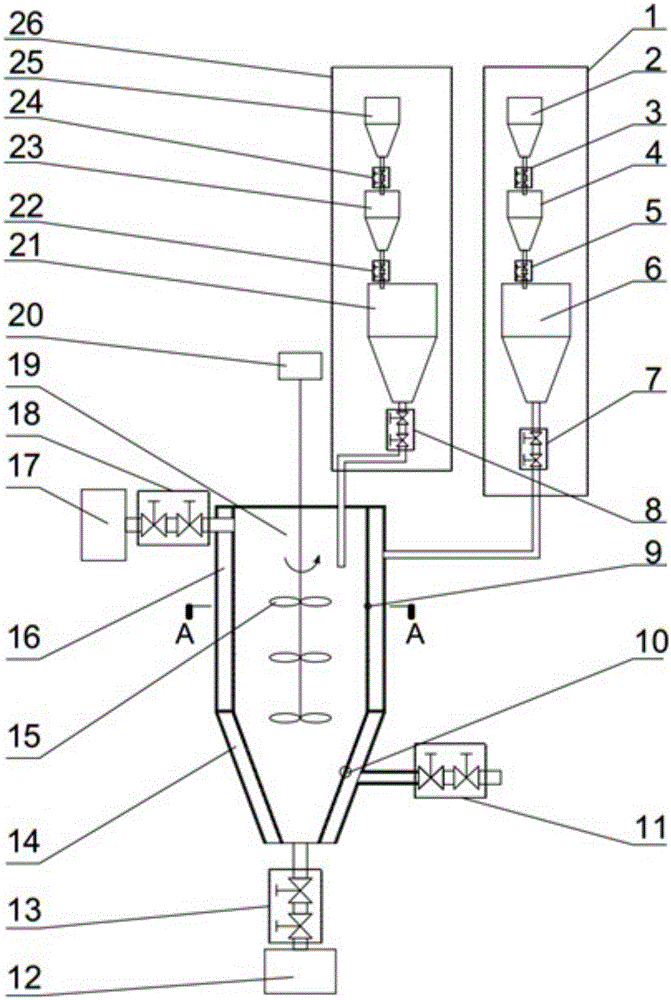

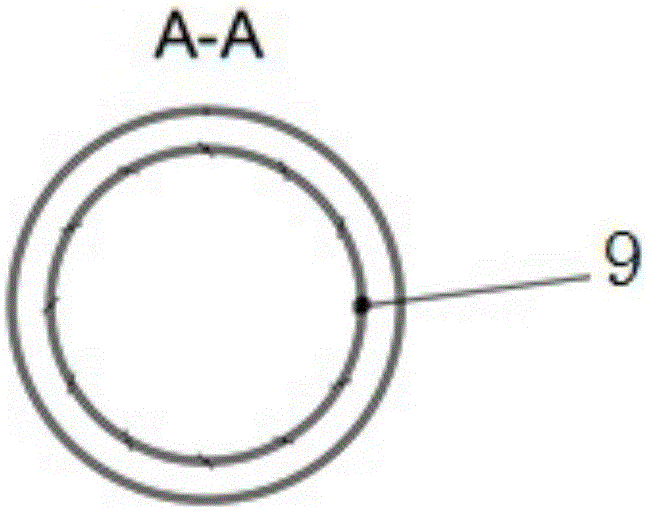

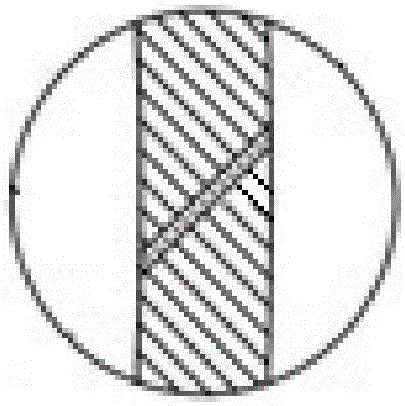

[0033] This embodiment provides a device for rapidly and continuously preparing droplet microspheres, such as figure 1 As shown, the equipment includes a dispersed phase feeding device 1, a continuous phase feeding device 26, a continuous phase pressure tank 19 and a rotary agitation device. The top of the continuous phase pressure tank 19 is in communication with the continuous phase feeding device 26, and the continuous phase pressure tank The bottom of 19 is provided with a discharge port, and the side wall of the continuous phase pressure tank 19 is provided with a discharge port, dispersed phase inlet hole 9 and air distribution hole 10 from top to bottom, the dispersed phase feeding device 1 and the dispersed phase The inlet hole 9 is connected, and the rotary stirring device is arranged in the continuous phase pressure tank 19.

[0034] Among them, the dispersed phase feeding device 1 includes a dispersed phase atmospheric storage tank 2, a dispersed phase buffer storage ta...

Embodiment 2

[0044] This embodiment provides a device for rapidly and continuously preparing droplet microspheres. The structure is as described in Embodiment 1, and the difference is that the continuous phase pressure tank 19 includes an upper cylindrical tank body and a lower truncated cone-shaped tank. The dispersed phase inlet hole 9 is located on the side wall of the cylindrical tank, and the air distribution hole 10 is located on the side wall of the truncated cone-shaped tank.

Embodiment 3

[0046] A. The specific operation steps of disperse phase continuous feeding are as follows:

[0047] (1) Add the dispersed phase to the dispersed phase normal pressure storage tank 2, close the double valve 5 between the dispersed phase buffer storage tank 4 and the dispersed phase high pressure storage tank 6, and open the dispersed phase normal pressure storage tank 2 The double valve 3 between and the dispersed phase buffer storage tank 4, the dispersed phase flows from the dispersed phase atmospheric storage tank 2 into the dispersed phase buffer storage tank 4;

[0048] (2) When the dispersed phase in step (1) enters the 3 / 4 position in the dispersed phase buffer storage tank 4, close the double valve between the dispersed phase atmospheric storage tank 2 and the dispersed phase buffer storage tank 4 3. Press into the dispersed phase buffer storage tank 4;

[0049] (3) After the pressure in the dispersed phase buffer storage tank 4 is the same as the pressure in the dispersed p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com