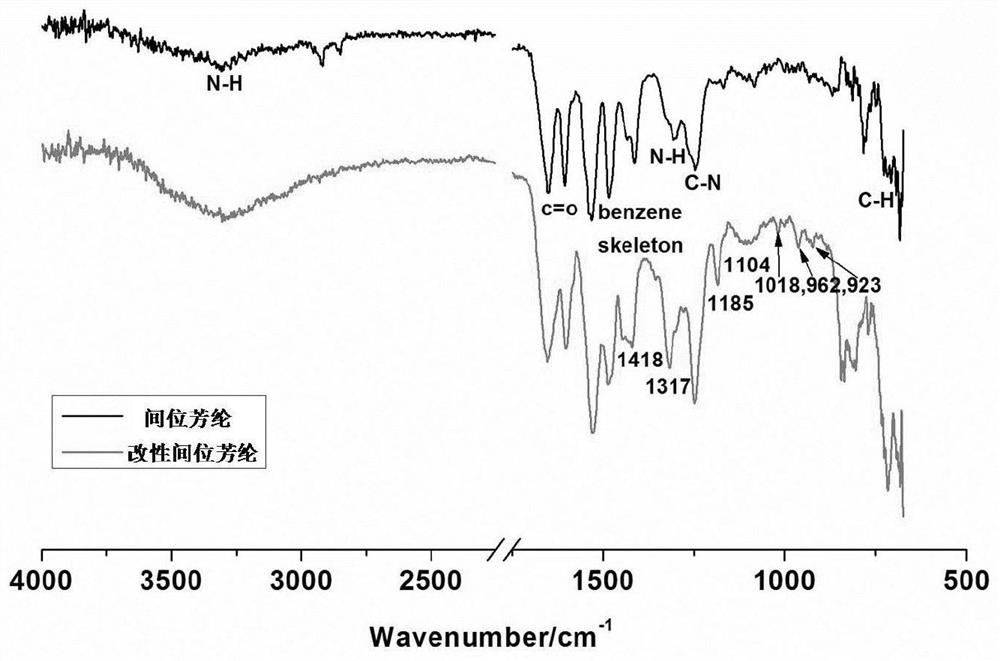

Method and device for preparing modified meta-aramid fiber through continuous polymerization-dry-wet spinning

A dry-wet spinning, aramid fiber technology, applied in the direction of single-component synthetic polymer rayon, rayon manufacturing, fiber chemical characteristics, etc., can solve the problem of low local polymerization degree, spinneret clogging, and many side reactions and other problems, to achieve stable and controllable intrinsic viscosity, to prevent the formation of by-products, and to avoid the effects of wool or broken filaments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

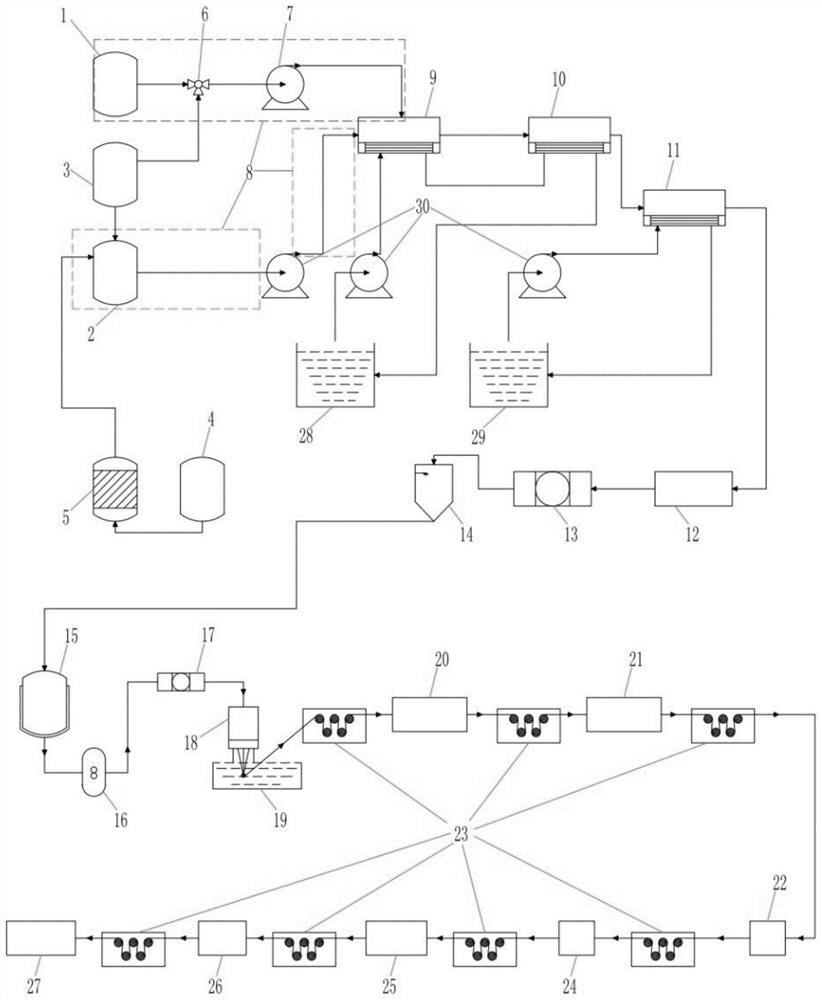

[0065] The embodiments of the present invention are all carried out in a device for preparing modified meta-aramid fibers by continuous polymerization-dry-wet spinning, refer to figure 1 , the device includes the following systems:

[0066]① Raw material storage device: including isophthaloyl chloride raw material storage tank 1, m-phenylenediamine and copolymerized diamine monomer raw material storage tank 2, solvent storage tank 3, solvent raw material storage tank containing co-solvent 4, and dehydration device 5; The above-mentioned raw material storage device, the solvent raw material storage tank 4 containing cosolvent is connected to the dehydration device 5, and the dehydration device 5 and the solvent storage tank 3 are connected to the m-phenylenediamine and copolymerized diamine monomer raw material storage tank 2, isophthaloyl dichloride The raw material storage tank 1 is connected to the advection pump 7 and the solvent storage tank 3 through the three-way valve ...

Embodiment 2

[0080] The reaction device is the same as in Example 1, the spinneret hole diameter in Example 1 is adjusted to 0.1mm, the air layer is adjusted to 20mm, and the speed of the first drafting roller is adjusted to 3.0 times the speed of the spinning stock solution; the first coagulation bath The concentration of DMAC was adjusted to 35%, the temperature was adjusted to 40°C, the concentration of DMAC in the second coagulation bath was adjusted to 25%, the temperature was adjusted to 45°C, and the plasticizing draw ratio was adjusted to 2.5; other processes and process parameters were the same as in Example 1.

Embodiment 3

[0082] The reaction device is the same as in Example 1, the height of the air layer in Example 1 is adjusted to 10mm, the speed of the first drafting roller is adjusted to 2.0 times the speed of the spinning stock solution, the temperature of the first coagulation bath is adjusted to 35 ° C, the second The coagulation bath was adjusted to 45° C., and the plasticizing stretch ratio was adjusted to 2.8; other processes and process parameters were the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com