Non-noble metal catalyst film electrode endurance test method

A test method, non-precious metal technology, applied in the direction of circuits, fuel cells, electrical components, etc., can solve the problems of membrane electrode performance degradation, cathode oxygen transmission resistance increase, no attenuation test method, etc., to avoid water flooding, test data Authentic and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

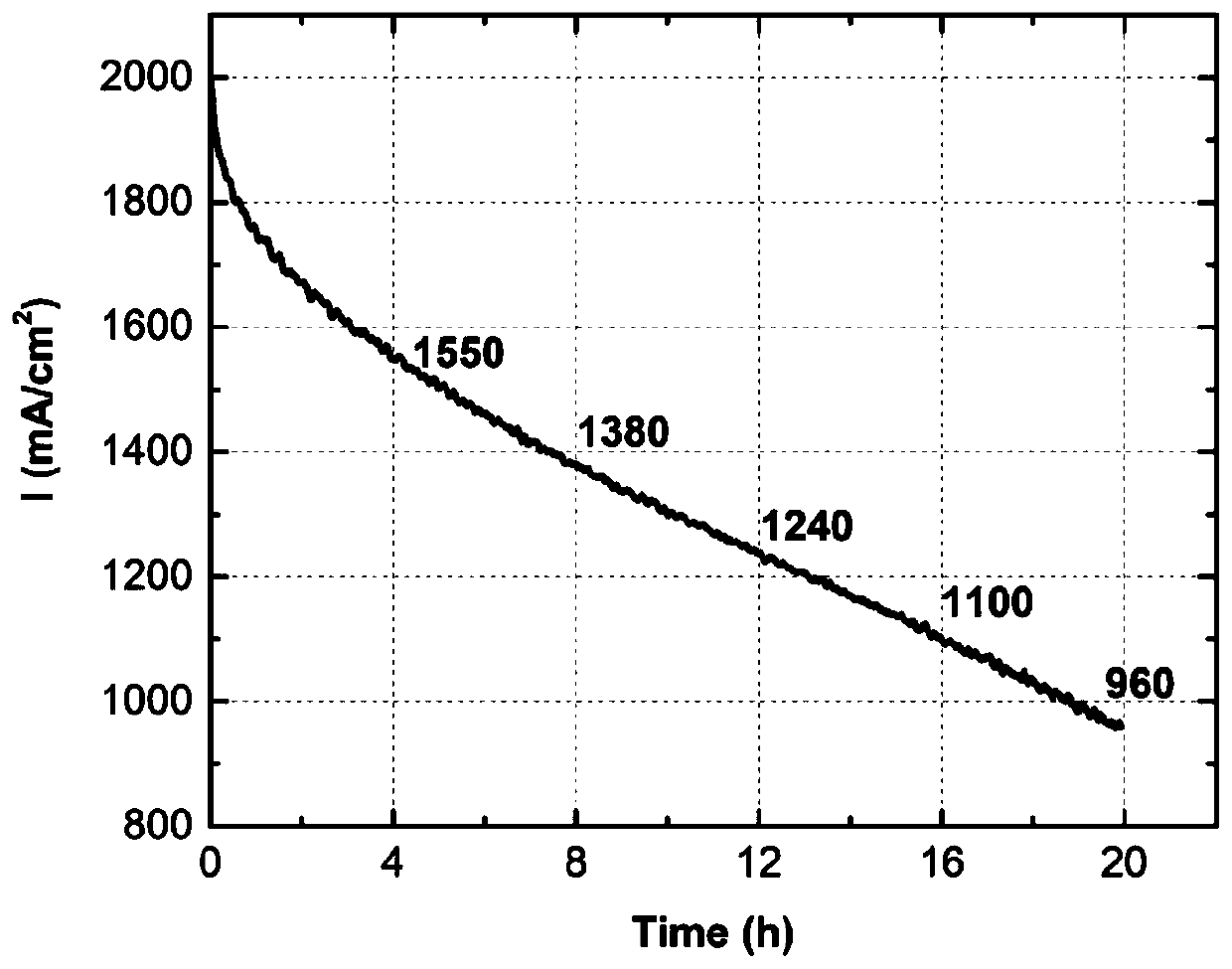

[0045] This embodiment provides a non-precious metal catalyst (Fe / N / C catalyst) membrane electrode durability test method, including the following steps:

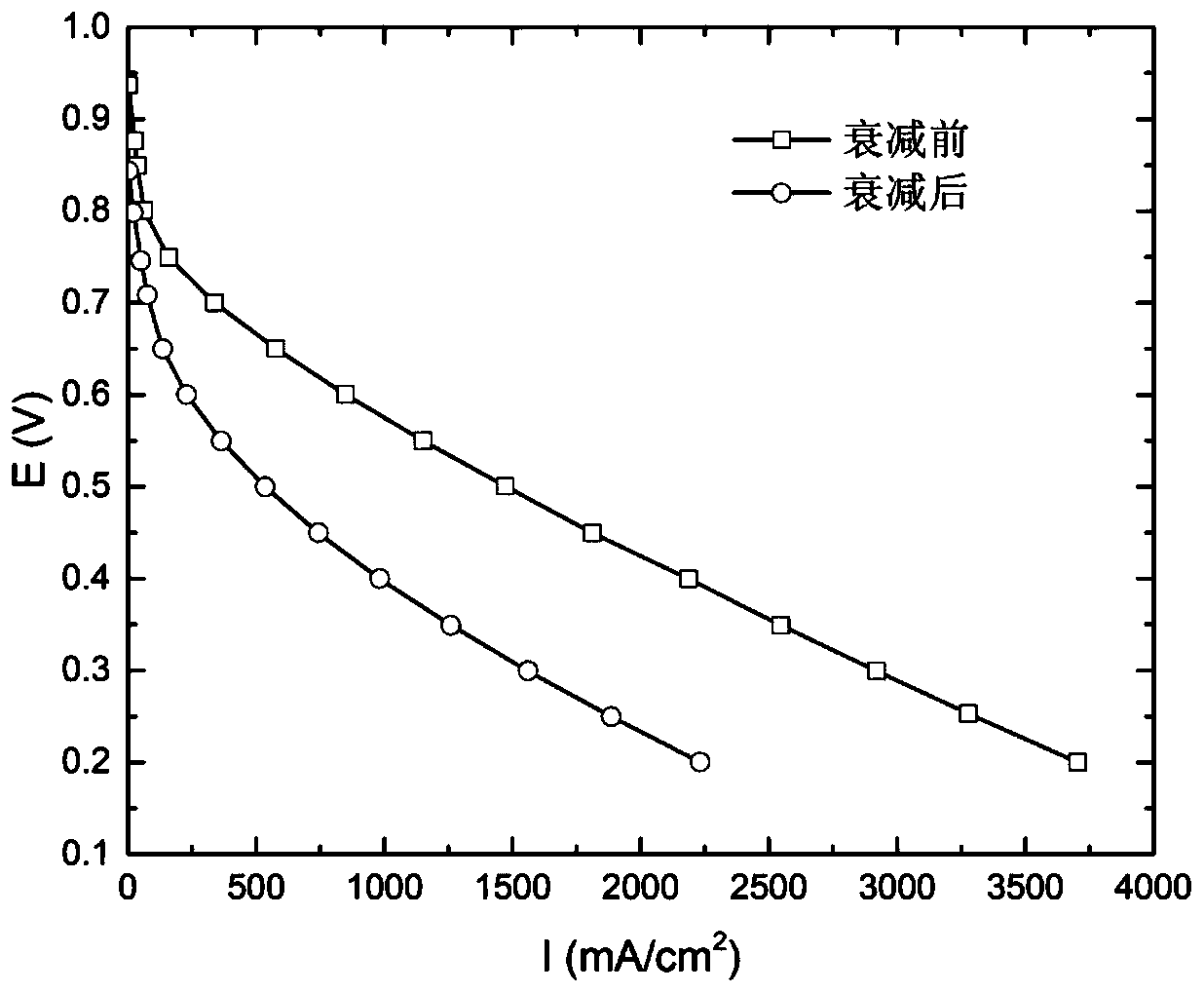

[0046] 1) Test the polarization curve of membrane electrode before decay with electrochemical workstation

[0047] The anode of the membrane electrode is fed with hydrogen, and the cathode is fed with pure oxygen. The relative humidity used was 100%, the back pressure used was 150 kPa, and the temperature used was 80°C. The voltage range is 0.2~0.95V, and the discharge current is tested and recorded every 0.05V for 60s.

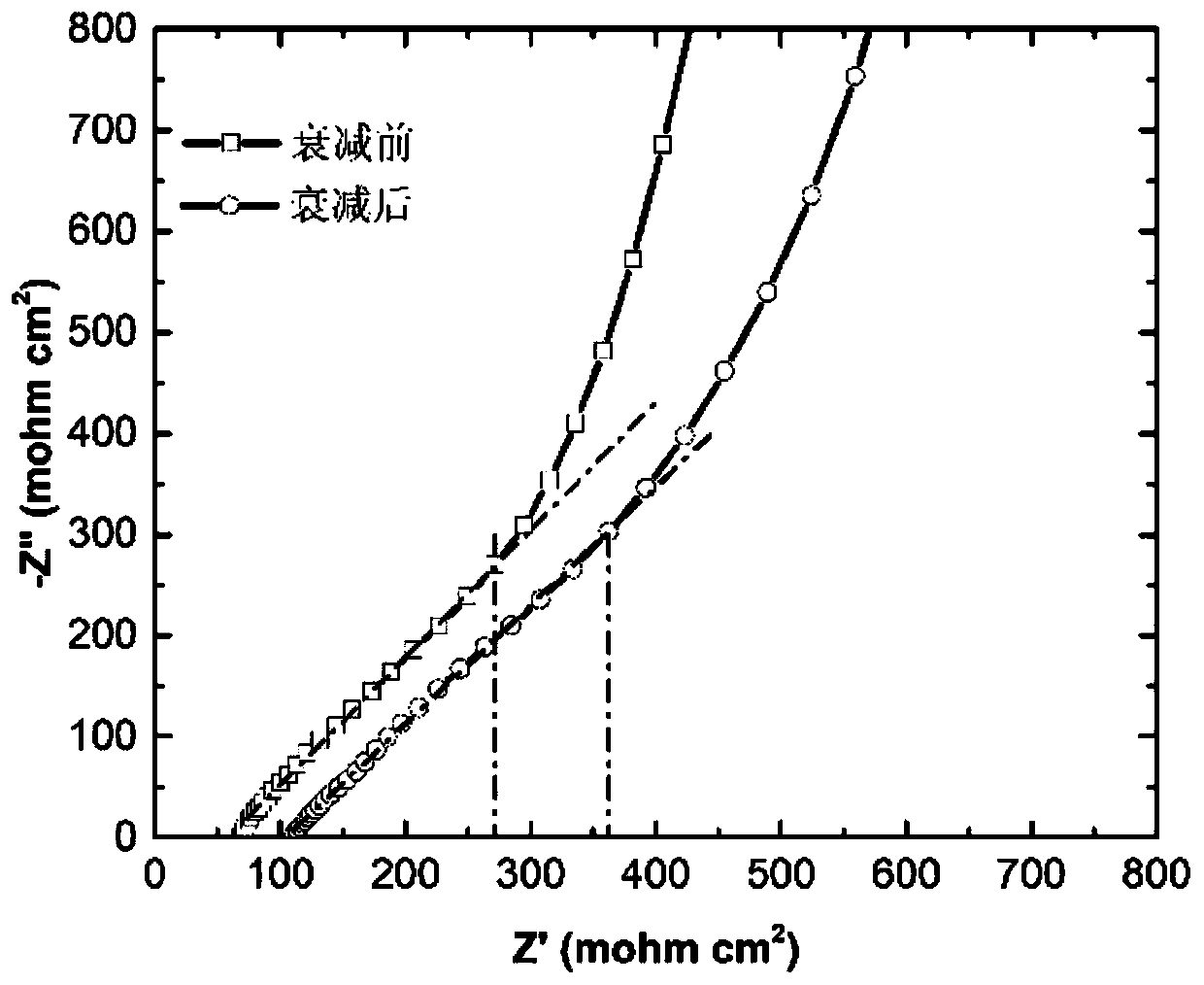

[0048] 2) Test the membrane electrode ohmic impedance and catalytic layer proton conduction impedance before attenuation with an electrochemical workstation

[0049] The anode of the membrane electrode was fed with hydrogen gas, and the cathode was fed with nitrogen gas. The relative humidity used was 100%, the back pressure used was 150 kPa, and the temperature used was 80°C. The used frequency range i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com