Novel method for preparing core-shell structure catalyst

A core-shell structure and catalyst technology, which is applied in the field of novel preparation of core-shell structure catalysts, can solve the problems of insignificant improvement in preparation efficiency, complicated relative reaction methods, etc., so as to save preparation raw materials, reduce reduction time, and improve quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

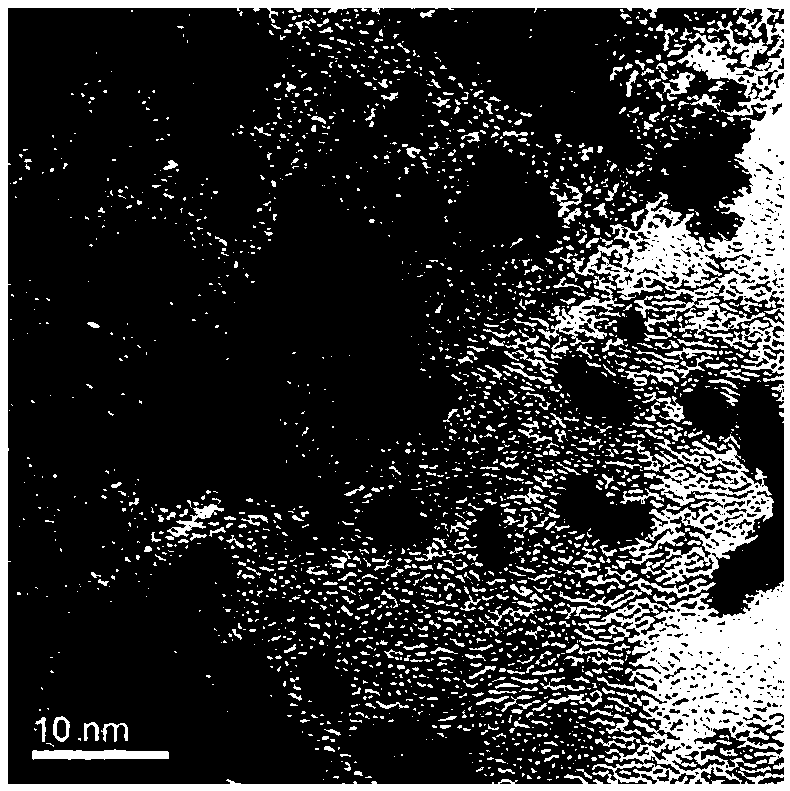

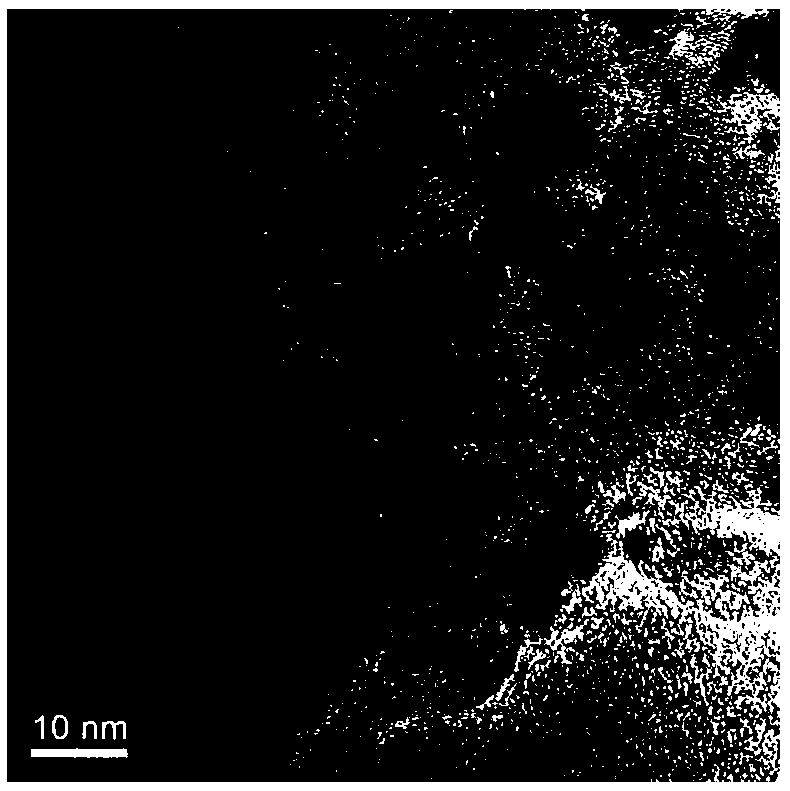

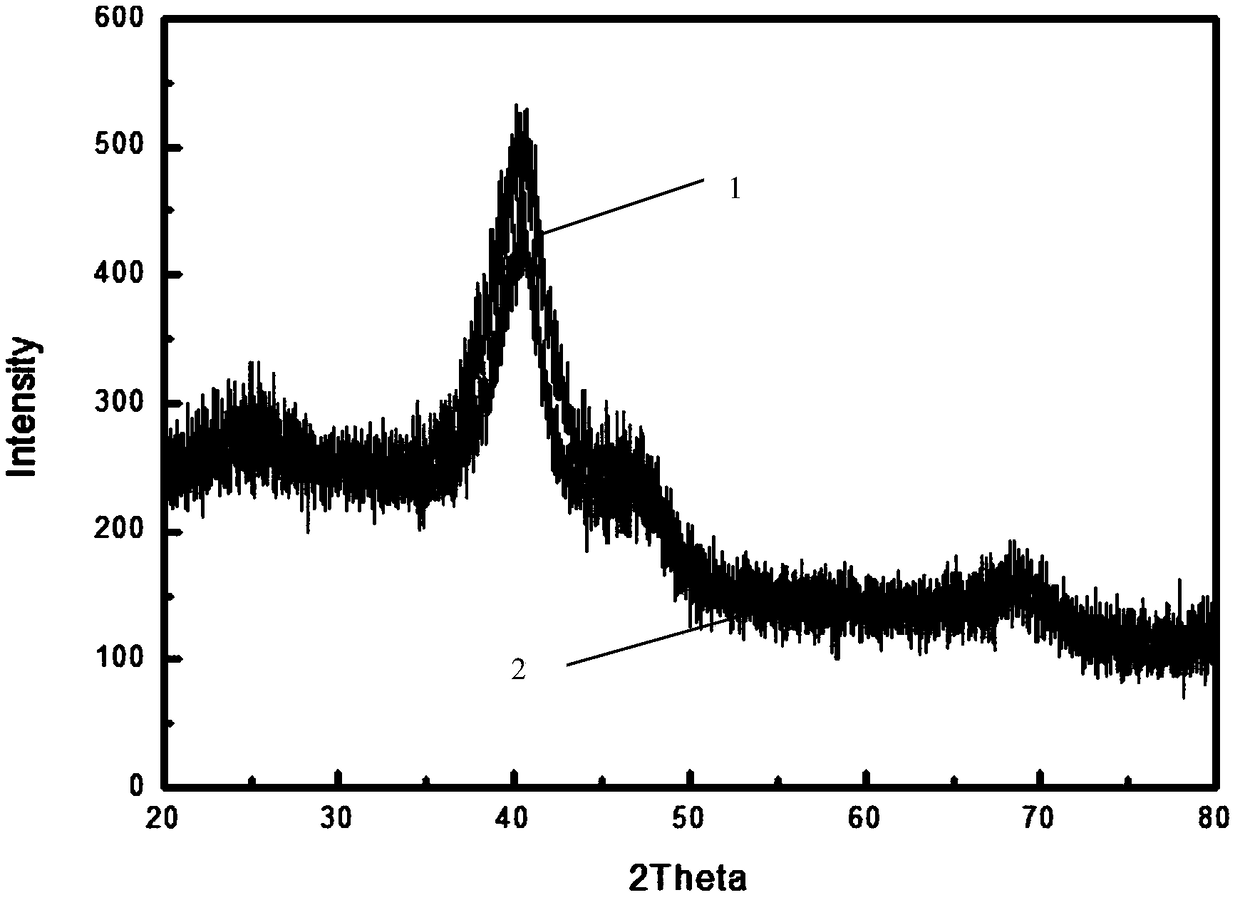

Image

Examples

Embodiment 1

[0034] A method for preparing a catalyst with a core-shell structure, using a microreactor and in the microreactor: preparing a carbon-supported metal core, using a polyhydric alcohol to reduce the shell metal, and then reacting the shell metal with the carbon-supported metal core to produce A core-shell catalyst was obtained.

[0035] Specifically include the following steps:

[0036] S1. According to the molar ratio of the metal salt and citric acid being 1:1-1:7, configure a mixed aqueous solution of the metal salt and citric acid to obtain a solution a with a concentration of 0.01-0.1 g / ml;

[0037] S2, using KOH, NaOH, ethylamine, triethylamine and an aqueous alkali solution b with a concentration of 5g / L-10g / L in ammonia;

[0038] S3. Use intermediate frequency ultrasound to disperse one or more of carbon black XC-72, carbon black AC30 and carbon black ECP600 to prepare the slurry c with a concentration of 0.1g / L-1g / L, and control the time of ultrasound In 30-60min;

...

Embodiment 2

[0045] S1, respectively weighing 0.109g copper sulfate pentahydrate and 0.263g citric acid were dissolved in 50mL water to obtain solution a;

[0046] S2, weigh again 0.270gKOH and dissolve in 30mL water to obtain alkaline aqueous solution b;

[0047] S3, ultrasonically disperse 0.12g of carbon black AC30 in 100mL of water, and ultrasonically until the carbon black has no fine particles, to obtain slurry c;

[0048] S4. Put the solution a and the slurry c into the microreactor at a flow rate of 2.5mL / min and 5mL / min respectively, and then mix them slightly with the aqueous alkali solution b at a flow rate of 1.5mL / min, and control the reaction temperature and time to 20°C respectively and 15min, after the reaction, the solution was added with 40mg sodium borohydride to obtain solution d;

[0049] S5. Use a positive pressure filter to filter the solution d, then wash with water 4-5 times, and finally use a vacuum drying oven to control the drying temperature at 60°C for 12 hou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com