Direct carbon solid oxide fuel cell

A solid oxide, fuel cell technology, used in solid electrolyte fuel cells, fuel cell components, battery electrodes, etc. Carbon fuel use efficiency and other issues, to avoid fluidized bed equipment, intensive battery structure, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

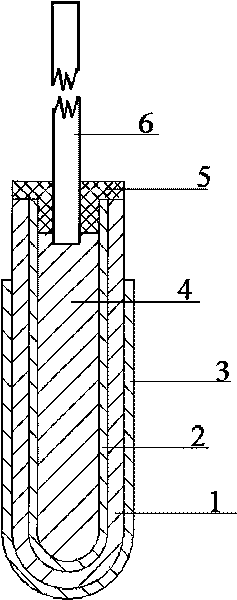

[0043] Weigh a certain quality of YSZ powder, add pure water according to the mass ratio of YSZ and pure water to 1:10, and ball mill to obtain a uniformly dispersed slurry, and use the grouting method to prepare a tubular YSZ electrolyte tube support body 1 green body . Put the green body in a high-temperature electric furnace and sinter in air at 1600°C for 4 hours to obtain a dense electrolyte tube, which is about 3.5 cm long, 0.8 cm in inner diameter, and 0.3 mm in wall thickness.

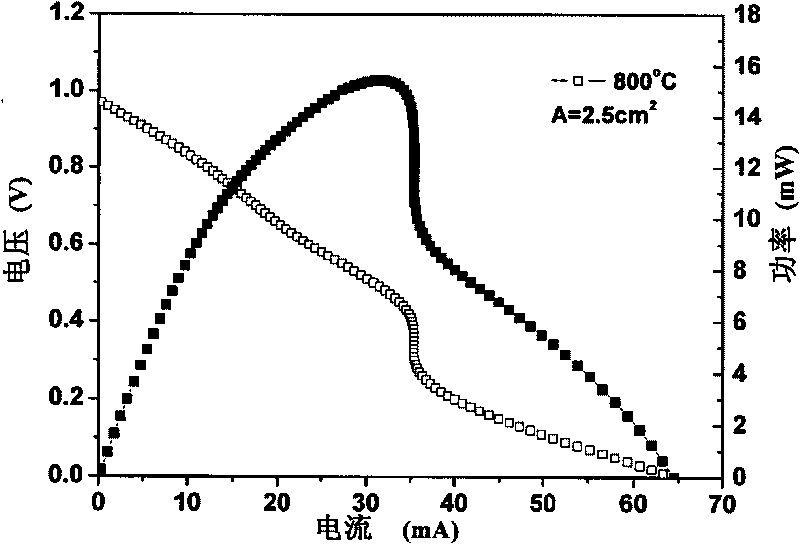

[0044] Apply the purchased DAD-87 silver conductive adhesive (produced by Shanghai Synthetic Resin Research Institute) with a paintbrush to all areas (thickness about 35um) below the inner wall and outer wall of the electrolyte tube support body 1 below 25mm from the nozzle, and dry it in a high-temperature oven , placed in a high-temperature electric furnace at 600°C for sintering in air for 2h to prepare the anode and cathode. The effective area of the cathode is 2.5cm 2 . The activated ...

Embodiment 2

[0048] Weigh a certain quality of YSZ powder, add pure water according to the mass ratio of YSZ and pure water to 1:10, and ball mill to obtain a uniformly dispersed slurry, and use the grouting method to prepare a tubular YSZ electrolyte tube support body 1 green body . Put the green body in a high-temperature electric furnace and sinter in air at 1600°C for 4 hours to obtain a dense electrolyte tube, which is about 3.5 cm long, 0.8 cm in inner diameter, and 0.3 mm in wall thickness.

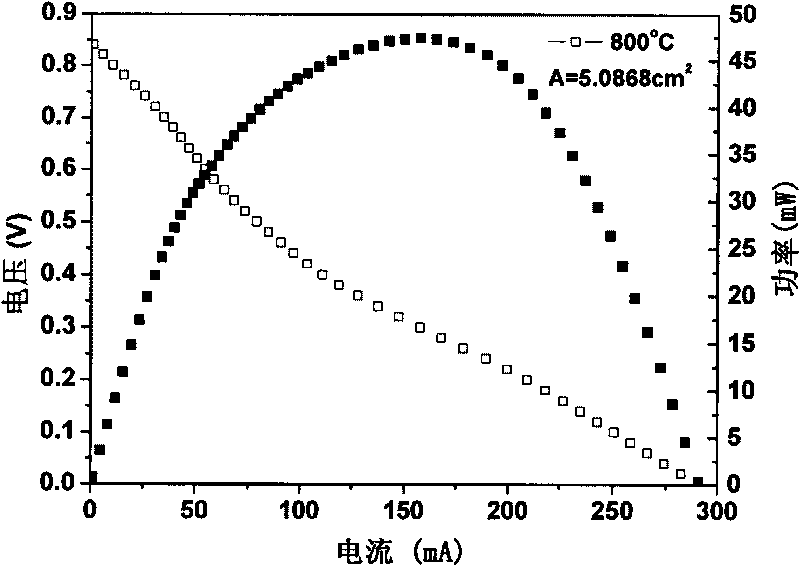

[0049] Apply the purchased DAD-87 silver conductive adhesive (produced by Shanghai Synthetic Resin Research Institute) with a paintbrush to all areas (thickness about 34um) below the inner wall and outer wall of the electrolyte tube support 1 that are 25mm away from the nozzle, and dry in a high-temperature oven , placed in a high-temperature electric furnace at 600°C for sintering in air for 2h to prepare the anode and cathode. The effective area of the cathode is 5.08cm 2 . The graphite ...

Embodiment 3

[0053] Weigh a certain quality of YSZ powder, add pure water according to the mass ratio of YSZ and pure water to 1:10, and ball mill to obtain a uniformly dispersed slurry, and use the grouting method to prepare a tubular YSZ electrolyte tube support body 1 green body . Put the green body in a high-temperature electric furnace and sinter in air at 1600°C for 4 hours to obtain a dense electrolyte tube, which is about 3.5 cm long, 0.8 cm in inner diameter, and 0.3 mm in wall thickness.

[0054] Mix gadolinium-stabilized cerium oxide (GDC) and Ag powder uniformly in a mass ratio of 55:45, and then mix the mixture with an organic binder in a mass ratio of 1:1; the organic binder raw material is composed of ethyl cellulose and Terpineol composition, wherein, the mass ratio of ethyl cellulose and terpineol is 1:9. The mixture of the above components is fully ground to obtain a uniformly dispersed anode slurry. The anode slurry was painted on the inner wall of the electrolyte tube...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com