Method for treating low-concentration difficult-to-degrade organic wastewater through adsorption-electrocatalysis combination

A technology of organic wastewater and electrocatalysis, applied in the direction of adsorption water/sewage treatment, chemical instruments and methods, water/sewage treatment, etc., can solve the problems of mass transfer control difficulties, avoid secondary pollution, improve degradation effect, and solve The effect of mass transfer problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

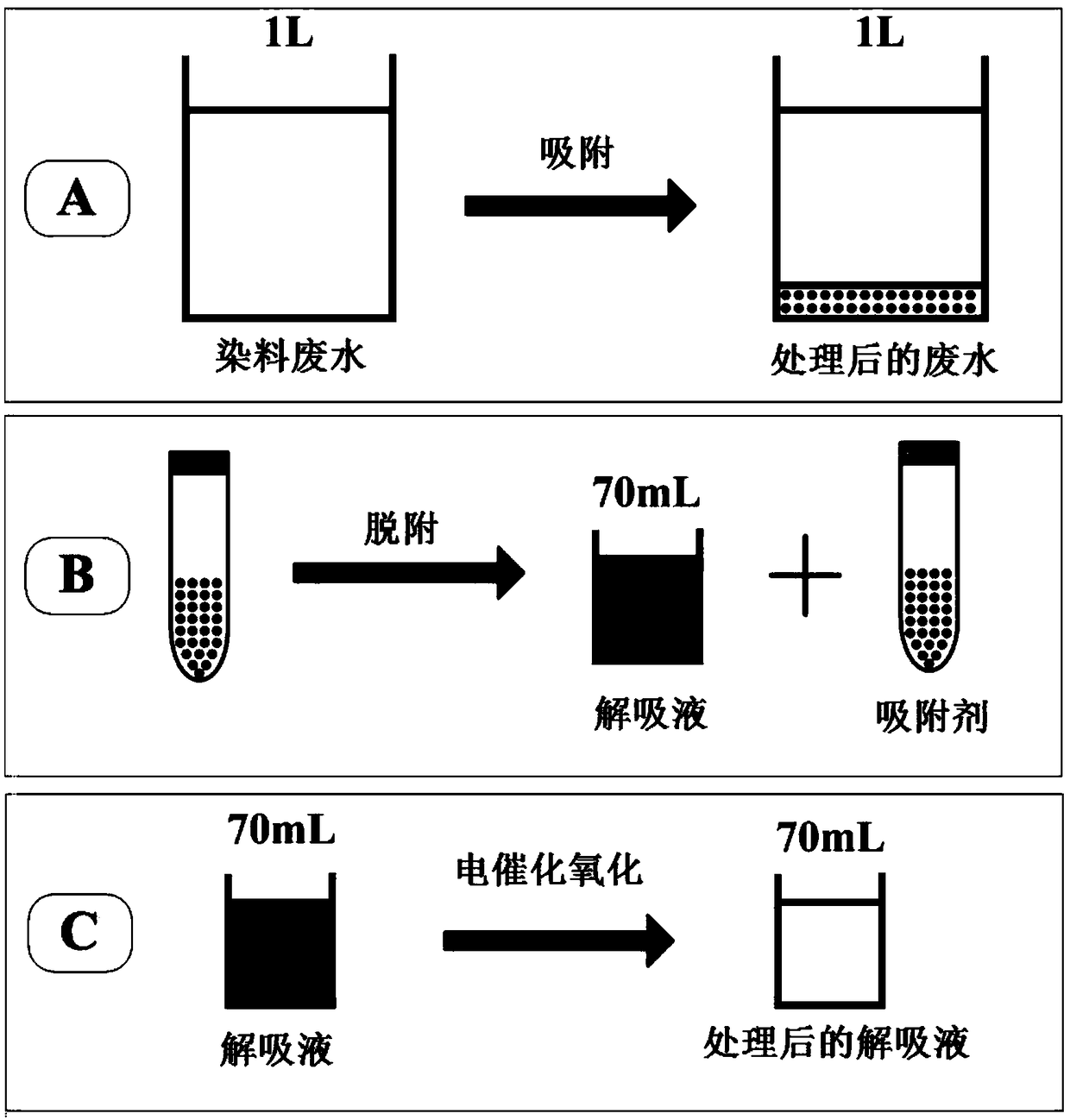

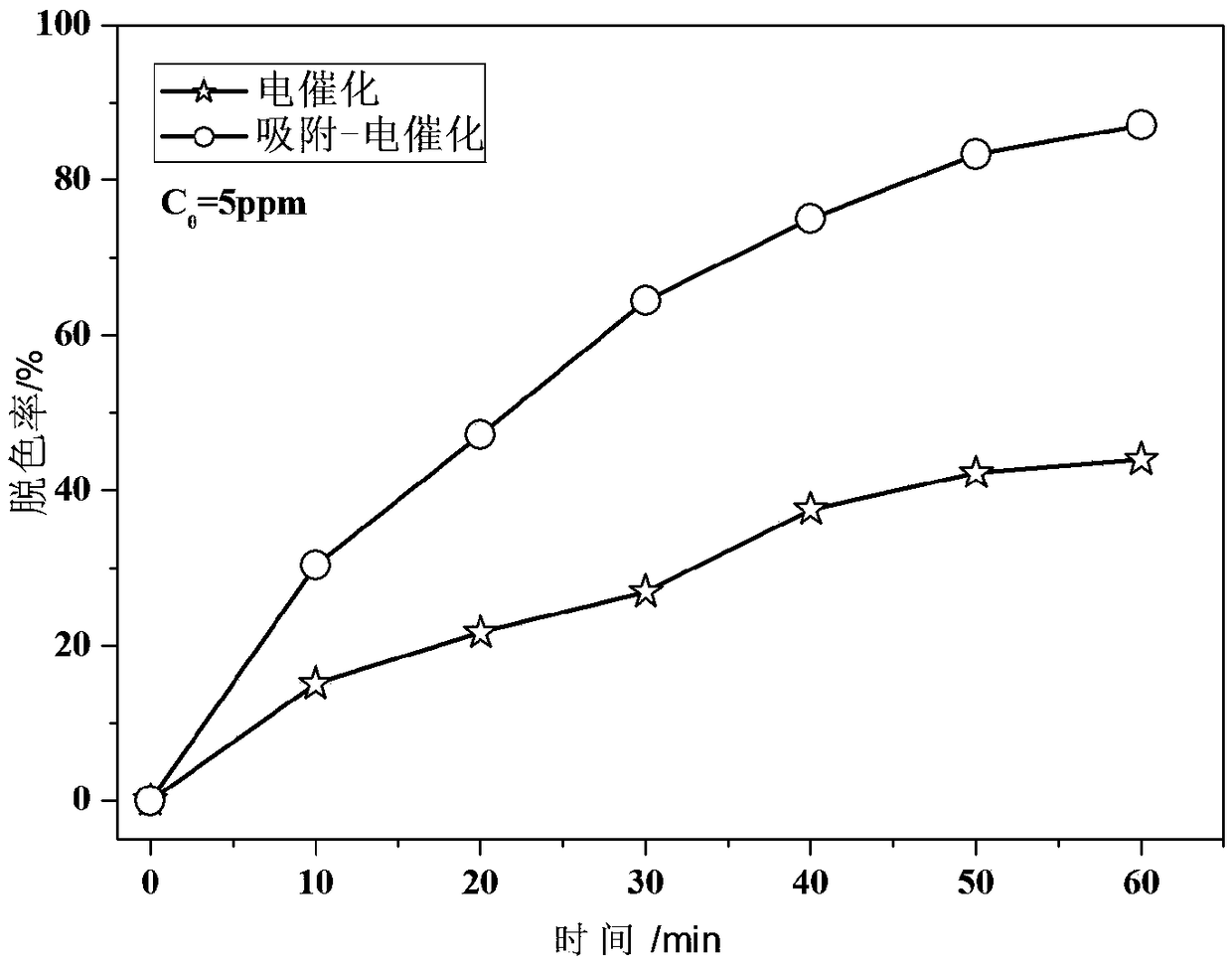

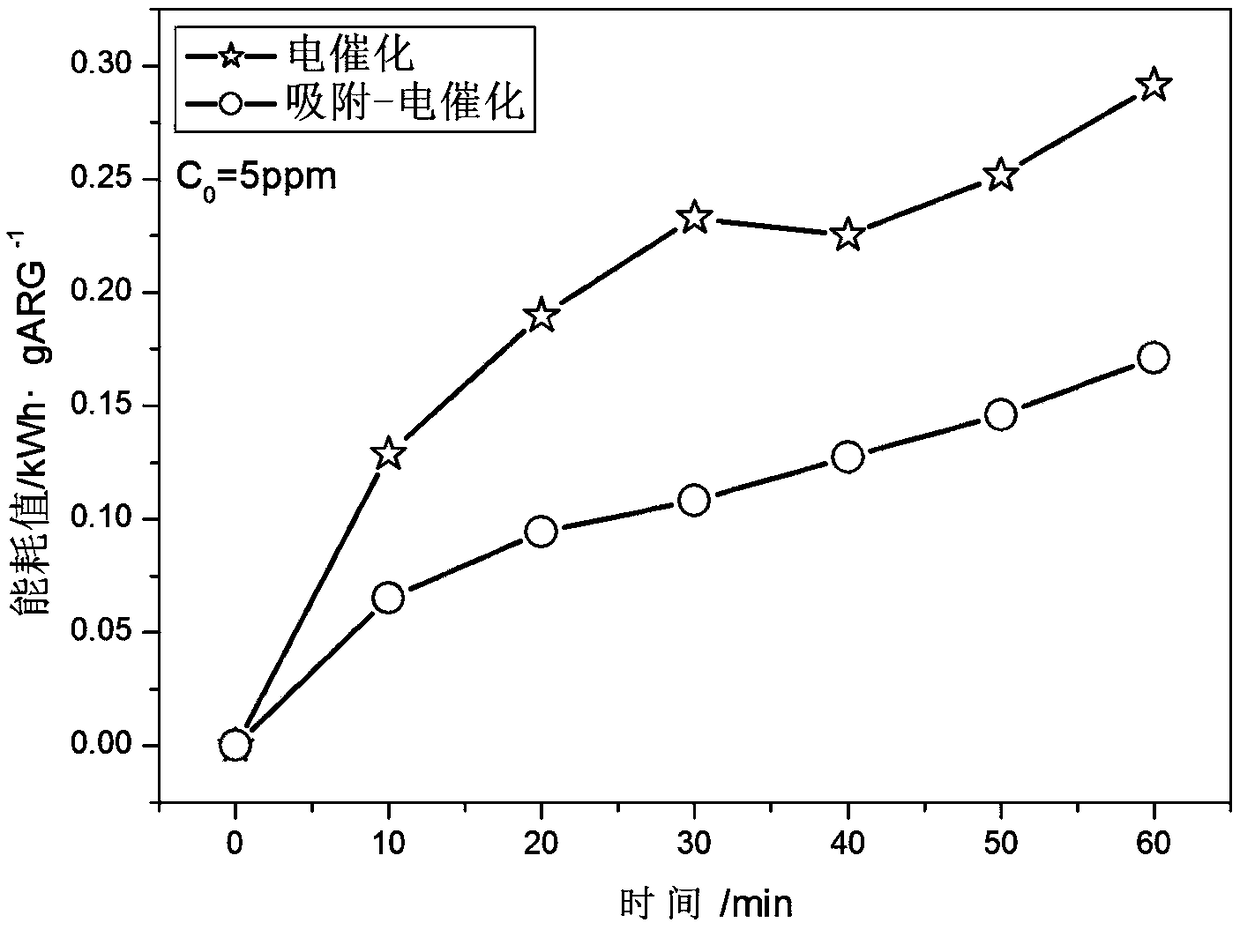

[0040] 1) Dilute the adsorbent particles according to 2.0g·L -1 The proportion added to 1L concentration is 5mg·L -1 In the simulated wastewater of ARG, it was adsorbed for 60min under stirring state, and the above suspension was centrifuged at 4000rpm to separate the solid and liquid. The separated adsorbent enters the subsequent desorption process.

[0041] 2) Add the adsorbent separated in 1) to 70mL of 0.1mol L-1 in NaOH solution. Desorb for 20 minutes in a stirred state, let it stand for sedimentation, filter and separate the adsorbent, and perform electrocatalytic oxidation treatment on the separated desorption liquid.

[0042] 3) Add the desorption liquid separated in 2) into the electrocatalytic reactor, use the titanium matrix lead dioxide electrode as the water treatment anode, and use the copper sheet as the water treatment cathode, and perform electrocatalytic oxidation on the desorption liquid under the condition of power supply deal with. Before the electroca...

Embodiment 2

[0051] 1) Dilute the adsorbent particles according to 3.0g·L -1 The proportion added to 1L concentration is 10mg·L -1 In the simulated wastewater of ARG, it was adsorbed for 60min under stirring state, and the above suspension was centrifuged at 4000rpm to separate the solid and liquid. The separated adsorbent enters the subsequent desorption process.

[0052] 2) Add the adsorbent separated in 1) to 70mL of 0.1mol L -1 in NaOH solution. Desorb for 20 minutes in a stirred state, let it stand for sedimentation, filter and separate the adsorbent, and perform electrocatalytic oxidation treatment on the separated desorption liquid.

[0053] 3) Add the desorption liquid separated in 2) into the electrocatalytic reactor, use the titanium matrix lead dioxide electrode as the water treatment anode, and use the copper sheet as the water treatment cathode, and perform electrocatalytic oxidation on the desorption liquid under the condition of power supply deal with. Before the electr...

Embodiment 3

[0057] 1) Dilute the adsorbent particles according to 5.0g·L -1 The proportion added to 1L concentration is 20mg·L -1 In the simulated wastewater of ARG, it was adsorbed for 60min under stirring state, and the above suspension was centrifuged at 4000rpm to separate the solid and liquid. The separated adsorbent enters the subsequent desorption process.

[0058] 2) Add the adsorbent separated in 1) to 70mL of 0.1mol L -1 in NaOH solution. Desorb for 20 minutes in a stirred state, let it stand for sedimentation, filter and separate the adsorbent, and perform electrocatalytic oxidation treatment on the separated desorption liquid.

[0059] 3) Add the desorption liquid separated in 2) into the electrocatalytic reactor, use the titanium matrix lead dioxide electrode as the water treatment anode, and use the copper sheet as the water treatment cathode, and perform electrocatalytic oxidation on the desorption liquid under the condition of power supply deal with. Before the electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com