Hierarchical pore structure high polymer material and preparation method thereof

A polymer material and multi-level pore technology, applied in the field of multi-level pore structure polymer materials and their preparation, can solve the problems of high material waste rate, high drying energy consumption, surfactant leakage, etc., and achieve high product qualification rate , low drying energy consumption, fast drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

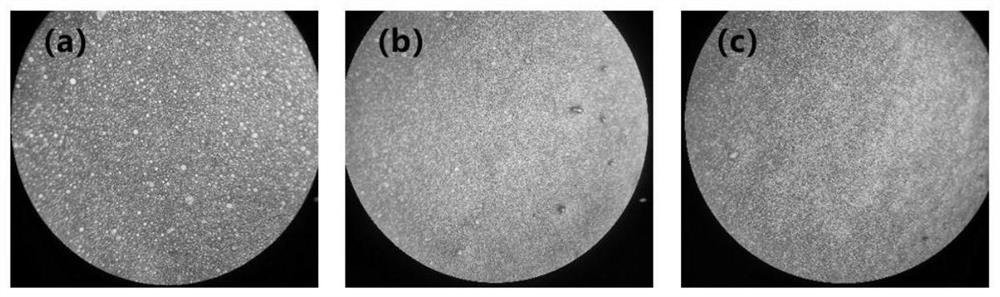

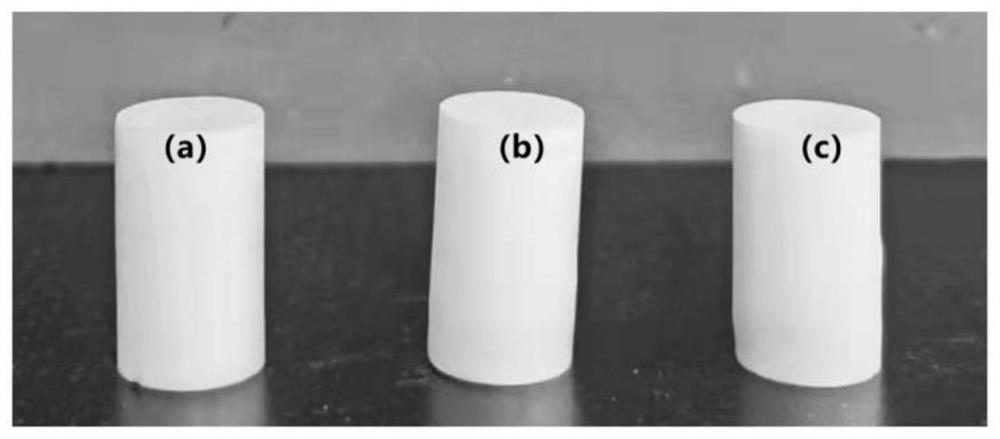

Embodiment 1

[0039] Add 0.40g of hydrophobic silica particles and 0.40g of dibenzoyl peroxide into the beaker, then add 12.86g of p-chlorostyrene, 2.88g of divinylbenzene, 0.58g of trimethylolpropane triacrylate, 2.88 g polylactic acid (molecular weight: 10,000), stir evenly with a PTFE stirrer to form a uniform reaction mixture; add 80 g of deionized water to the mixture, and stir with a dispersion plate for 10 minutes to form a viscous, stable gel emulsion ; Thermally polymerize the gel emulsion in a water bath, react at room temperature for 8 hours, heat up to 70°C for 12 hours; dry at 80°C to obtain a complete appearance, uniform and delicate density of 0.20g / cm 3 Hierarchical porous polymer materials.

Embodiment 2

[0041] Add 0.80g of hydrophobic silica particles and 0.80g of azobisisobutyronitrile into the beaker, then add 25.73g of α-methylstyrene, 5.76g of diallyl phthalate, and 1.16g of trimethylolpropane in sequence Trimethacrylate, 5.76g polyvinyl chloride paste resin (molecular weight is 62,000), and the dispersing plate is stirred evenly to form a uniform reaction mixture; 60g deionized water is added to this mixture, and the emulsifier is stirred for 15 minutes to form Viscous and stable gel emulsion; thermally polymerize the gel emulsion in a water bath, react at room temperature for 8 hours, heat up to 80°C for 12 hours; dry at 80°C to obtain a complete appearance, uniform and delicate density of 0.40g / cm 3 Hierarchical porous polymer materials.

Embodiment 3

[0043] Add 1.20g of hydrophobic silica particles and 1.20g of dicumyl peroxide into the beaker, then add 35.72g of 4-methylstyrene, 8.64g of ethylene glycol dimethacrylate, and 1.73g of cyanuric acid Triallyl ester, 8.84g polyacrylamide (molecular weight is 15,000), the PTFE stirrer stirs evenly, forms the uniform reaction mixture; Adds 40g deionized water to this mixture, emulsifier stirs 20 minutes, forms viscose Thick and stable gel emulsion; thermally polymerize the gel emulsion in a water bath, react at 40°C for 4 hours, heat up to 90°C for 10 hours; dry at 80°C to obtain a complete appearance, uniform and delicate density of 0.60g / cm 3 Hierarchical porous polymer materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com