Full-continuous flow production process of phosphoric acid tri(1-chlorine-2-propyl) ester

A production process, a fully continuous technology, applied to compounds of elements of Group 5/15 of the periodic table, organic phosphorus compounds, chemical instruments and methods, etc., can solve problems such as low production efficiency, rising production costs, and complex production processes , to achieve the effect of saving plant land and cost, small footprint and excellent quality

Active Publication Date: 2018-11-13

ZHEJIANG WANSHENG

View PDF25 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The disadvantages of this method are: the one, need to add extra water washing operation, increased time cost, also increased waste water, neither economical nor environmental protection; the 2nd, hydroxylamine hydrochloride and product are incompatible, and reaction process is slow, may cause Incomplete removal of aldehyde impurities reduces product quality; third, the cost of hydroxylamine hydrochloride is high, and the HCl part in it will decompose TCPP finished products and reduce the yield

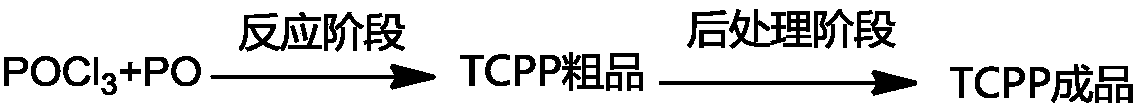

[0028] 1. Failure to realize the simple and efficient production process from raw materials to qualified commercially available finished products, the production process is complex and requires multiple stops and waits;

[0029] 2. The reaction stage and the post-processing stage are not continuously integrated, but two independent processes, and a set of equipment is not used to directly realize the production and post-processing process of TCPP, resulting in low production efficiency;

[0030] 3. The total process time is too long and the production efficiency is low;

[0031] 4. It is necessary to add additional steps to deal with the aldehyde impurities in the finished product, which will lead to an increase in production costs and easy introduction of new impurities, which will affect the quality of the finished product and subsequent use;

[0032] 5. The finished product will have different degrees of acid reflux, which will affect downstream use;

[0033] 6. A large amount of wastewater with high phosphorus content is produced in the post-treatment process, which is expensive to treat and difficult to recycle

[0034] In the prior art, it is impossible to obtain a stable acid value (no acid reversion), a content of aldehydes of 0 (free of aldehydes), and a metal cation corresponding to the catalyst (the content of the metal cation is 0 ) of the TCPP finished product, and have not developed a process that is simple, efficient, environmentally friendly, and can ensure the high quality of the finished product, that is, the reaction process and the post-processing process are continuously integrated and matched together, and the raw materials are simply and efficiently obtained from the raw materials. The standard TCPP finished product can also take into account the high quality of the finished product (no aldehyde impurities, no acid backlash), process environmental protection (reduce the phosphorus content in wastewater and the total amount of wastewater) and low cost (no additional steps for removing impurities)

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0224]

[0225]

[0226]

[0227]

[0228]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Login to View More

Abstract

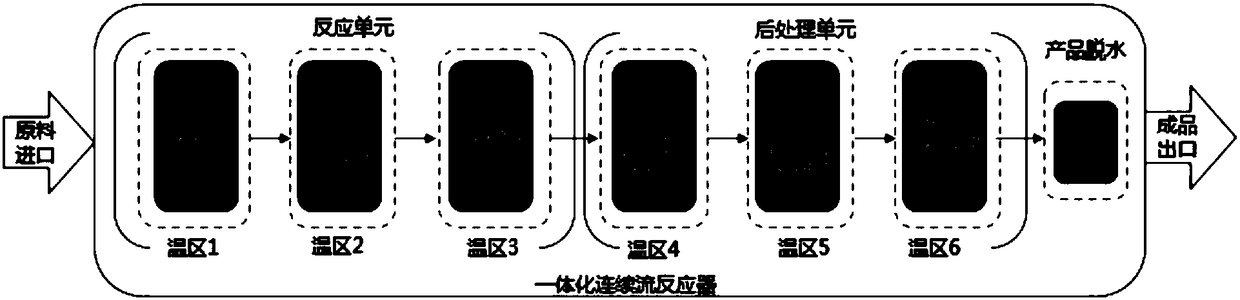

The invention relates to a full-continuous flow production process of a phosphoric acid tri(1-chlorine-2-propyl) ester. According to the process, a reaction period and an aftertreatment period are adopted as a whole process which is continuously carried out without interruption, raw materials, namely phosphorus oxychloride, epoxypropane and a catalyst are continuously fed into the feeding hole ofa reactor, a finished product of the phosphoric acid tri(1-chlorine-2-propyl) ester which meets marketing standards is continuously prepared at the outlet of the reactor, and the purpose that a high-quality finished product of the phosphoric acid tri(1-chlorine-2-propyl) ester (TCPP) is rapidly prepared is achieved. By adopting the full-continuous flow production process provided by the invention,efficient production, high-quality finished products and stable storage are achieved, the TCPP finished product is free of aldehyde impurity, free of acid regurgitation and free of metallic cation corresponding to the catalyst, and in addition, the process is small in wastewater amount, low in phosphorus containing, beneficial to environment protection and applicable to security industrial production.

Description

technical field [0001] The invention relates to the field of chemical additive flame retardants, in particular to a continuous flow production process for preparing tris(1-chloro-2-propyl) phosphate (TCPP) finished products. Background technique [0002] Tris(1-chloro-2-propyl) phosphate, also known as tris-(2-chloroisopropyl) phosphate, trichloropropyl phosphate, etc., referred to as TCPP, is a phosphorus-based additive flame retardant , its flame retardant effect is remarkable, widely used in polyurethane flexible foam, rigid foam, epoxy resin, phenolic resin and other polymer materials. [0003] The production process of TCPP mainly includes the reaction stage and the post-treatment stage. The brief process is as follows: [0004] [0005] Known to those skilled in the art, the current process of preparing TCPP in industry is as follows: under anhydrous and oxygen-free conditions, the catalyst is dissolved in raw material phosphorus oxychloride (POCl 3 ), slowly add ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C07F9/09

CPCC07F9/091

Inventor 李旭锋褚昭宁吕云兴陶光撑马兵刘辰

Owner ZHEJIANG WANSHENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com