Riser spiral-flow type falling-film evaporator for refrigerating air conditioner

A falling-film evaporator and falling-film evaporation technology, applied in evaporators/condensers, refrigerators, refrigeration components, etc., can solve problems such as dry evaporation and insufficient refrigerant flow, reduce liquid holding capacity and save power consumption , the effect of improving heat transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

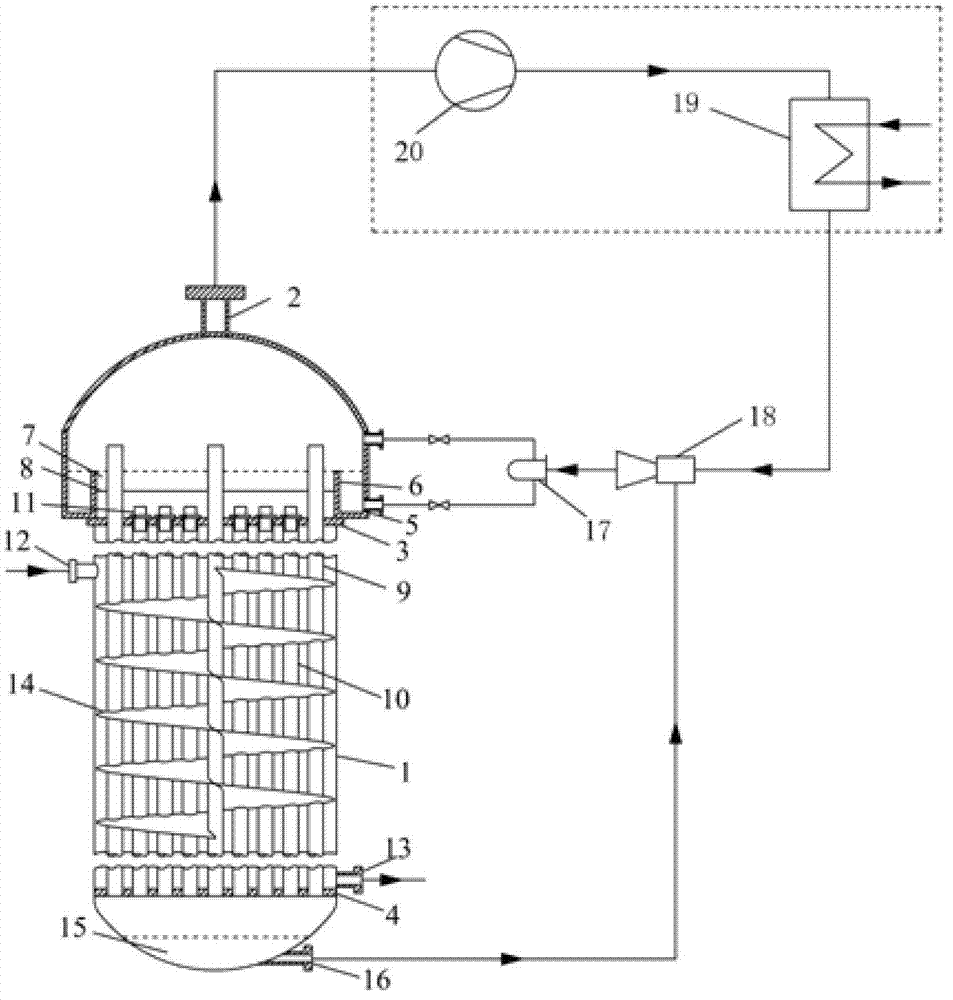

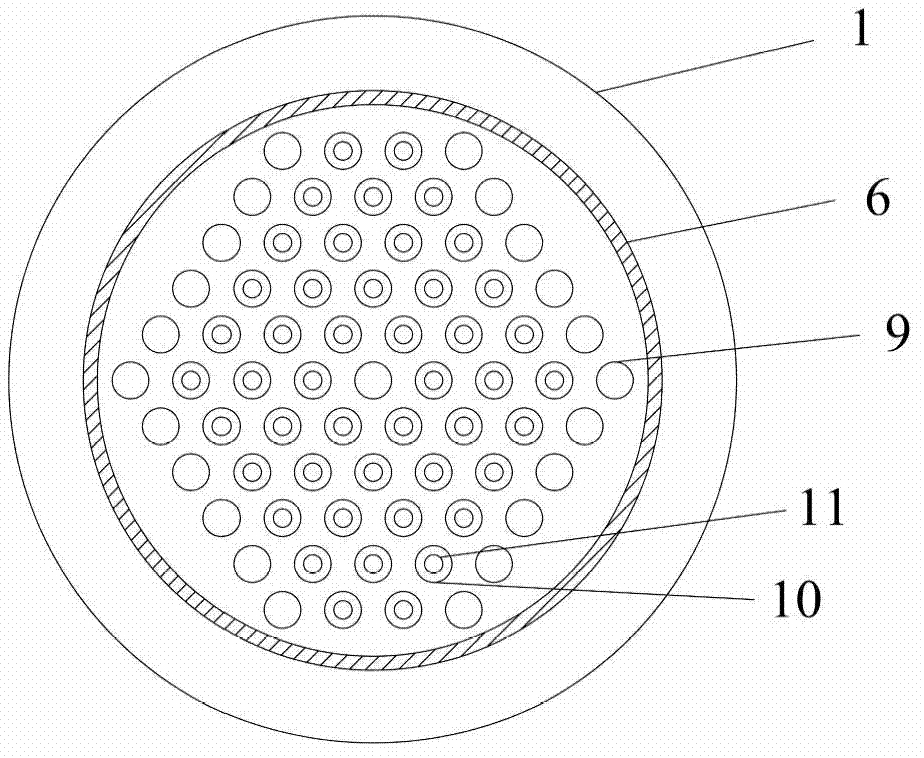

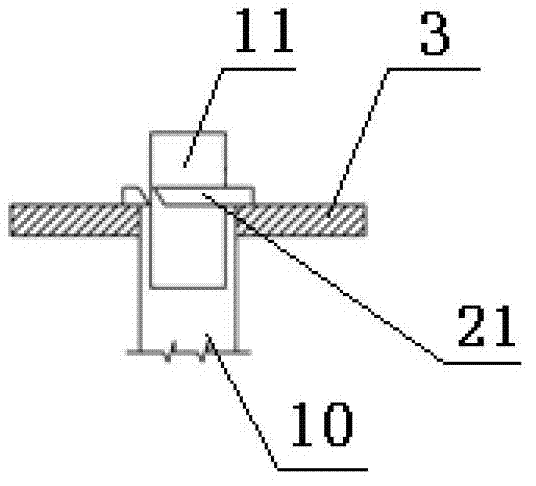

[0020] Such as figure 1 As shown, a standpipe swirl type falling film evaporator for refrigeration and air conditioning of the present invention comprises a shell 1, placed in the center of the shell 1 and a refrigerant vapor delivery tube bundle 9 arranged circumferentially along the inner wall of the shell 1. The falling film evaporation tube bundle 10 surrounded by the steam delivery tube bundle 9, the refrigerant steam delivery tube bundle 9 and the falling film evaporation tube bundle 10 are both vertically arranged in the shell 1, and there are helical folds arranged in a spiral along the vertical direction inside the shell 1 The flow plate 14, the refrigerant vapor delivery tube bank 9 and the falling film evaporation tube bank 10 pass through the through holes on the spiral baffle plate 14, and the upper tube plate 3 and the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com