Method for enhanced capture of acid gas by cooperation of supergravity and nanofluid technology

A technology of acidic gas and nanofluid, applied in chemical instruments and methods, membrane technology, gas treatment, etc., can solve the problems of low absorption efficiency and low gas-liquid mass transfer efficiency, reduce solvent usage, increase gas-liquid transfer Quality area, enhanced strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

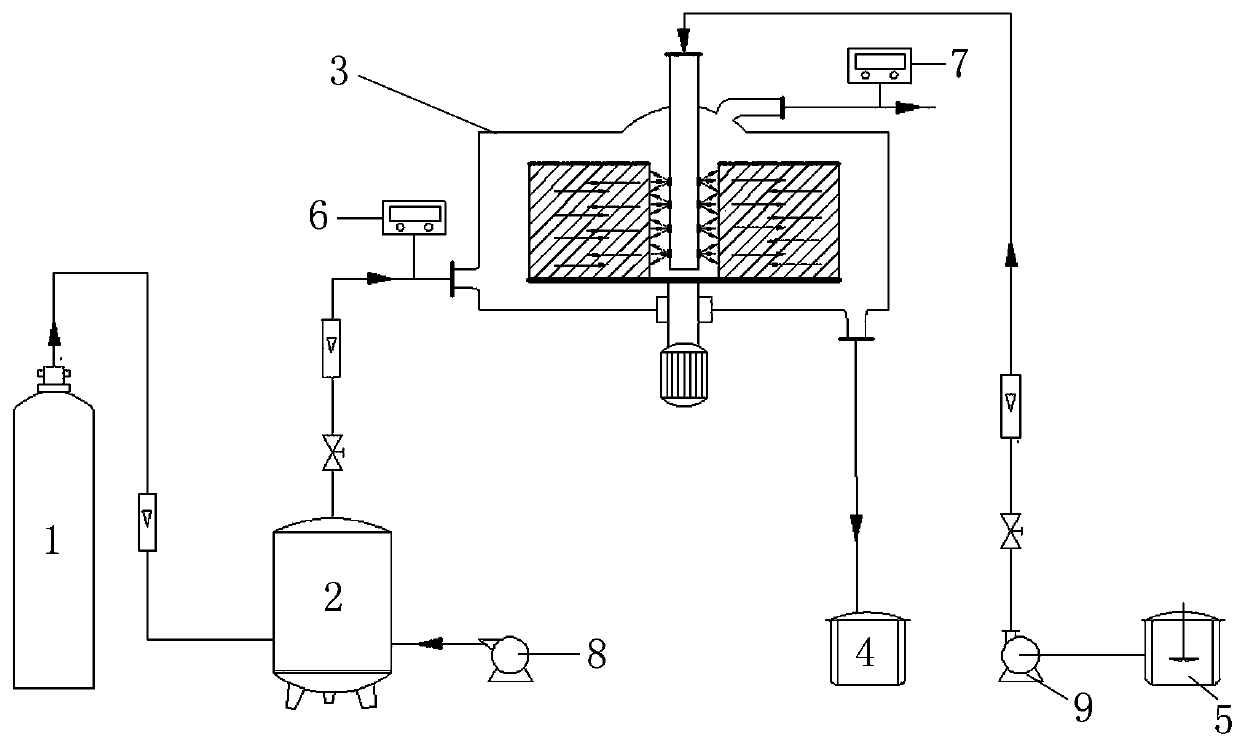

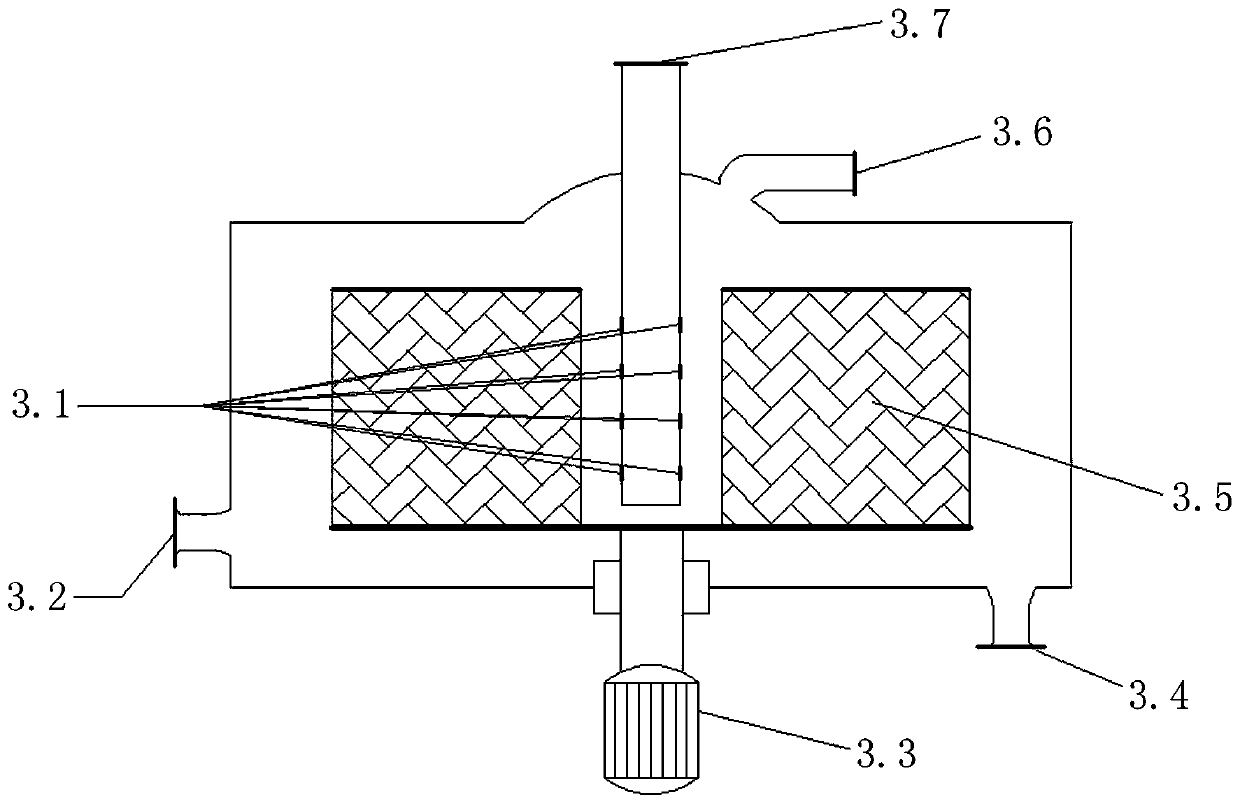

[0022] Example 1: A method of supergravity synergistic nanofluid technology to strengthen the capture of acid gas. The nano-amine functionalized mesoporous structure particles, surfactant and absorbent solution are prepared into nanofluid and placed in the stirring tank 5, and the acid gas The acid gas in the steel cylinder 1 is buffered and mixed by the buffer tank 2, and the gas mixture containing the acid gas enters from the air inlet 3.2 of the supergravity rotating packed bed 3, and the nanofluid in the stirring tank 5 is transferred from the supergravity rotating packed bed by the centrifugal pump 9. The liquid inlet 3.7 of 3 enters, and the two are countercurrently contacted in the supergravity rotating packed bed 3 to remove the acid gas, and the purified gas and the nanofluid absorbing the acid gas are passed through the gas outlet 3.6 and the outlet of the supergravity rotating packed bed 3 respectively. The liquid port 3.4 is discharged, and the nanofluid enters the ...

Embodiment 2

[0029] Example 2: A method of supergravity synergistic nanofluid technology to strengthen the capture of acid gas. The nano-amine functionalized mesoporous structure particles, surfactant and absorbent solution are prepared into nanofluid, and the gas mixture containing acid gas is prepared by super The inlet of the gravity rotating packed bed enters, and the nanofluid enters from the liquid inlet of the supergravity rotating packed bed through the centrifugal pump. The nanofluid of the gas is respectively discharged from the gas phase outlet and the liquid phase outlet of the high-gravity rotating packed bed; wherein the acid gas is H 2 S; the surfactant is cetyltrimethylammonium bromide CTAB; the absorbent is N-methyldiethanolamine MDEA; the nano-amine functionalized mesoporous structure particles are nano-amine functionalized SBA- 15.

[0030] Specific steps are as follows:

[0031] (1) Prepare absorbent base liquid: prepare 2L of 40wt% solution with N-methyldiethanolamin...

Embodiment 3

[0036] Example 3: A method of supergravity synergistic nanofluid technology to strengthen the capture of acid gas, the nano-amine functionalized mesoporous structure particles, surfactant and absorbent solution are formulated into nanofluid, and the gas mixture containing acid gas is prepared by super The inlet of the gravity rotating packed bed enters, and the nanofluid enters from the liquid inlet of the supergravity rotating packed bed through the centrifugal pump. The nanofluid of the gas is respectively discharged from the gas phase outlet and the liquid phase outlet of the high-gravity rotating packed bed; wherein the acid gas is SO 2 The surfactant is sodium dodecylbenzenesulfonate SDBS; the absorbent is diethylenetriamine (DETA); the nanometer amine functionalized mesoporous structure particles are nanometer amine functionalized MCM-48.

[0037] Specific steps are as follows:

[0038] (1) Preparation of absorbent base liquid: Diethylenetriamine (DETA) and deionized wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com