Amplification-effect-free continuous flow synthesis process of tert-butyl peroxy-2-ethylhexyl carbonate

A technology of tert-butyl carbonate and tert-butanol peroxide, applied in the field of chemistry, can solve the problems of consuming manpower and material resources for project development time, affecting process stability and reliability, affecting product quality and other problems, saving manpower and material resources and project development. Time and product quality are easy to control, and the production process is stable and reliable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

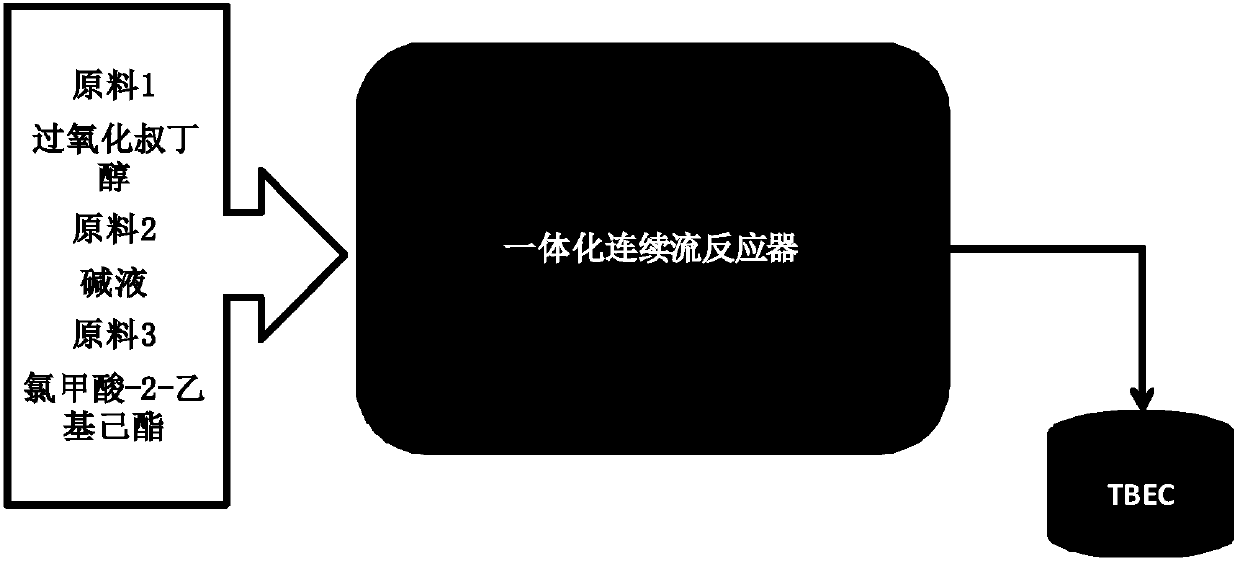

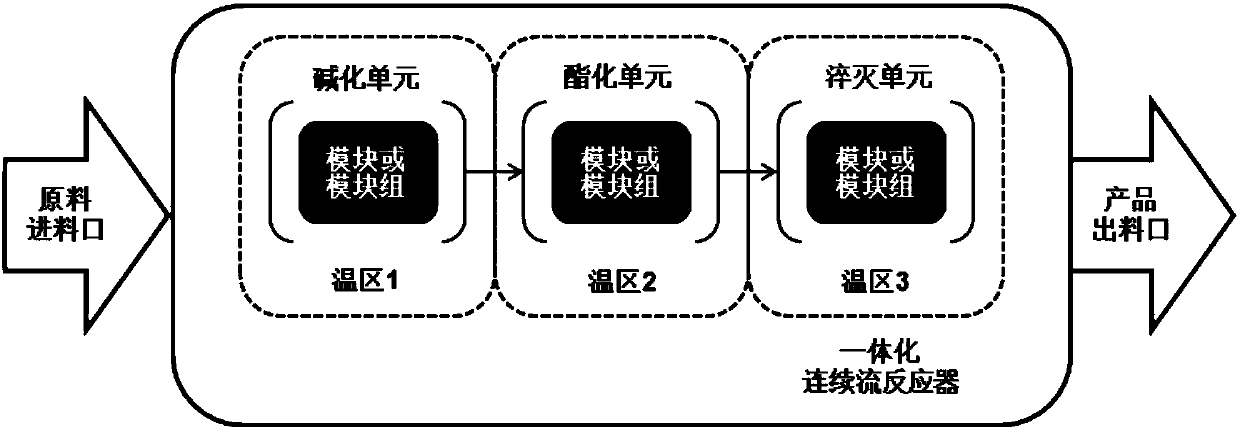

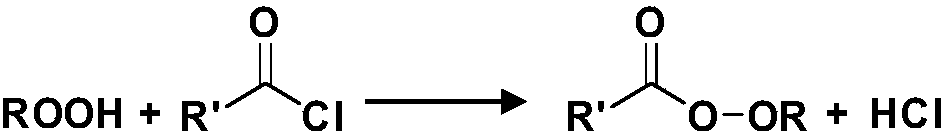

[0102] Such as figure 1 and figure 2 As shown, raw material 1 (tert-butanol peroxide) and raw material 2 (potassium hydroxide aqueous solution) are transported into temperature zone 1 with a constant flow pump, and flow through temperature zone 1 to react to generate intermediate tert-butyl potassium peroxide . Use a constant flow pump to transport raw material 3 (2-ethylhexyl chloroformate) into temperature zone 2, flow through temperature zone 2, and the reaction is complete. The reaction solution flowing out of temperature zone 2 enters temperature zone 3 to cool down to quench the reaction, and collect the reaction mother liquor. The mother liquor is separated, washed, etc., and tert-butyl peroxy-2-ethylhexyl carbonate can be obtained. The reaction parameters and results are as follows:

[0103] Table 1: Raw material flow rate, warm zone temperature, reaction time, content and yield

[0104]

Embodiment 2-19

[0106] Adopt the operation method of embodiment 1, investigated the reaction time, content and yield of preparing peroxy-2-ethylhexyl tert-butyl carbonate under different reaction parameters, each parameter condition and result are as shown in table 2 and 3 below.

[0107] Table 2: Raw material concentration and flow rate of Examples 2-19

[0108]

[0109]

[0110]

temperature T1 c (℃)

temperature T2 c (℃)

temperature T3 c (℃)

total reaction time d

content(%)

Yield (%)

2

5

50

35

180s

93.0

97.1

3

20

70

20

50s

93.5

97.3

4

11

55

15

150s

92.9

97.7

5

25

65

40

20s

95.5

97.0

6

30

60

30

110s

96.0

97.8

7

13

80

45

80s

95.2

97.2

8

9

78

23

100s

93.7

97.6

9

9

78

23

100s

93.7

97.6

10

7

90

31

30s

94.2

97.4

11

18

79

28

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com