Method for preparing nitrourea by utilizing microchannel reactor

A microchannel reactor, nitrourea technology, applied in chemical instruments and methods, preparation of urea derivatives, preparation of organic compounds, etc., can solve the problem of low impact sensitivity and friction sensitivity, nitrourea has not yet been seen, and increase safety. hidden dangers and other problems to achieve the effect of avoiding explosion, fast mass transfer rate, and reducing potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

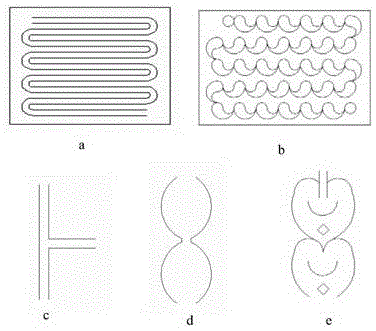

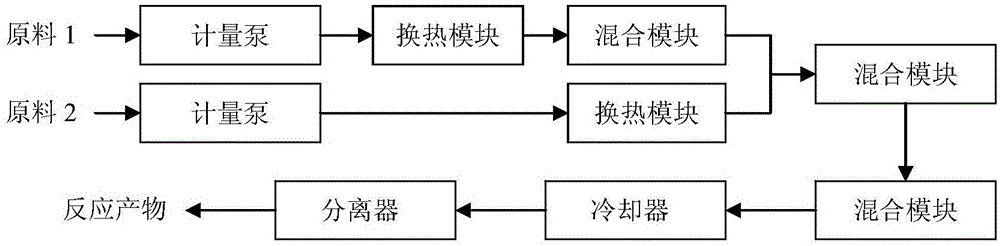

[0030] (1) A high-throughput microchannel reactor (straight channel module + spherical structure module) is used, connected according to the drawings in the manual. The number of modules is determined by the flow rate and reaction residence time. The material is injected into the heat exchange module through a metering pump, and the heat exchange The medium is heat transfer oil.

[0031] (2) Prepare a suspension of urea-concentrated sulfuric acid, design the molar ratio of urea:sulfuric acid to be 1:5, the reaction temperature is 15°C, and the reaction residence time is 60s. Control the flow rate of the sulfuric acid solution of urea sulfate to 2.0mL / min, control the flow rate of nitric acid to 0.4mL / min, the reaction temperature is 5°C, and the reaction residence time is 60s. After the sulfuric acid solution of urea sulfate passes through the mixing module, it enters the next mixing module and continues Mixing reaction, after the mixing is completed, the mixed product is cool...

Embodiment 2

[0034] (1) High-throughput microchannel reactor (straight channel module + Baguayang fish-shaped structure module), connected according to the drawings in the manual, the number of modules is determined by the flow rate and reaction residence time, and the material is injected into the heat exchange module through a metering pump , the heat transfer medium is heat transfer oil.

[0035] (2) Prepare a suspension of urea-concentrated sulfuric acid, design the molar ratio of urea:sulfuric acid to be 1:2, the reaction temperature is 10°C, and the reaction residence time is 100s. Control the flow rate of the sulfuric acid solution of urea sulfate to 2.0mL / min, control the flow rate of nitric acid to 0.4mL / min, the reaction temperature is 5°C, and the reaction residence time is 100s. After the sulfuric acid solution of urea sulfate passes through the mixing module, it enters the next mixing module and continues Mixing reaction, after the mixing is completed, the mixed product is coo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com