TDA dehydrating tower

A dehydration tower and tower body technology, which is applied in amino compound purification/separation, organic chemistry, fractionation, etc., and can solve problems such as plate efficiency drop, liquid flooding, and plate leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

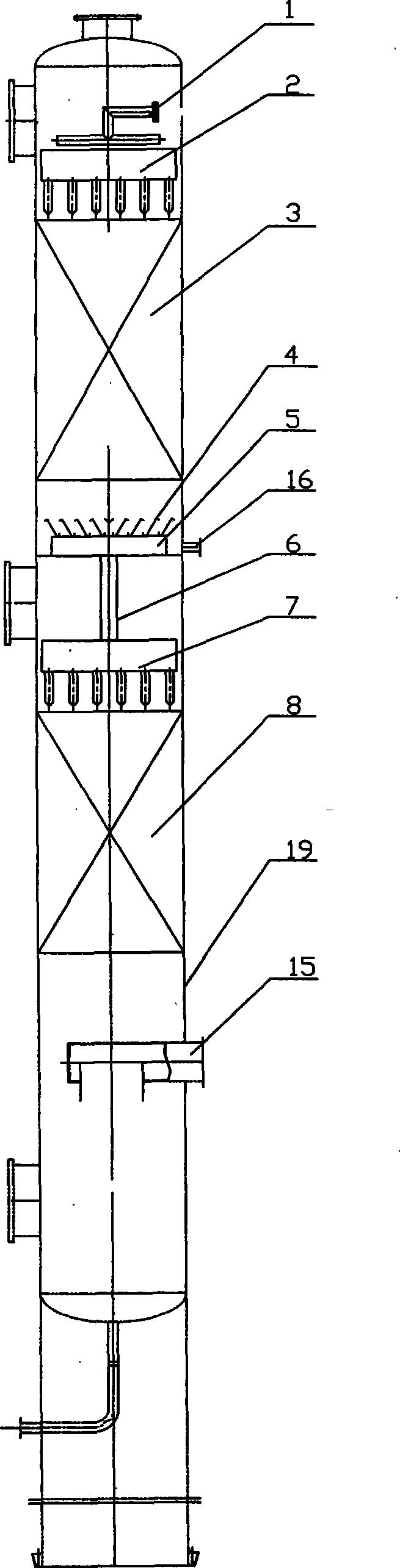

[0017] Embodiment 1, a kind of TDA dehydration tower, with reference to figure 1 , the top of the tower body 19 is provided with a reflux feed pipe 1, the bottom is provided with a recirculation gas phase inlet 15, the middle part is provided with a coarse TDA feed port 16, and the top of the tower body 19 is provided with an upper wall connected to the reflux feed pipe 1. Distribution tank 2, upper packing layer 3 is arranged under upper distribution tank 2, liquid collecting pan 4 is arranged under upper packing layer 3, liquid collecting tank 5 is fixed under liquid closing pan 4, and coarse TDA feed port 16 communicates with liquid collecting tank 5 , the bottom of the liquid collection tank 5 is provided with a downcomer 6 communicating with it, the downcomer 6 communicates with the lower distribution tank 7 below it, the lower distribution tank 7 is provided with a lower packing layer 8, the upper distribution tank 2 and the lower distribution tank 7 can evenly distribut...

Embodiment 2

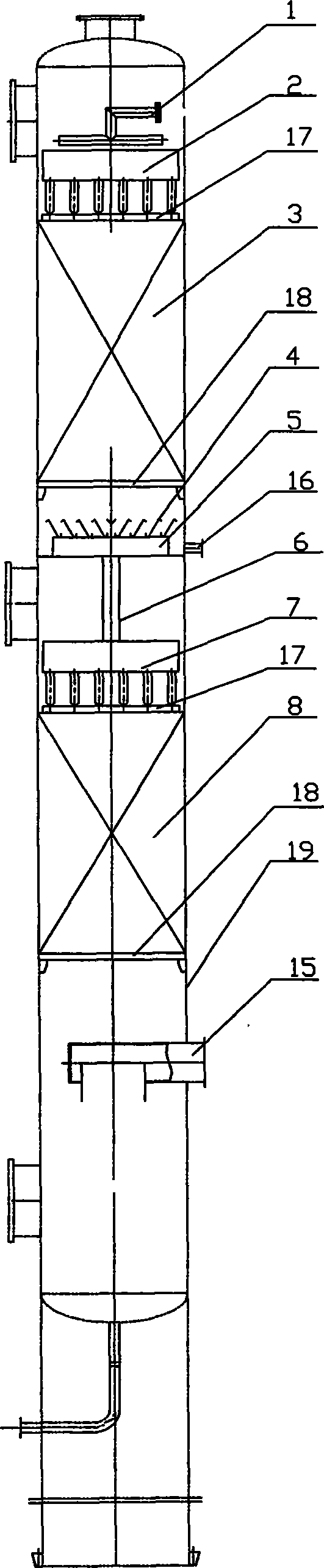

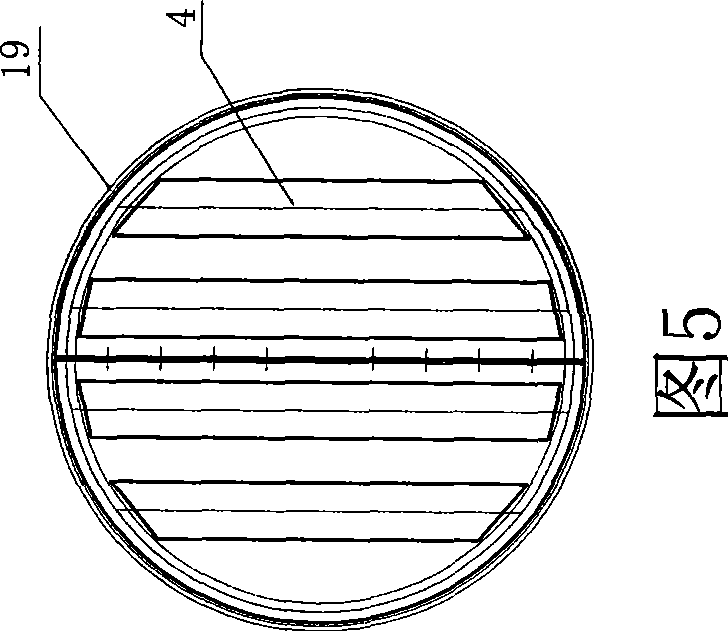

[0018] Embodiment 2, a kind of TDA dehydration tower, with reference to figure 2 , Fig. 3, Fig. 4, Fig. 5, are on the basis of embodiment 1, upper distribution groove 2 and lower distribution groove 7 are to be provided with secondary groove 10 below primary groove 9, and primary groove 9 is rectangular groove body There is a shallow groove 11 with jagged edges fixed in the middle, and the bottom of the rectangular groove is separated by a first-level distribution opening 12. The second-level groove 12 is composed of interconnected grooves 13, and the groove body 13 is directly opposite to the first-level distribution opening 12 above. The bottom surface of the tank body 13 is distributed with secondary distribution holes 14, and the upper packing layer 3 is a stainless steel wire mesh corrugation composed of stainless steel wire mesh corrugated sheets vertically arranged and stacked between the upper packing pressure ring 17 and the lower packing support ring 18. Disc-shaped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com