Clean technique for producing acrylate-hydroxy ester by adopting continuous process

A hydroxy acrylate, clean production technology, applied in the preparation of carboxylate, chemical instruments and methods, preparation of organic compounds, etc., can solve the problems of high labor intensity of operators, long reaction and holding time, unstable product quality, etc. , to achieve the effect of improving production safety, reducing uncontrollable factors and short response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

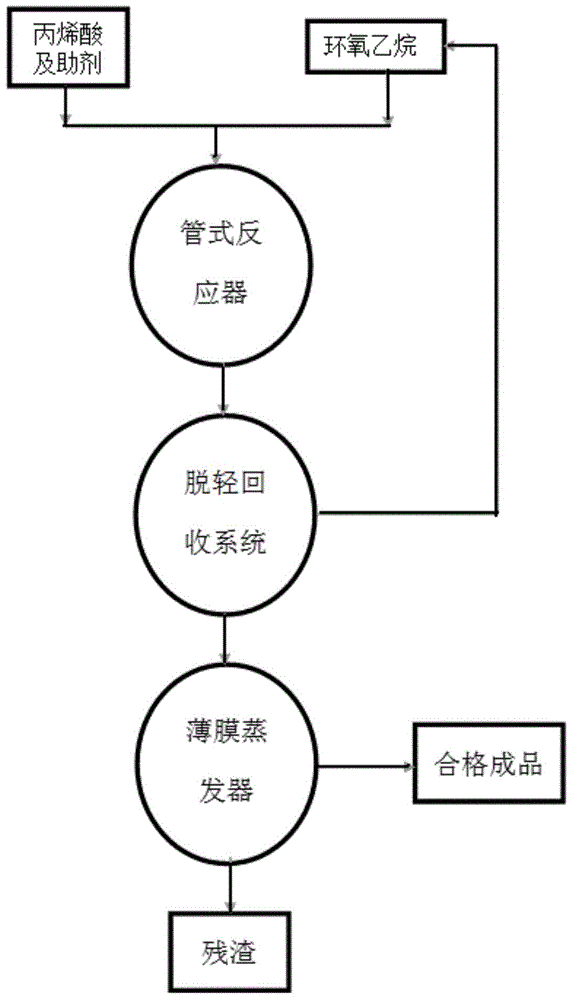

[0024] Such as figure 1 Shown, a kind of hydroxy acrylate continuous clean production process comprises the following steps:

[0025] 1). Dissolve 3 grams of catalyst and 3 grams of polymerization inhibitor in 500 grams of acrylic acid. After mixing and metering, press the molar ratio of acrylic acid to ethylene oxide to be 1:1.3 and pour it into the tubular reactor continuously; In the case of excess alkane, the reaction proceeds rapidly.

[0026] 2). After the reaction is completed, the ethylene oxide is recovered after light removal, and then enters the evaporator continuously to obtain the final product, and the recovered ethylene oxide can be recycled.

[0027] In step 1), the reaction temperature is 80°C, the pressure is 0.6Mpa, and the residence time is 60min;

[0028] In step 2), the delight recovery temperature is 65°C, the pressure is -0.095Mpa, and the residence time is about 20min; the evaporator temperature is 90°C, the operating pressure is 200torr (absolute pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com