Large-scale detachable tray liquid distributor

A liquid distributor and liquid distribution technology, applied in the direction of distillation separation, separation methods, chemical instruments and methods, etc., can solve problems such as production troubles, achieve the effects of low overall height, overcome amplification effect, and small liquid holding capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

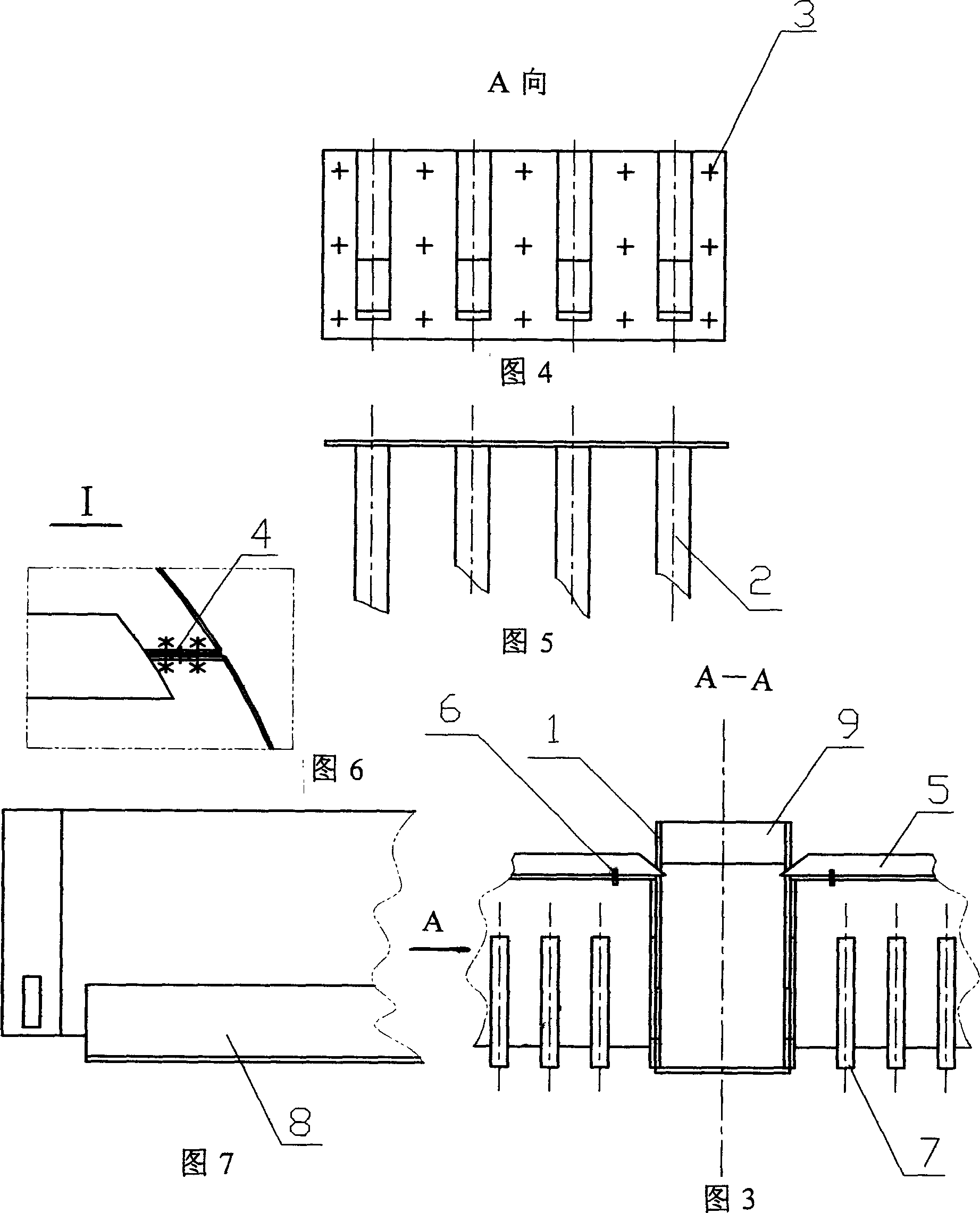

[0016] The present invention will be further described below in conjunction with the embodiments in the drawings:

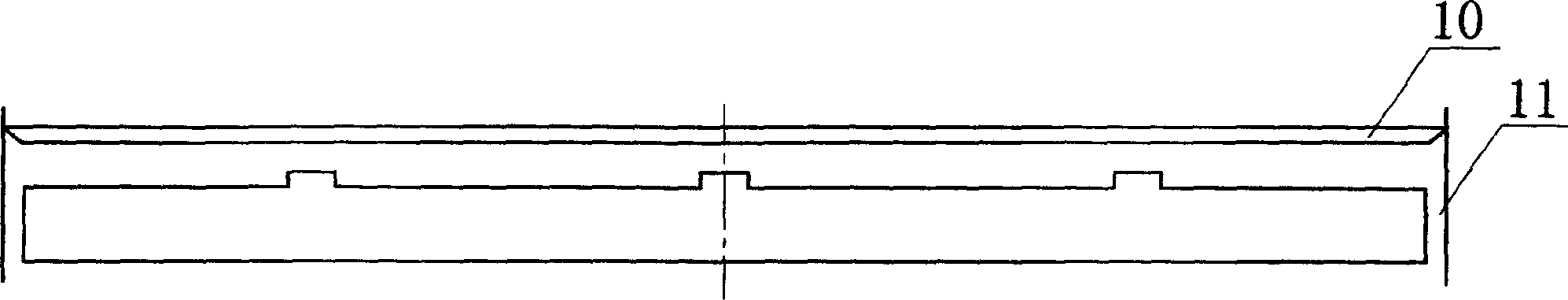

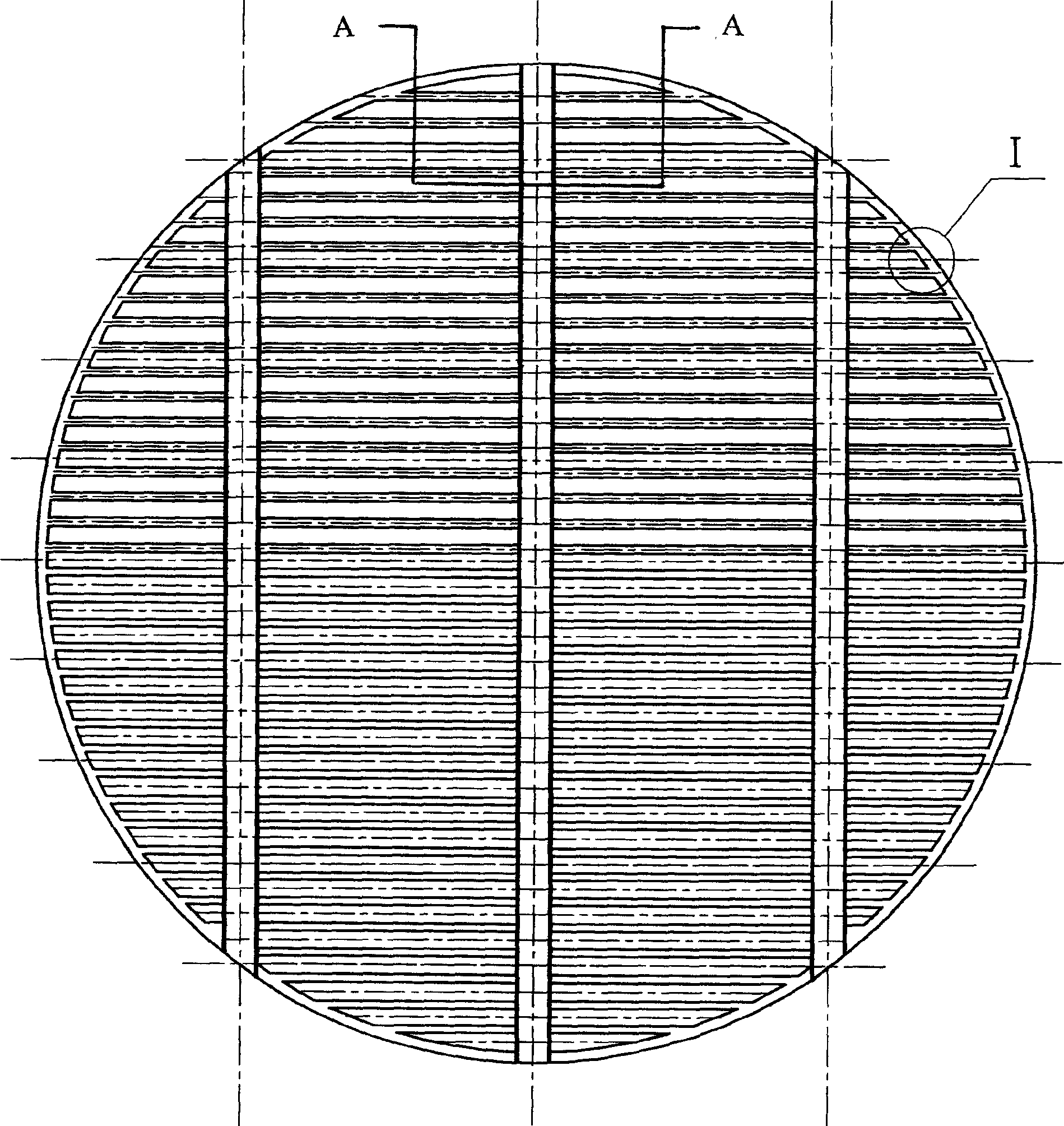

[0017] The present invention is mainly composed of beam liquid collection tank 1, liquid distribution tank 2, segmented connecting plate 3, connecting plate 4, liquid receiving angle steel 5, support bar 6, small angle steel 7, downcomer plate 8, reinforced ribs 9, and wall leakage prevention Ring 10, tower wall 11 and other components.

[0018] The present invention mainly adopts an anti-wall leakage ring 10 above the distributor and fixed on the tower wall 11. The number of girders arranged in the tower wall 11 can be determined according to the tower diameter. The girder is the liquid collection tank 1. The number of tanks can be set according to the tower diameter. The girder liquid collection tank 1 is used as the main body to separate the liquid distribution tank 2, and the liquid distribution tank 2 is connected into a single unit through the connecting plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com