Method for optimizing value of ethylene device

An optimization method and ethylene plant technology, applied in cracking, non-catalytic thermal cracking, petroleum industry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

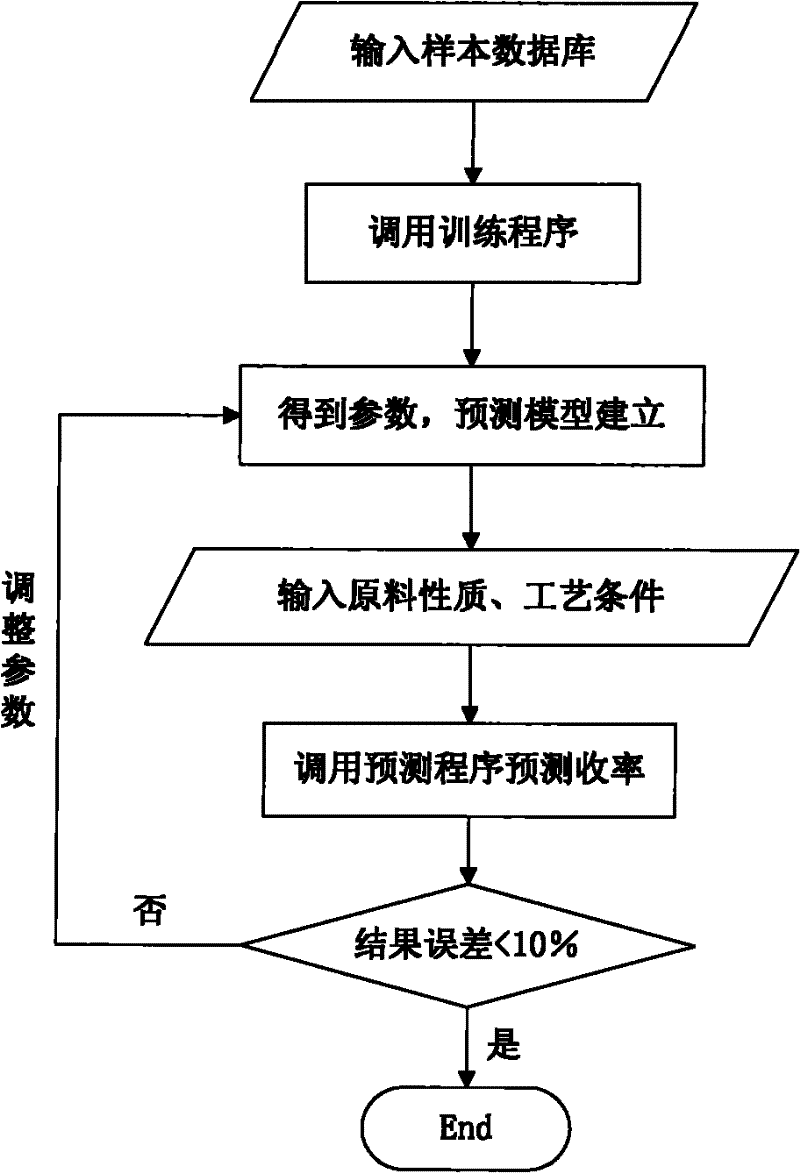

Method used

Image

Examples

Embodiment 1

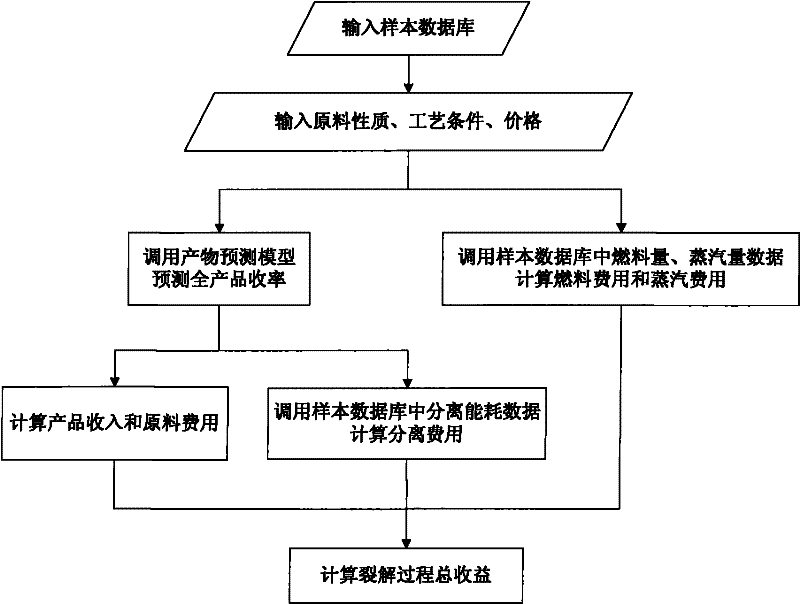

[0095] Taking the design scheme of 1 million tons of ethylene project as an example, adopting scheme 1, considering that the operating cost remains unchanged, let the total income = product sales income - raw material cost - fuel cost - separation cost + steam income, and calculate the maximum total income under the scheme The optimal operating conditions and the total income of the pyrolysis process.

[0096] Tianjin 1 million tons of ethylene design scheme adopted SL-I type cracking furnace (100,000 tons / year), sequential separation process, and selected two types of naphtha (1.112 million tons of naphtha 1# + 357,300 tons of naphtha 2#) and a hydrogenated tail oil (1.2234 million tons) as the main raw materials. The ethane and propane produced by cracking are recycled. During the calculation, the dry gas portion of the refinery is not considered.

[0097] First build the sample. The physical properties of the three cracking raw materials used in the ethylene design schem...

Embodiment 2

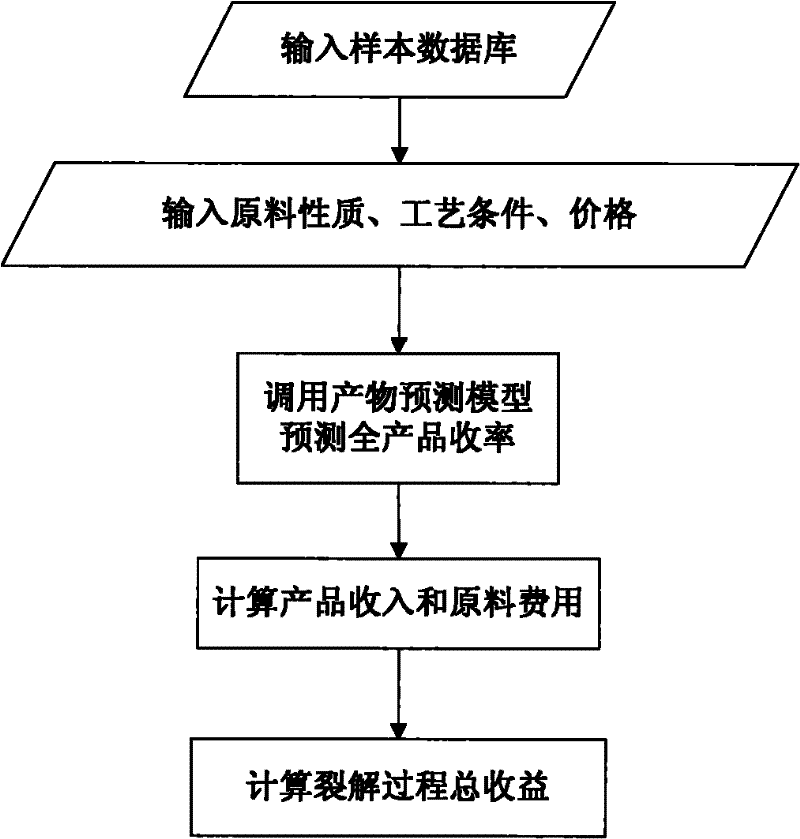

[0116] Taking the design scheme of the 1 million tons of ethylene project as an example, using scheme 2, let the total product income = ∑ (yield of various cracking products × corresponding product price) - raw material price, and calculate the maximum income under the scheme of maximum total product income Optimal operating conditions and the total income of the pyrolysis process.

[0117] First build the sample. The physical properties of the three cracking raw materials used in the ethylene design scheme are collected, and their physical properties are shown in Table 1; the cracking experiments of the three raw materials under different process conditions are respectively carried out in the cracking simulation experimental device, and the product yield is calculated; For the price system of ethylene feasibility study stage, see price 3 in price data table 5. The sample database is composed of the physical properties of cracking raw materials, thermal cracking process condi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com