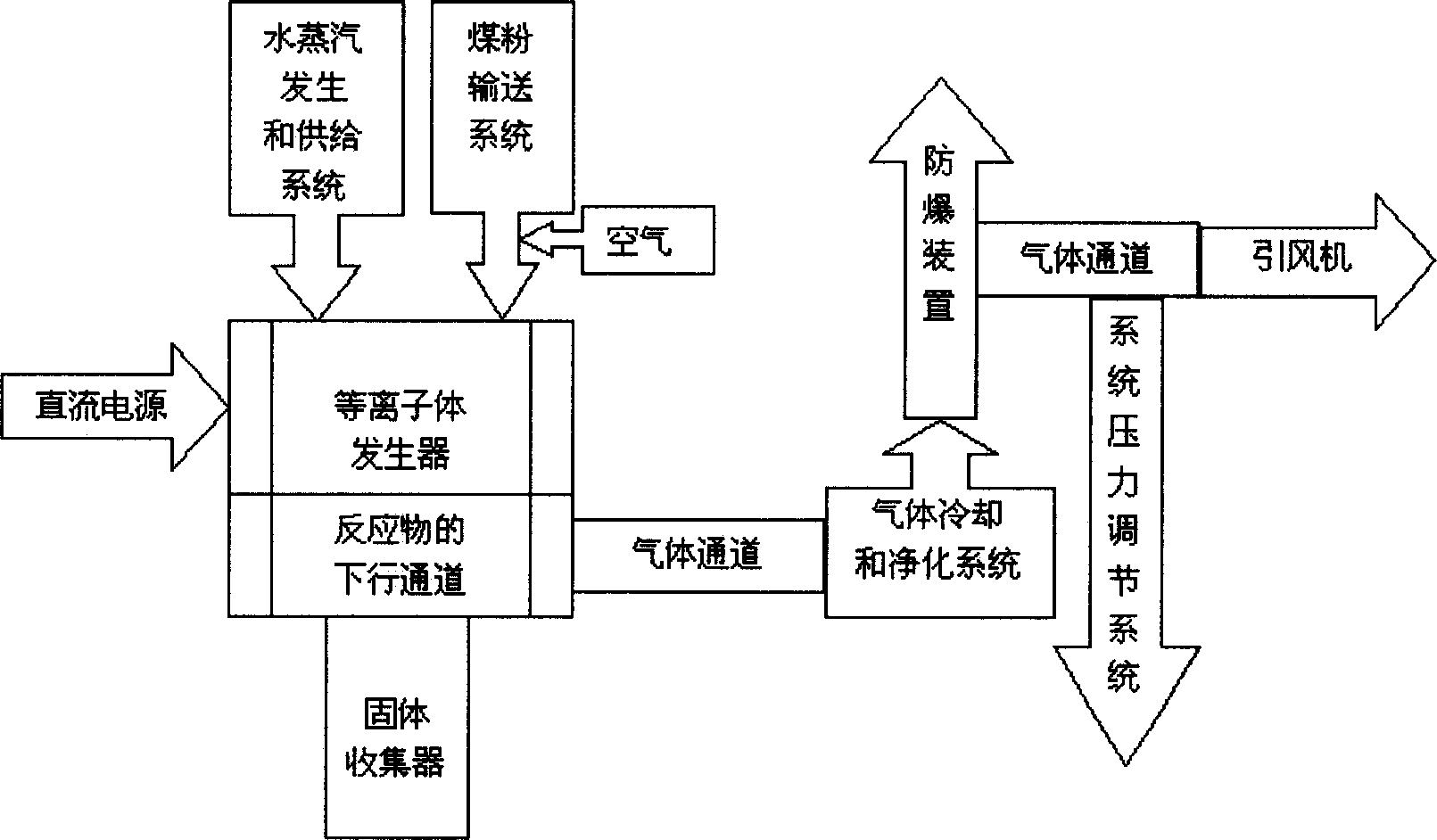

Method and apparatus for continuously preparing foam carbon material from coal

A technology of foamed carbon and pulverized coal, which is applied in the petroleum industry, coking ovens, indirect heating and dry distillation, etc., can solve the problems of expensive raw materials, process and complexity, and achieve the effects of reducing production costs, responding fully and quickly, and improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0030] Taiji coal is used as raw material, and the pulverized coal particle size is less than 2 mm. Set the pressure of the gas in the steam generator to 1.4 to 1.8 atmospheres, heat the water in the steam generator, and when the set pressure is reached, turn on the induced draft fan and adjust the pressure regulating system to make the system pressure negative 20 mm Water column, connected to circulating cooling water.

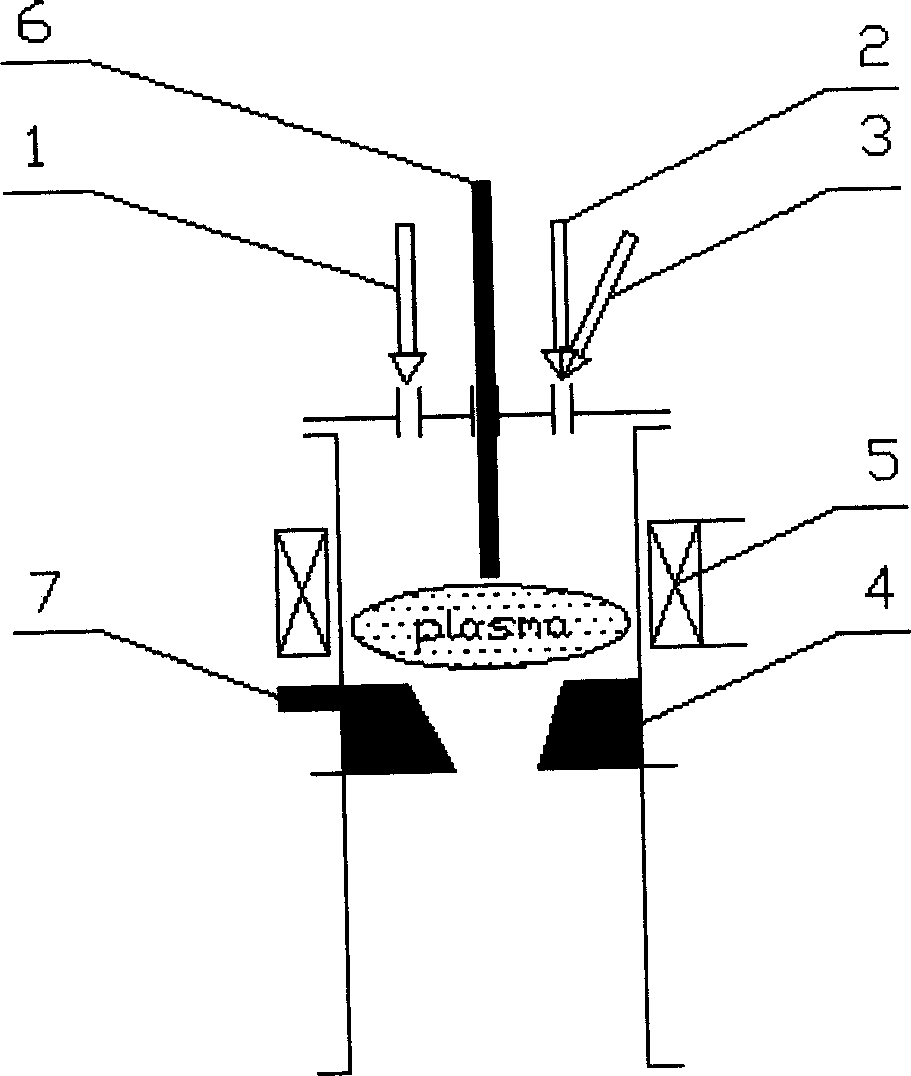

[0031] Connect the plasma working gas (compressed air), the flow rate of the compressed air is 1.2 cubic meters per hour; connect the electric current of the electromagnetic coil, the current is 245 amperes; connect the power supply and cause the electric arc of the plasma generator, the electric current of the electric arc is 260 amperes, the voltage of the arc at this time is 270 volts; the high-temperature water vapor in the steam delivery system is passed, and the flow rate of the water vapor is 2.4 kg / hour; 3.0 kg / h; in this way, the compressed air dire...

Embodiment approach 2

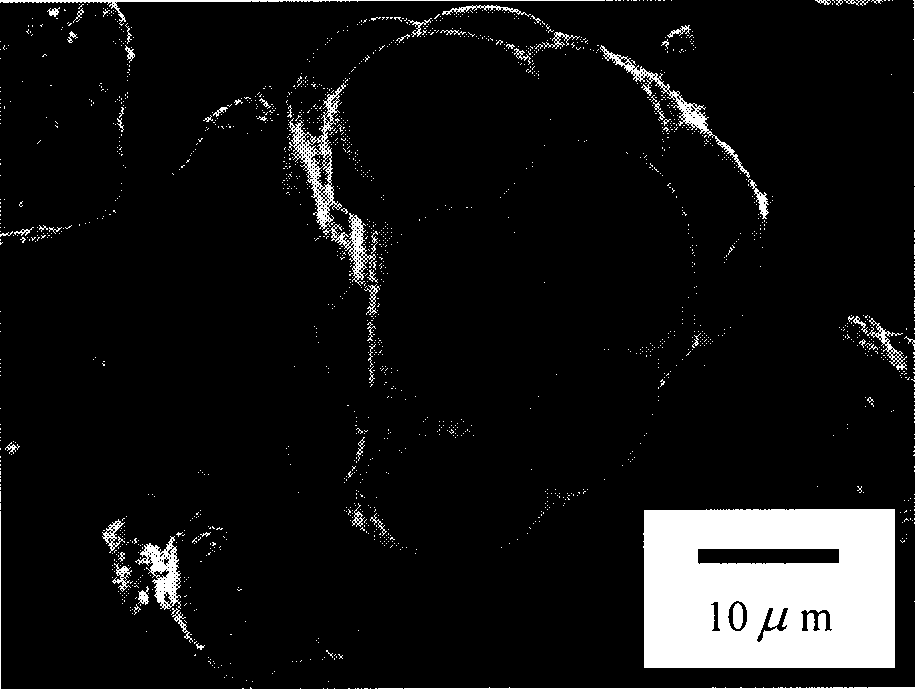

[0033] Others are the same as Embodiment 1, when the electric current of the electric arc is 290 amperes, the voltage of the electric arc is about 250 volts, and the delivery rate of pulverized coal is 2.1 kg / hour, the photo of the typical electron scanning electron microscope of the obtained foamed carbon material is shown in Figure 5 .

Embodiment approach 3

[0035] Others are the same as embodiment 1, when the delivery rate of pulverized coal is 1.6 kg / hour, the photo of the typical scanning electron microscope of the obtained foamed carbon material is shown in Figure 6 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com