Method and device for continuously feeding low-boiling point materials to high-pressure devices

A high-pressure device and low-boiling point technology, applied in the direction of using atmospheric pressure to chemically change substances, chemical instruments and methods, chemical/physical processes, etc., can solve the problem of easy generation of air bubbles at the feed pump, failure to feed normally, Easy to vaporize and other problems, to achieve the effect of reducing pump stop problems, ensuring continuity and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

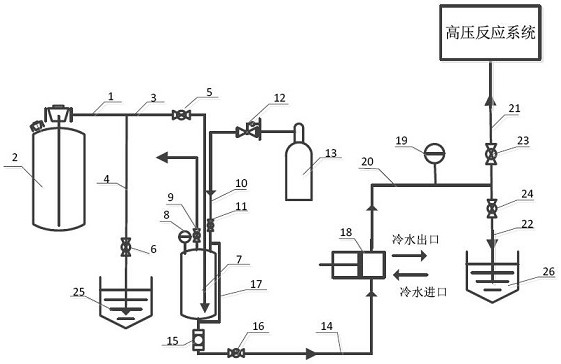

[0029] figure 1 The schematic diagram of the connection structure can be applied to the direct amination of isobutene to produce tert-butylamine synthesis reaction device (reaction system pressure is 5.0MPa) with low boiling point and easy vaporization material liquid ammonia (boiling point at normal pressure -33.5°C, saturated vapor pressure at normal temperature 0.922MPa (25 ℃)) feed.

[0030] The device includes the following components: low boiling point material storage tank (liquid ammonia storage tank) V-1, (liquid ammonia) pressure-resistant buffer tank V-2, protective gas (nitrogen) cylinder V-3, (liquid ammonia corrosion-resistant) inlet Material pump P-1, low-boiling point material (ammonia) absorption tank V-4, low-boiling point material (ammonia) absorption tank V-5, pressure-resistant (liquid ammonia corrosion-resistant) level gauge LA, corrosion-resistant ball valve HV1~ 7. Pressure reducing valve PCV-1, pressure gauge PI1~2;

[0031] The pipeline L1 is connec...

Embodiment 2

[0041] figure 1 The schematic diagram of the connection structure can be applied to the direct amination of isobutene to tert-butylamine synthesis reaction device (reaction system pressure is 5.0MPa) isobutene, a low-boiling and easy-to-vaporize material (boiling point at normal pressure -6.9°C, saturated vapor pressure at normal temperature 0.285MPa (25°C )) feed.

[0042] The device includes the following components: low boiling point material (isobutylene) storage tank V-1, (isobutylene) pressure buffer tank V-2, protective gas (nitrogen) cylinder V-3, (isobutylene corrosion resistant) feed pump P-1 , Low-boiling point material (isobutylene) absorption tank V-4, low-boiling point material (isobutylene) absorption tank V-5, pressure-resistant (isobutylene-resistant) liquid level gauge LA, corrosion-resistant ball valve HV1~7, pressure reducing valve PCV-1 , Pressure gauge PI1~2;

[0043] The pipeline L1 is connected to the bottom pipe of the isobutylene storage tank V-1, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com