Method for preparing isopropyl acetate through rectification

A technology of isopropyl acetate and methyl acetate, which is applied in the field of reaction and distillation of methyl acetate and isopropanol to produce isopropyl acetate, can solve problems such as difficult separation, difficult separation process, and shortened process, and achieve mild reaction conditions , Simplify the process flow, improve the effect of conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

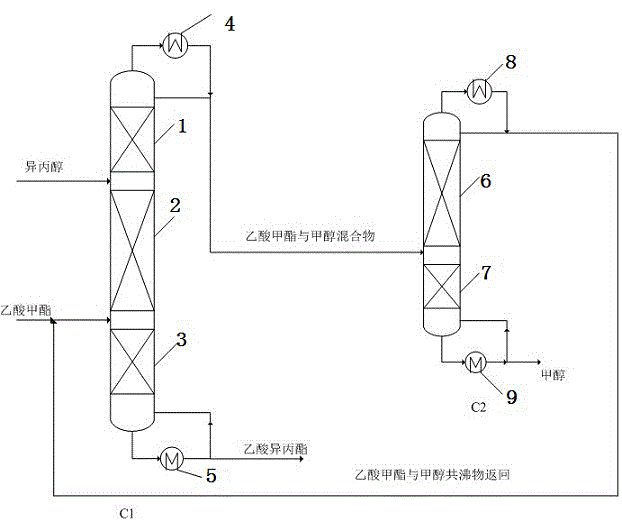

[0025] In a process device mainly composed of a reactive distillation tower and a methyl acetate recovery tower, isopropyl acetate is produced from raw material isopropanol and methyl acetate under the action of a cation exchange resin.

[0026] The reactive distillation tower is a tray tower with a diameter of 800 mm and a height of 30 meters, with 50 trays inside; 9 trays in the rectification section, 36 trays in the reaction section, and 5 trays in the stripping section; the methyl acetate recovery tower is A packed tower with a diameter of 500mm and a height of 8 meters is equipped with structured packing and has 25 theoretical plates; among them, there are 10 plates in the rectification section and 15 plates in the stripping section. The two towers are operated under normal pressure.

[0027] The operating conditions of the reactive distillation column:

[0028] The raw material isopropanol enters the upper part of the reaction section 2 of the reactive distillation ...

Embodiment 2

[0032] In a process device mainly composed of a reactive distillation tower and a methyl acetate recovery tower, isopropyl acetate is produced from raw material isopropanol and methyl acetate under the action of a cation exchange resin.

[0033] The reactive distillation tower is a packed tower with a diameter of 800 mm and a height of 30 meters, with 25 meters of structured packing inside and 70 theoretical plates; among them, there are 19 plates in the rectification section, 41 plates in the reaction section, and 10 plates in the stripping section; The methyl ester recovery tower is a packed tower with a diameter of 500mm and a height of 8 meters, with structured packing inside, and the number of theoretical plates is 25

[0034] ; Among them, there are 10 rectifying sections and 15 stripping sections, and the two towers are operated under normal pressure.

[0035] The operating conditions of the reactive distillation column:

[0036] The raw material isopropanol enters...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com