High-efficiency enhanced multi-scale mixed mass transfer device and method

A multi-scale and high-efficiency technology, applied in chemical instruments and methods, mixers, transportation and packaging, etc., can solve the problems of difficult power source, difficult control, poor reproducibility, etc., and achieve enhanced mass transfer and multi-scale mixing. Process, broad application prospects, easy to enlarge effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

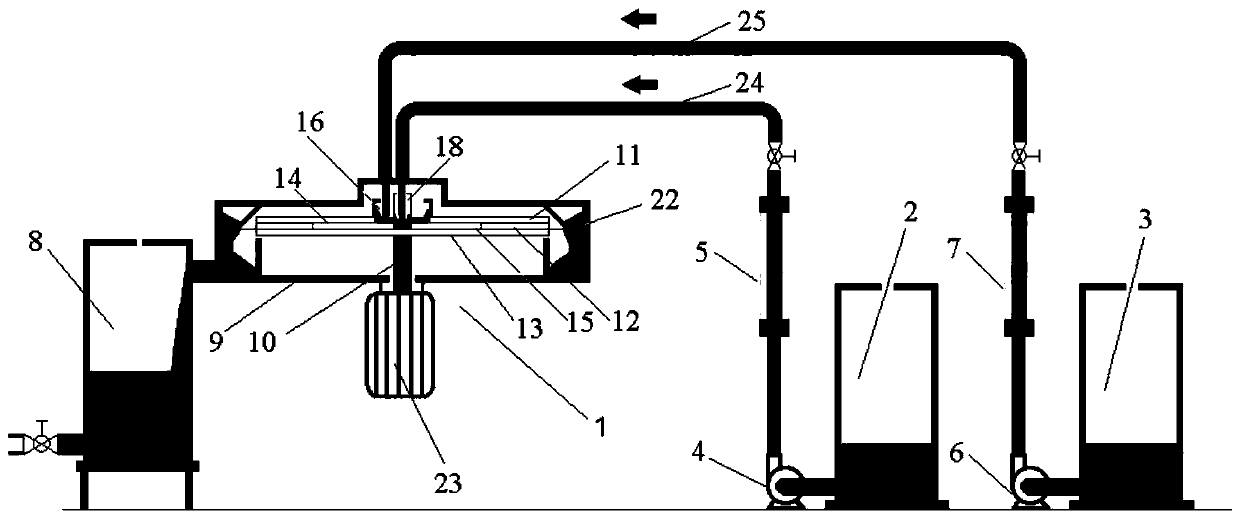

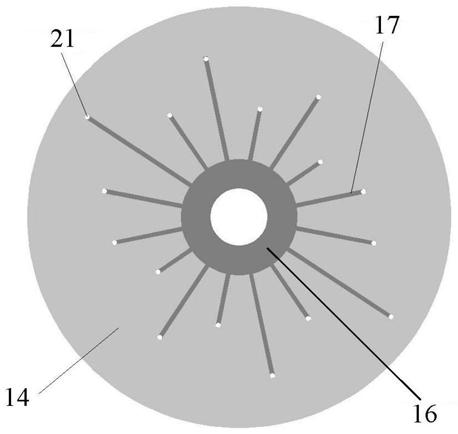

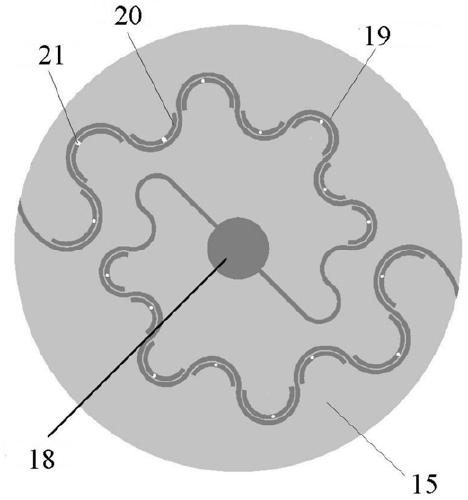

[0031] Such as figure 1 As shown, a high-efficiency enhanced multi-scale mixed mass transfer device includes a high-gravity fast reactor 1, a first feed-liquid storage tank 2 and a second feed-liquid storage tank 3, and the first feed-liquid storage tank passes through a first centrifugal pump 4 The first flowmeter 5 is communicated with the inlet one 18 of the supergravity fast reactor; the second material liquid storage tank is communicated with the inlet two 16 of the supergravity fast reactor by the second centrifugal pump 6 and the second flowmeter 7; The outlet of the high-gravity fast reactor is provided with a metering tank 8; the high-gravity fast reactor includes a stator 9 and a rotor 10 with a diameter of 280mm; the rotor is composed of three pinches tightly stacked, and the first pinch is sequentially from top to bottom 11. The second pinch plate 12 and the third pinch plate 13, the contact surface of the first pinch plate and the second pinch plate is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com