Preparation method and apparatus for amorphous nano carbon tube

A technology for carbon nanotubes and preparation devices, which is applied in the fields of nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve the problems of high requirements on device sealing, difficult continuous production, and high raw material cost, and achieves easy operation, increased output, and improved equipment. well-structured effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

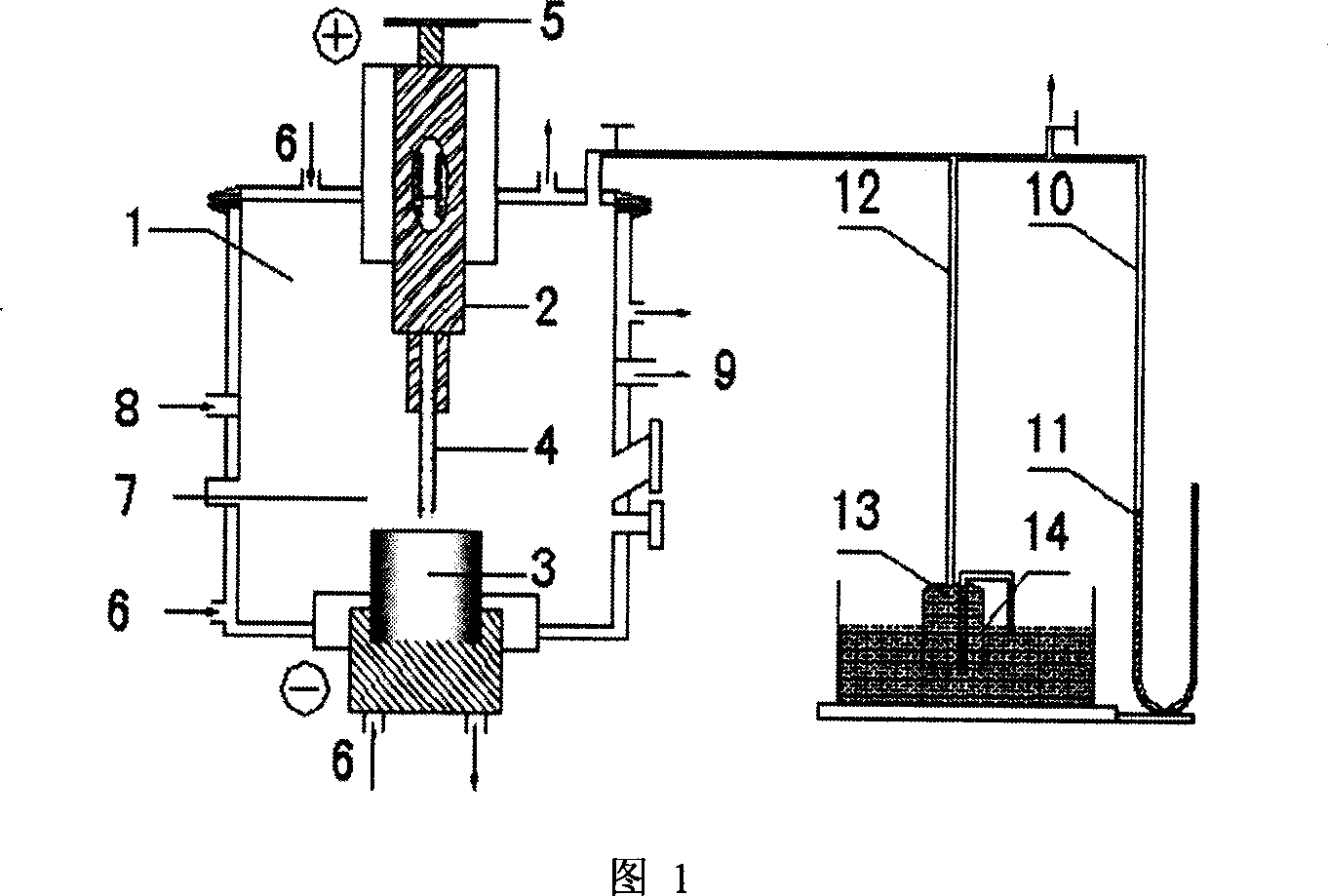

Method used

Image

Examples

Embodiment 1

[0021] (1) Mix the waste coke powder, tar and nickel powder according to the mass ratio of 68.2:24.5:7.3. After the mixture is extruded into a coke rod with an outer diameter of 1.00cm on the screw feeder, the coke rod is placed in a tube furnace Under the protection of nitrogen, the temperature was programmed to 900 °C, and carbonized at this temperature for 4 hours to obtain a carbon rod with a certain electrical conductivity. The outer diameter of the carbon rod was 0.95 cm and the length was 15 cm.

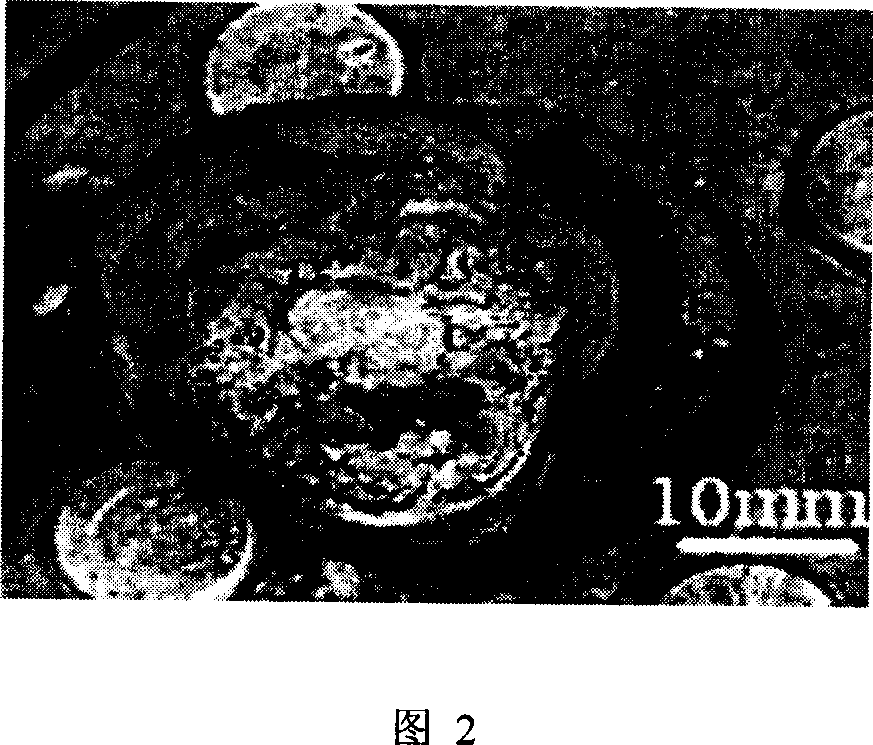

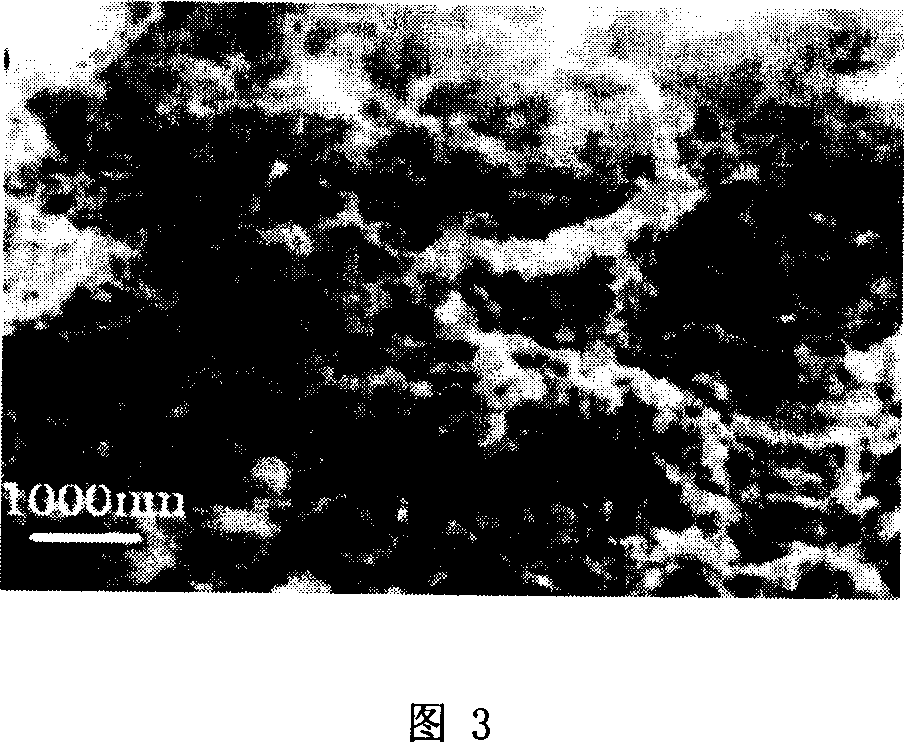

[0022] (2) the carbon stick that makes with step (1) is anode, and high-purity graphite stick is cathode, in the mixed atmosphere that the volume ratio of helium (purity is 99.5%) and acetylene (purity is 98.5%) is 4: 1 In the process, the carbon nanotube material was prepared by arc discharge under normal pressure ((0.1±0.0005) MPa). The arc discharge stopped after 15 minutes, and the solid phase product containing amorphous carbon nanotubes was mainly formed at the cathode. I...

Embodiment 2

[0027] (1) With the step (1) of embodiment 1.

[0028] (2) the carbon stick that makes with step (1) is anode, and high-purity graphite stick is cathode, in the mixed atmosphere that the volume ratio of nitrogen (purity is 99.5%) and acetylene (purity is 98.5%) is 4: 1 , carbon nanotube materials were prepared by arc discharge under normal pressure ((0.1 ± 0.0005) MPa), the arc discharge stopped after 15 minutes, and the solid phase products containing amorphous carbon nanotubes were mainly formed at the cathode, and the cathode products in this atmosphere could be Up to 6.5g. The scanning electron micrograph of the product is similar to Example 1.

Embodiment 3

[0030] (1) With the step (1) of embodiment 1.

[0031] (2) the carbon rod that step (1) makes is anode, and high-purity graphite rod is negative electrode, in the volume ratio of nitrogen (purity is 99.5%) and acetylene (purity is 98.5%) and carbon dioxide (purity is 98.5%) In a mixed atmosphere of 80:15:5, carbon nanotube materials were prepared by arc discharge under normal pressure ((0.1±0.0005) MPa), and the arc discharge stopped after 15 minutes, and the solid-phase products containing amorphous carbon nanotubes were mainly in The cathode is formed, and the cathode product can reach 4.5g in this atmosphere. The scanning electron micrograph of the product is similar to Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com