Miniature reaction device based on hollow foam material and application thereof

A micro-reaction, foam material technology, applied in chemical/physical/physical-chemical processes, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as low effective reaction area, low mass transfer efficiency, and complex preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

application specific Embodiment approach

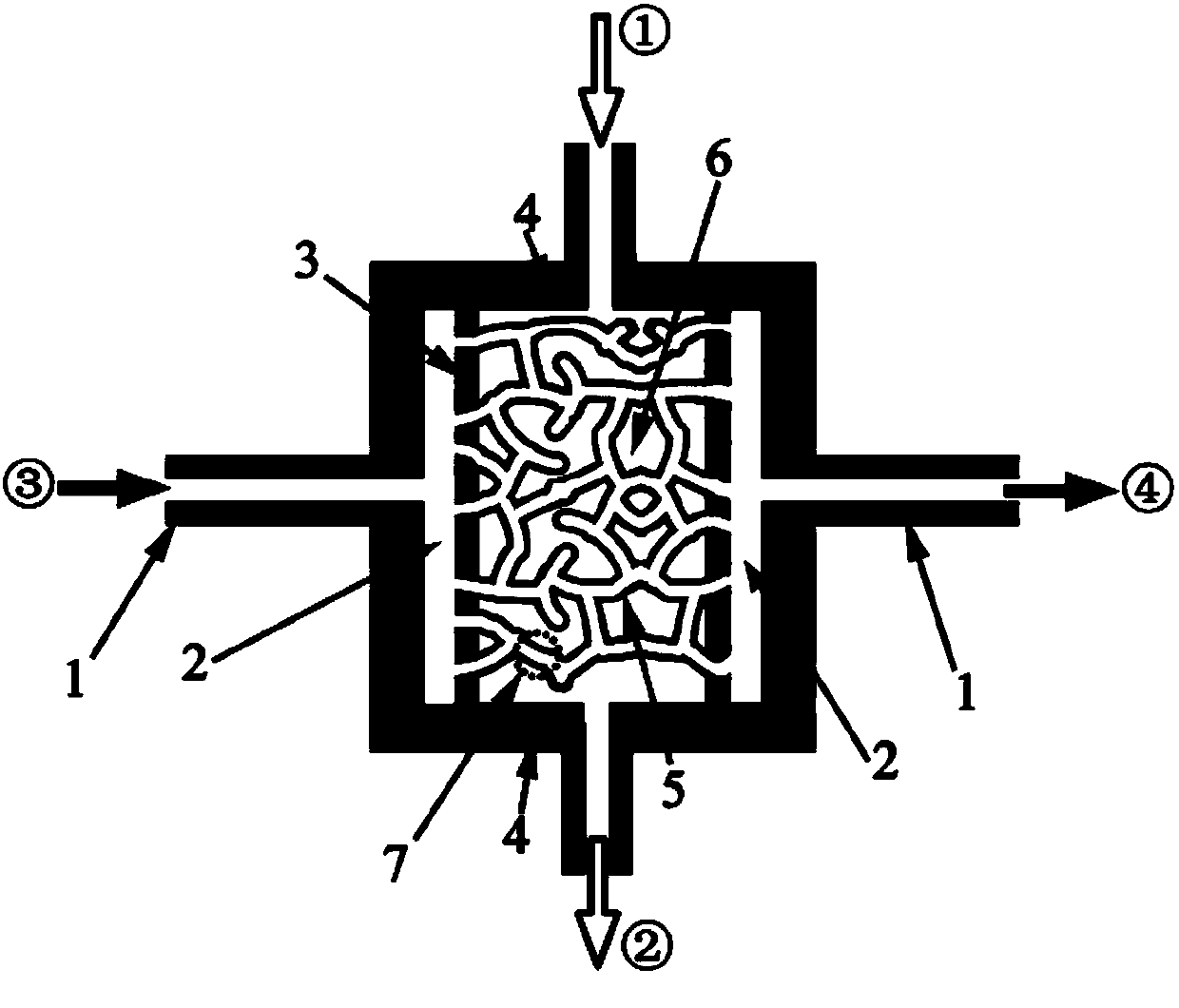

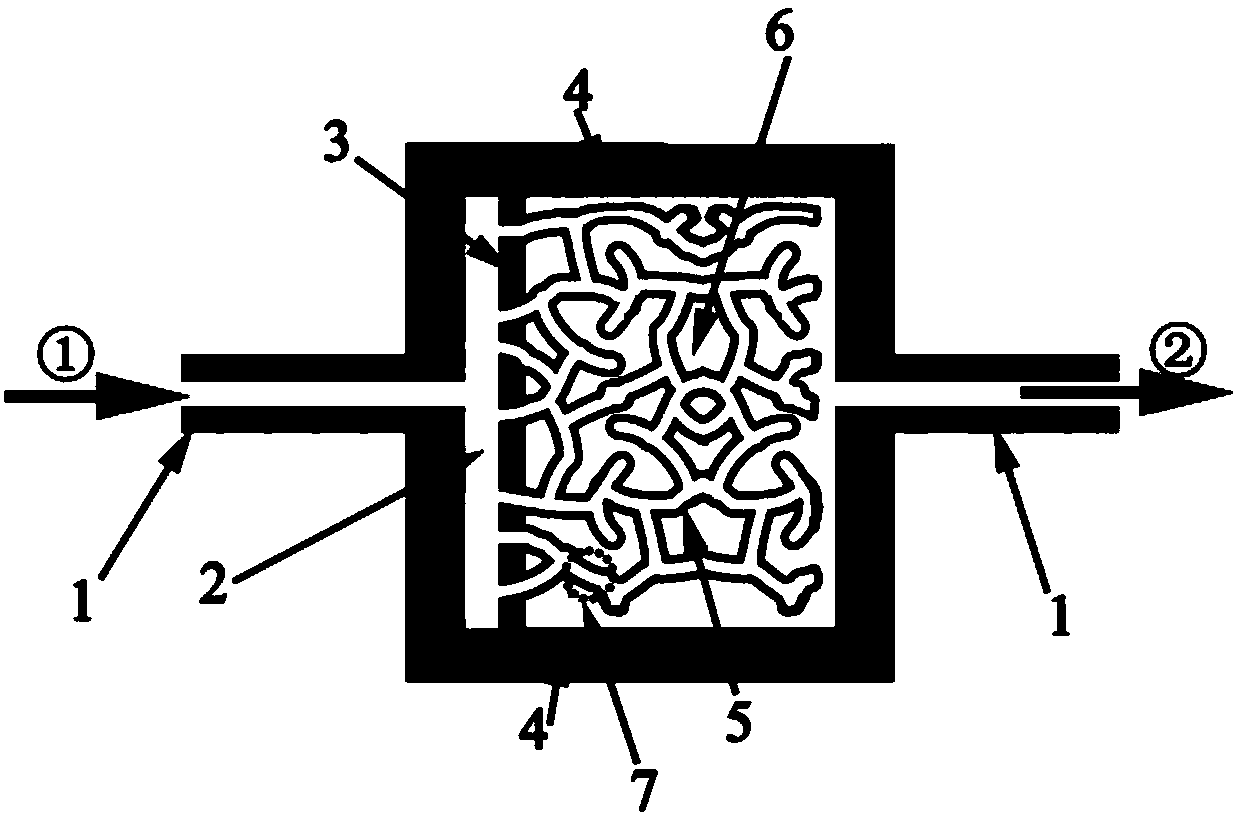

[0088] In the specific implementation of the micro-reaction device based on hollow foam material and its application, the present invention uses hollow foam material with different physical / chemical structures and different materials as the material for the main functional area of the reaction. Interface, collecting cavity, fluid-tight barrier layer, hollow foam material microchannel wall reaction zone, design the micro reaction unit assembly of the micro reaction device based on hollow foam material according to the present invention, and enumerate the corresponding application specific implementation methods as follows:

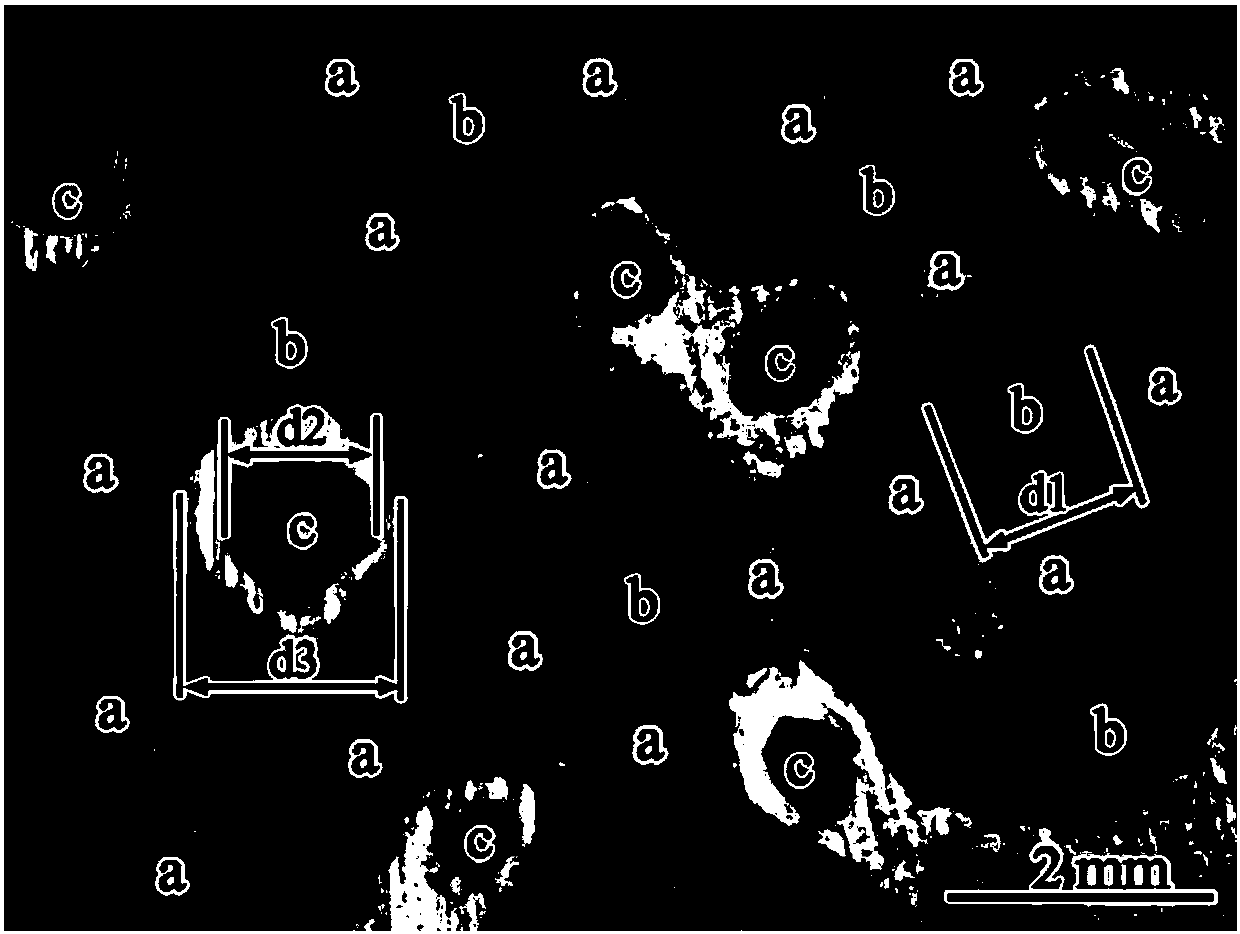

[0089] Such as figure 1 As shown, it can be seen from the macroscopic appearance that the micro-reaction device uses hollow foam material as the main functional area of the micro-reaction device. ) are connected in three dimensions to form a network structure of openings (b); wherein, the supporting skeleton (a) itself has a size-controllable, hollow mic...

Embodiment 1

[0124] This embodiment adopts the structural design of cylindrical micro-reaction unit components, see the attached Figure 19 . The main react ribbon consists of such as Figure 4 The shown physical structure or chemical structure is composed of hollow foam material with isotropic hollow microchannel pipe wall, and the macroscopic dimension of the hollow foam material cylinder is φ200mm, and the height is 500mm. Wherein, a is the inner cavity of the hollow microchannel; b is the inner wall surface of the hollow microchannel tube wall with a dense structure; c is the outer wall surface of the hollow microchannel tube wall with a dense structure. The wall body of the hollow microchannel is made of stainless steel, the outer diameter of the hollow microchannel is 2mm, and the inner diameter is 1mm. The micro reaction device composed of the reaction unit components is used for the preparation of glyoxylic acid, the fluid phase ① is a mixed solution, the solvent is tert-butanol,...

Embodiment 2

[0126] This embodiment adopts the structural design of cylindrical micro-reaction unit components, see the attached Figure 20 . The main reaction functional area is made of a hollow foam material, and the structure of the hollow microchannel tube wall of the hollow foam material is as follows: Figure 5 shown. The macroscopic dimensions of the hollow foam cylinder are φ300mm and 600mm high. Wherein, a is the inner cavity of the hollow microchannel; b is the inner wall surface of the hollow microchannel tube wall with a dense structure; c is the outer wall surface of the dense structure hollow microchannel tube wall through in-situ generation of catalytic active centers. The wall body of the hollow microchannel is made of pure silicon carbide, and the surface of the outer wall is prepared by ZSM-5 molecular sieve catalytic coating through in-situ hydrothermal synthesis reaction. The hollow microchannel has an outer diameter of 3 mm and an inner diameter of 1.5 mm. The micr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter size | aaaaa | aaaaa |

| Inner diameter size | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com