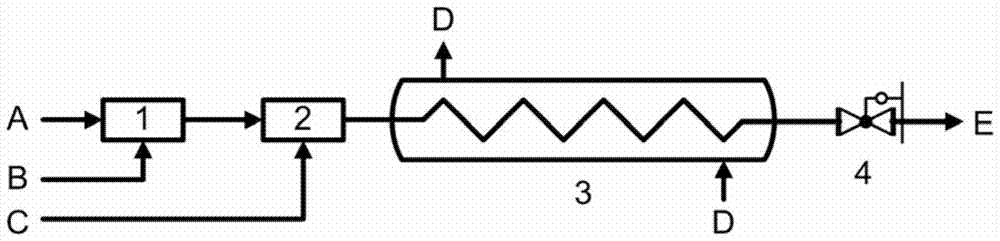

A system and method for synthesizing cyclohexanone oxime in a microreactor

A technology of cyclohexanone oxime and micro-reactor, which is applied in oxime preparation, organic chemistry, etc., can solve the problems of large material retention, local hot spots, poor effect, etc., and achieve improved controllability and safety, and material retention small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Equipment parameters: the first micro-mixer 1 is a micro-mesh mixer, and the second micro-mixer 2 is a T-shaped micro-channel mixer. Among them, the micro-sieve mixer contains 20 micro-sieves with a diameter of 0.05 mm, and the hydraulic diameter of the T-shaped micro-channel is 0.1 mm.

[0027] Operating conditions: the concentration of titanium silicon molecular sieve in raw material A is 0.1wt%, the concentration of ammonia is 1wt%, and the molar ratio of ammonia to cyclohexanone is 2.5. The concentration of hydrogen peroxide in raw material B is 1 wt%, and the molar ratio of hydrogen peroxide to cyclohexanone is 1. The reaction temperature is 90° C., the reaction pressure is 0.2 MPa, and the reaction residence time is 20 minutes.

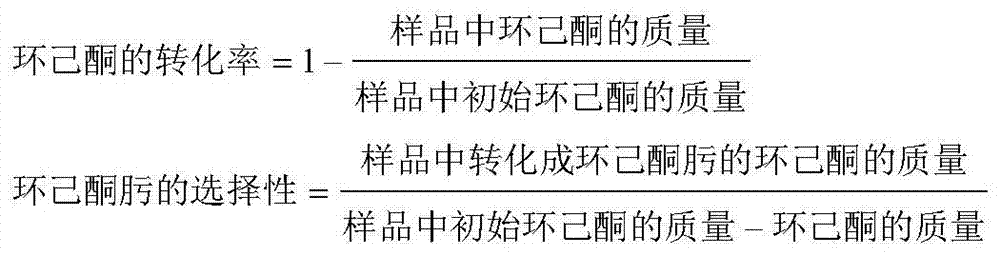

[0028] Reaction result: the conversion rate of cyclohexanone is 98.2%, and the selectivity of cyclohexanone oxime is 99.8%.

Embodiment 2

[0030] Equipment parameters: the first micro-mixer 1 is a micro-mesh mixer, and the second micro-mixer 2 is a Y-shaped micro-channel mixer. Among them, the micro-sieve mixer contains a micro-sieve with a diameter of 5mm, and the hydraulic diameter of the Y-shaped microchannel is 6mm.

[0031] Operating conditions: the concentration of titanium silicon molecular sieve in raw material A is 10wt%, the concentration of ammonia is 15wt%, and the molar ratio of ammonia and cyclohexanone is 1.5. The concentration of hydrogen peroxide in raw material B is 10wt%, and the molar ratio of hydrogen peroxide to cyclohexanone is 1.5. The reaction temperature is 60° C., the reaction pressure is 0.5 MPa, and the reaction residence time is 3 minutes.

[0032] Reaction result: the conversion rate of cyclohexanone is 99.8%, and the selectivity of cyclohexanone oxime is 99.0%.

Embodiment 3

[0034] Equipment parameters: the first micro-mixer 1 is a micro-mesh mixer, and the second micro-mixer 2 is a cross-shaped micro-channel mixer. Wherein, the micro-sieve mixer contains two micro-sieves with a diameter of 4mm, and the hydraulic diameter of the cross-shaped microchannel is 4mm.

[0035] Operating conditions: the concentration of titanium silicon molecular sieve in raw material A is 8wt%, the concentration of ammonia is 12wt%, and the molar ratio of ammonia and cyclohexanone is 2. The concentration of hydrogen peroxide in raw material B is 8wt%, and the molar ratio of hydrogen peroxide to cyclohexanone is 1.5. The reaction temperature is 70° C., the reaction pressure is 0.4 MPa, and the reaction residence time is 5 min.

[0036] Reaction result: the conversion rate of cyclohexanone is 99.6%, and the selectivity of cyclohexanone oxime is 99.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com