Underground heat insulation air-suspended bed reactor

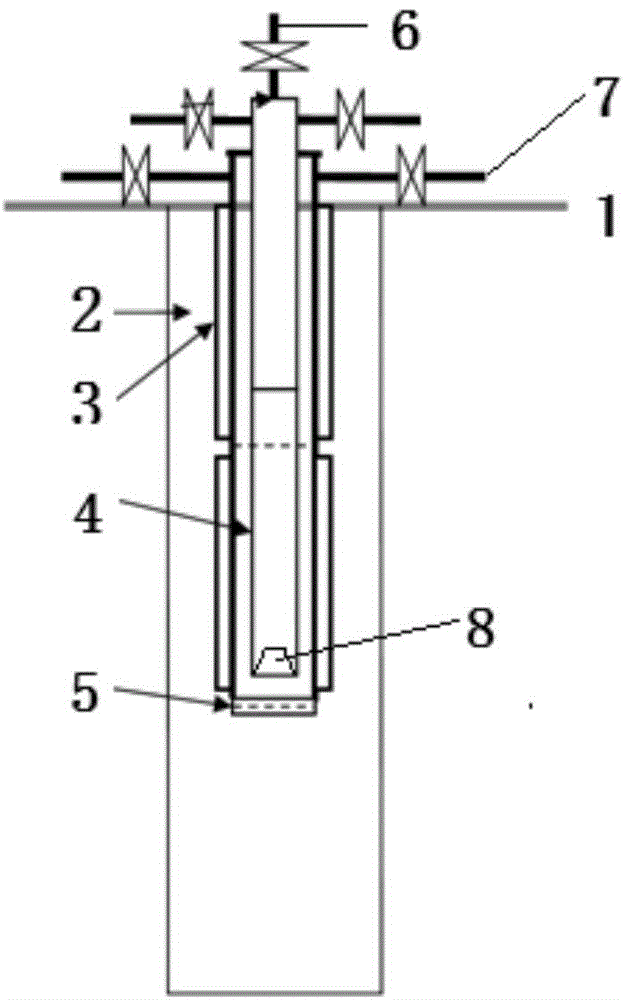

A reactor and suspended bed technology, which is applied in the field of downhole thermal insulation and emptying suspended bed reactors, can solve the problems of heavy tonnage, high manufacturing difficulty, large wall thickness of the reactor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

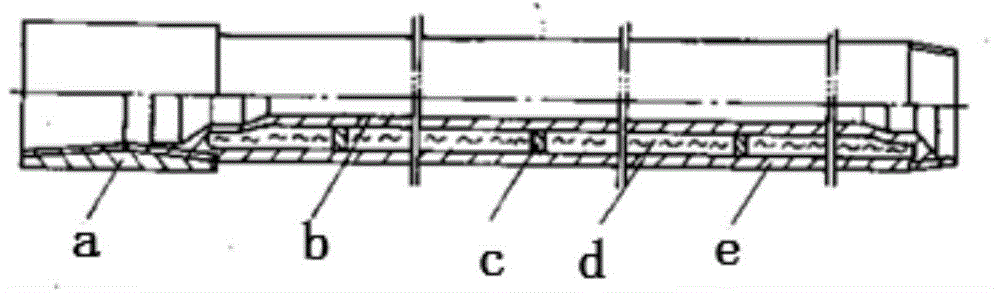

[0085] Utilizing the downhole thermally insulated and empty suspended bed reactor of the present invention, the hydrogenation and light chemical industrial test of 1.5t / d heavy raw material catalytic oil slurry is verified, wherein the downhole thermally insulated and empty for the preparation of catalytic fluid The structural characteristics of the suspended bed reactor, the downhole insulated and empty suspension bed reactor for the preparation of catalytic oil slurry, and the downhole insulated and empty suspension bed reactor for the hydrogenation of catalytic oil slurry are shown in Table 1.

[0086] Table 1. Structural features of downhole thermally insulated and empty suspended bed reactor

[0087]

[0088]

[0089] In the implementation example of the present invention, it is verified by the hydrogenation light chemical industry test of 1.5t / d heavy raw material catalytic oil slurry, wherein, the starting solvent is the prepared mixed solvent and circulating solve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com