Low-energy preparation method of positive electricity nanometer emulsion

A nano-emulsion, positive charge technology, applied in mixing methods, chemical instruments and methods, dissolution and other directions, can solve the problems of high cost, high energy consumption, easy to contaminate preparations, etc., and achieve the effects of energy saving, easy realization and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

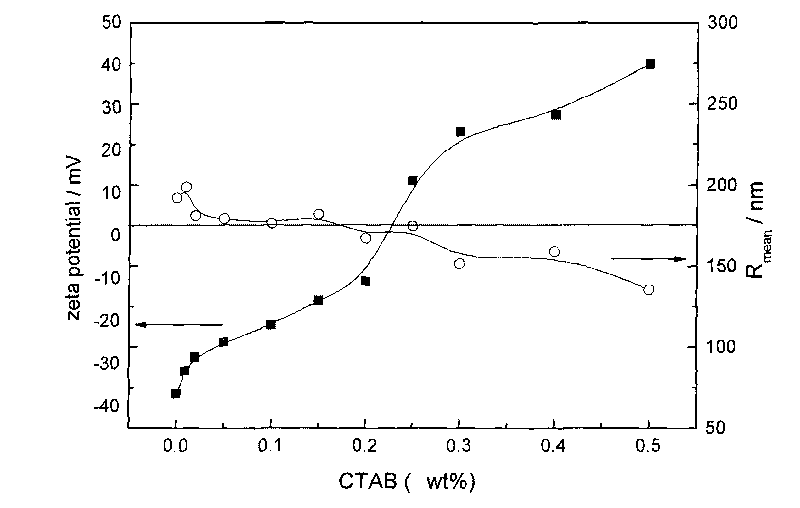

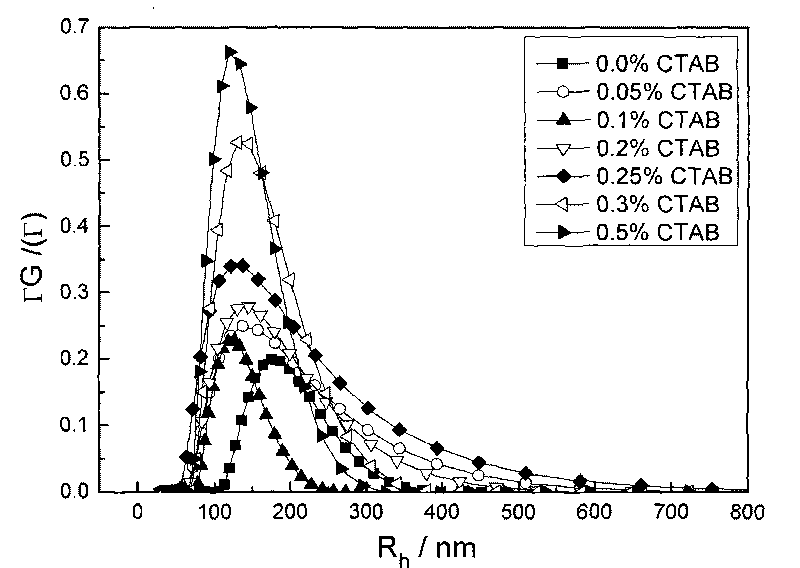

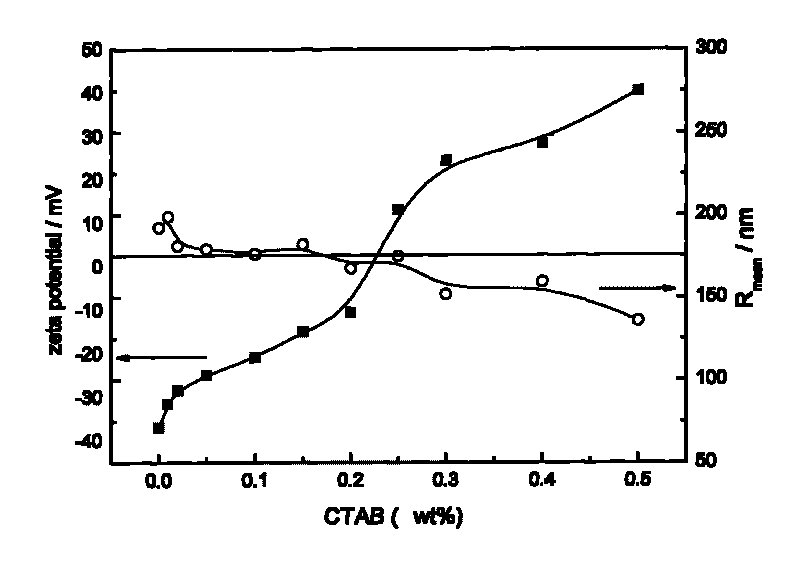

[0023] Positively charged paraffin nanoemulsion, with an average particle size of 100-250nm and a zeta potential of +15-+35mV, based on 100 parts by weight (unit: gram), the components are as follows:

[0024] 30 parts of liquid paraffin, 3.3 parts of nonionic surfactant Tween60, 2.7 parts of nonionic surfactant Span60, 0.4 part of cationic surfactant cetyltrimethylammonium bromide, 2 parts of NaBr, 61.6 parts of water share.

[0025] Preparation:

[0026] 0.4 parts of cationic surfactant cetyltrimethylammonium bromide and 2 parts of NaBr are dissolved in 61.6 parts of water to obtain the water phase, and then 30 parts of the oil phase are mixed with 3.3 parts of nonionic surfactant Tween60 and 2.7 parts of Span60 Put it together with the water phase in the reactor and mix evenly, then stir and emulsify at 150rpm at 75°C for 40min; place the reactor in an ice-water bath and quickly cool down to room temperature to obtain a positively charged nanoemulsion.

[0027] The positi...

Embodiment 2

[0039] Method is as described in Example 1, the difference is:

[0040] The emulsification temperature is 77°C, the average particle size of the positively charged nanoemulsion is 150-350nm, and the zeta potential is +15-+40mV. Based on 100 parts by weight (unit: gram), the components are as follows:

[0041] 40 parts of n-hexadecane, 4.5 parts of non-ionic surfactant Tween605.5 parts, Span605.5 parts, 0.3 parts of cationic Gemini surfactant 12-2-12, 1.5 parts of NaCl, 49 parts of water.

[0042] The experimental data on stability are as follows:

[0043] Lotion Appearance

Embodiment 3

[0045] Method is as described in embodiment 1 or 2, the difference is:

[0046] The emulsification temperature is 78°C, the average particle size of the positively charged paraffin nanoemulsion is 100-280nm, and the zeta potential is +5-+25mV. The components are as follows, all in parts by weight (unit: gram), and the total amount is 100 parts:

[0047] 40 parts of n-tetradecane, 4.5 parts of nonionic surfactant Tween60, 5.5 parts of Span60, 0.2 part of cationic surfactant octadecylamine, Na 2 SO 4 0.5 parts, 49.3 parts of water.

[0048] The experimental data on stability are as follows:

[0049] Lotion Appearance

[0050] Lotion Appearance

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com