Ceramic tile adhesive

A technology of tile adhesive and auxiliary agent, applied in the field of tile adhesive, can solve the problems of wasting raw materials, polluting the environment, affecting construction speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] First, take by weight 35% inorganic gelling agent, 5% negative ion additive, 10% inorganic filler, 47% sand and 3% dry powder mortar additive, plus a certain proportion of water.

[0048] Among them, the inorganic gelling material is Portland cement, the negative ion additive is tourmaline, the inorganic filler is quartz powder with a fineness of 150 mesh, the sand is washed sand with a fineness of 40-70 mesh and washed sand with a fineness of 70-140 mesh mixture;

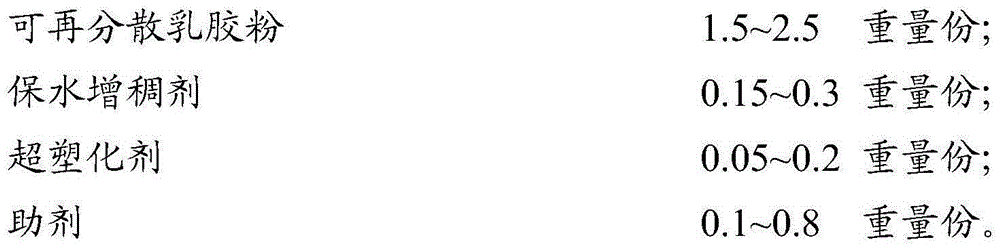

[0049] The composition of the dry powder mortar additive includes: redispersible latex powder, water-retaining thickener, superplasticizer and auxiliary agent, and the mass percentages of the above-mentioned components in the adhesive are: 2% redispersible latex powder, 0.2% water-retaining thickener, 0.05% superplasticizer and 0.75% additives. Among them, the redispersible latex powder is a copolymer of vinyl acetate and ethylene, the superplasticizer is a mixture of polycarboxylate and melamine, the thixo...

Embodiment 2

[0053] First, take by weight 30% inorganic gelling agent, 10% negative ion additive, 5% inorganic filler, 51% sand and 4% dry powder mortar additive, plus a certain proportion of water.

[0054] Among them, the inorganic gelling material is sulfoaluminate cement, the negative ion additive is a mixture of tourmaline and opal with a mass ratio of 1:1, the inorganic filler is fly ash with a fineness of 200 mesh, and the sand is a fineness of 40-70 mesh. A mixture of purpose quartz sand and quartz sand with a fineness of 70 to 140 mesh;

[0055] The composition of the dry powder mortar additive includes: redispersible latex powder, water-retaining thickener, superplasticizer and auxiliary agent, and the mass percentages of the above-mentioned components in the adhesive are respectively: 3.6% of redispersible latex powder, 0.15% water-retaining thickener, 0.1% superplasticizer and 0.15% additives. Among them, the redispersible latex powder is acrylate copolymer, the superplasticizer...

Embodiment 3

[0059] First, take by weight 40% inorganic gelling agent, 8% negative ion additive, 8% inorganic filler, 42% sand and 2% dry mortar additive, plus a certain proportion of water.

[0060] Among them, the inorganic gelling material is a mixture of Portland cement and sulphoaluminate cement, the negative ion additive is a mixture of opal and coral fossils with a mass ratio of 1:1, the inorganic filler is ground calcium carbonate, and the sand is a fineness of A mixture of 40-70 mesh quartz sand and 70-140 mesh quartz sand;

[0061] The composition of the dry powder mortar additive includes: redispersible latex powder, water-retaining thickener, superplasticizer and auxiliary agent, and the mass percentages of the above-mentioned components in the adhesive are: 1% redispersible latex powder, 0.25% water retention thickener, 0.2% superplasticizer and 0.555% additives. Among them, the redispersible latex powder is styrene and acrylate copolymer, the superplasticizer is melamine, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com