Novel Beckmann rearrangement method for preparing caprolactam from cyclohexanone oxime

A technology of Beckmann rearrangement and cyclohexanone oxime, which is applied to the preparation of lactam, chemical instruments and methods, chemical/physical/physicochemical processes, etc., can solve the problem of poor safety and reliability of reactors and reaction processes, Beckman Mann rearrangement reaction has a large amount of heat and the temperature is not easy to control, so as to achieve the effect of improving controllability and safety, reducing material retention and reducing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A novel Beckmann rearrangement method for preparing caprolactam by cyclohexanone oxime, as follows:

[0024] (1) Using a microreactor, using SO 3 The fuming sulfuric acid with a content of 20wt.% was used as the dispersed phase, the cyclohexanone oxime n-octane solution with a mass fraction of 10% was used as the continuous phase, the flow rate of the dispersed phase was 0.8mL / min, the flow rate of the continuous phase was 25mL / min, and the two In the microreactor, it is rapidly mixed and the Beckmann rearrangement reaction is initiated, the acid oxime ratio of the reaction is 1.06, and the temperature of the reaction system is 70 °C;

[0025] (2) the residence time of the mixed reaction material in the delay pipeline connected with the outlet of the microreactor is 40s, and it is matured to complete the reaction;

[0026] (3) The ripening product is passed into another microreactor as a continuous phase, mixed with the water passed in as a dispersed phase, and a hydro...

Embodiment 2

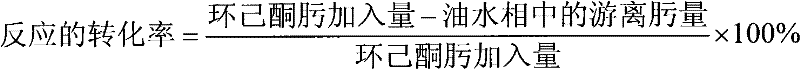

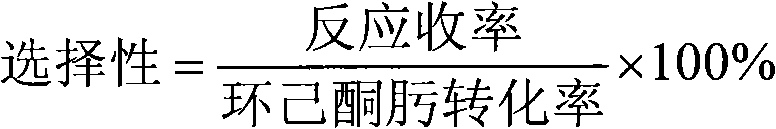

[0034] According to the same method as in Example 1, the temperature of the reaction system was increased from 70°C to 80°C, and other conditions were the same as those in Example 1. The product was analyzed, and the conversion of the reaction reached 100%, and the selectivity reached 99.9%.

Embodiment 3

[0036] According to the same method as in Example 1, in step (1), the flow rate of the dispersed phase was increased from 0.8 mL / min to 0.9 mL / min, and the acid oxime ratio was 1.19 at this time. The temperature of the reaction system was increased from 70°C to 80°C, and other conditions were the same as those in Example 1. The product was analyzed, and the conversion of the reaction reached 100%, and the selectivity reached 99.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com