Device and method for preparing alicyclic amine through continuous hydrogenation reduction of aromatic amine

A technology for cycloaliphatic amines and aromatic amines, which is applied in the field of continuous hydrogenation reduction of aromatic amines to prepare cycloaliphatic amines, which can solve the problem of unsatisfactory mixing effects, difficulty in achieving high-efficiency mixing, and inability to remix products, etc. problem, achieve the effect of solving the problem of reaction heat removal, improving controllability and safety, and not inactivating the activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

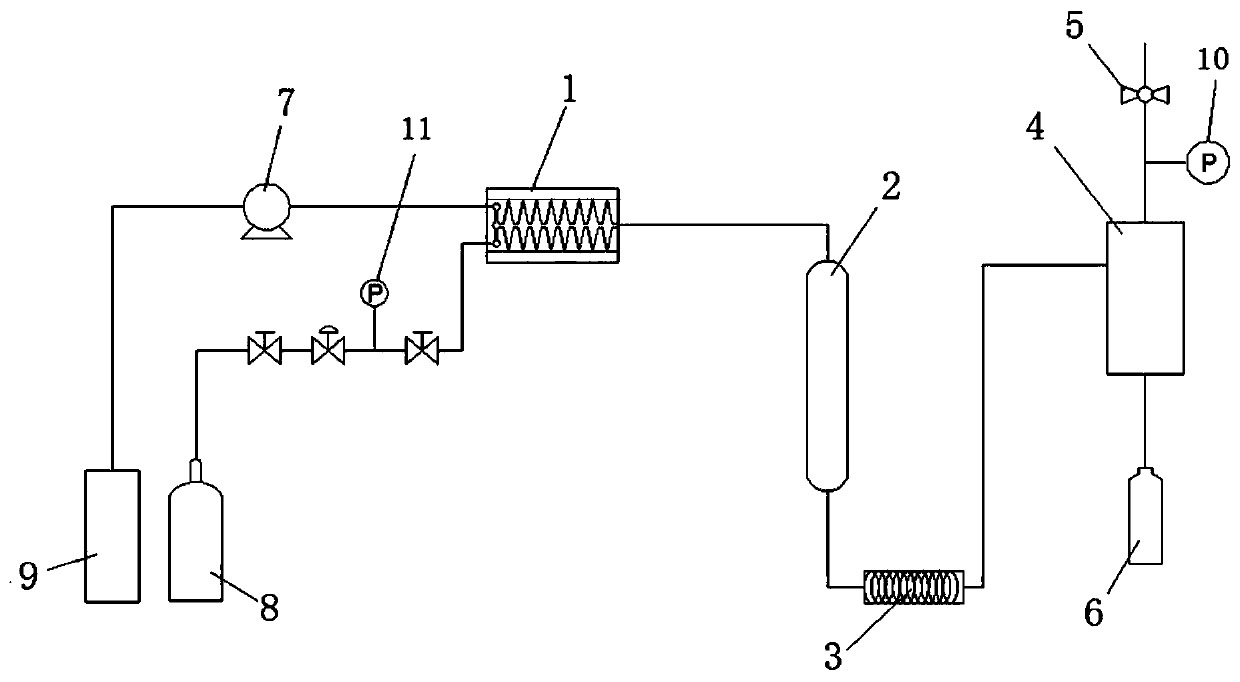

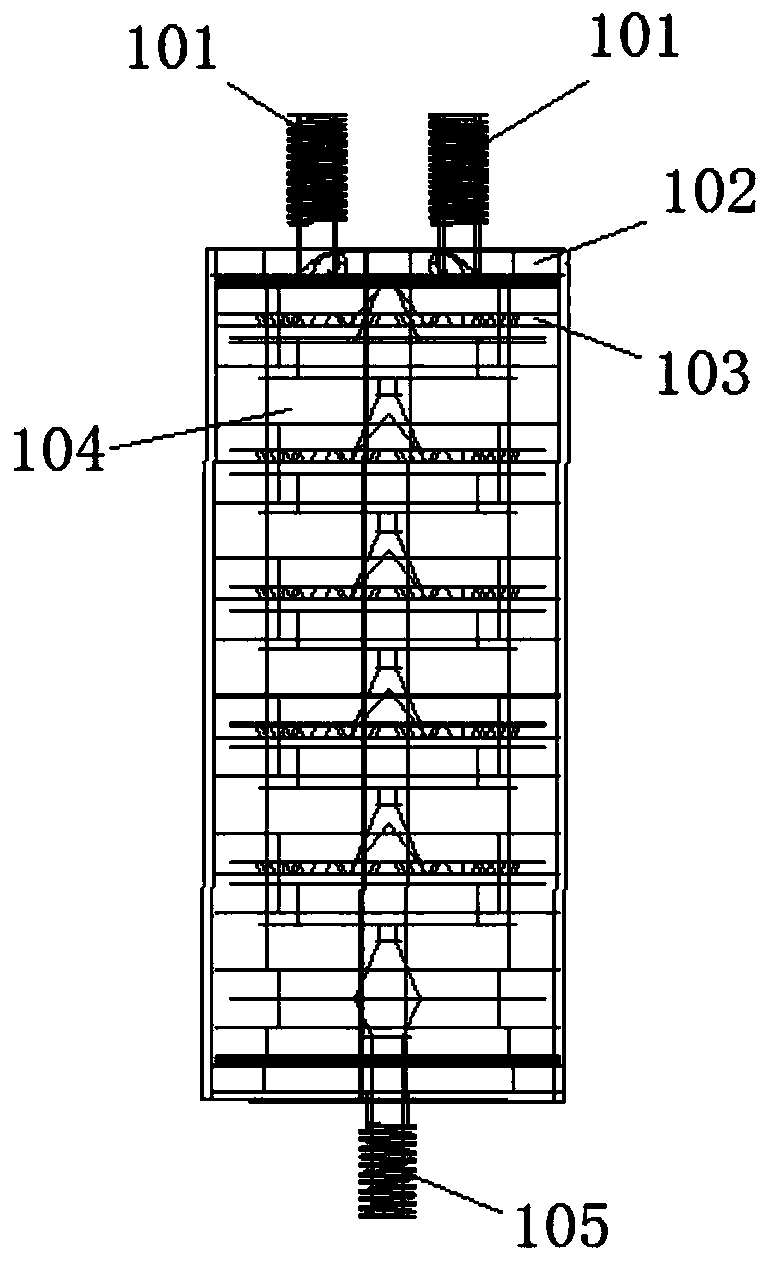

[0035] device such as figure 1 Shown, the present invention comprises raw material tank 9, gas cylinder 8, micro-mixer 1, micro-packed bed 2, delay pipeline 3, gas-liquid separation tank 4 and storage tank 6, wherein as figure 2 As shown, the micro-mixer 1 is provided with two material inlets 101 and a material outlet 105, and the raw material tank 9 is connected to a material inlet 101 of the micro-mixer 1 through a first pipeline, and The first pipeline is provided with an input pump 7, and the input pump 7 is used to input the raw materials into the micro-mixer 1, and the gas bottle 8 is fed into another material of the micro-mixer 1 through the second pipeline. Port 1 is connected, and the second pipeline is provided with an air inlet control valve, a gas flow meter for detecting gas flow, and an air inlet pressure gauge 11 for detecting air pressure, the outlet 105 of the micro mixer 1, the micro filling The bed 2, the delay pipeline 3, and the gas-liquid separation tan...

Embodiment 2

[0047] Using the device shown in the above embodiment, the micro-mixer 1 is provided with 5 flow plates 103 and 5 manifolds 104 for hydrogenation and reduction of aromatic amines to prepare cycloaliphatic amines. The specific steps are as follows:

[0048] Reaction equation

[0049]

[0050] (1) Preparation of reaction solution containing aromatic amine

[0051] 4,4'-methylenebis(2-diethyl)aniline (M-OEA for short) was selected as a raw material, and cyclohexane was used as a solvent to prepare a raw material reaction solution with a concentration of 1 mol / L.

[0052] (2) hydrogenation reduction reaction

[0053] Operating conditions: Under the conditions of temperature 110°C and pressure 1MPa, hydrogen gas with a purity of 99.99% and the above-mentioned raw material reaction solution are simultaneously passed into the micro-mixer 1 for dispersion and mixing, and the molar flow ratio of hydrogen gas to M-OEA is 10:1 , the micro-packed bed jacket is heated to 110 ° C, the ...

Embodiment 3

[0057] Using the device shown in the above embodiment, the micro-mixer 1 is provided with 8 flow plates 103 and 8 manifolds 104 for hydrogenation and reduction of aromatic amines to prepare cycloaliphatic amines. The specific steps are as follows:

[0058] Reaction equation

[0059]

[0060] (1) Preparation of working fluid containing aromatic amines

[0061] 4,4'-methylenebis(2-methyl-6-ethylaniline) (M-MEA for short) was selected as a raw material and tetrahydrofuran was used as a solvent to prepare a raw material reaction solution with a concentration of 1.4 mol / L.

[0062] (2) hydrogenation reduction reaction

[0063] Operating conditions: Under the conditions of temperature 120°C and pressure 2MPa, the hydrogen gas with a purity of 99.99% and the raw material reaction solution are simultaneously passed into the micro-mixer 1 for dispersion and mixing, and the molar flow ratio of hydrogen gas and M-MEA is 10: 1. Heat the jacket of the micro-packed bed to 120 ° C, the re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com