Reactor with multiple ring canal

A loop reactor and loop tube technology, applied in chemical/physical/physical chemical fixed reactors, chemical instruments and methods, chemical/physical/physical chemical processes, etc., can solve the problem of difficult large-scale devices and complex structures, etc. problems, to achieve the effect of easy large-scale, high degree of plug flow, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

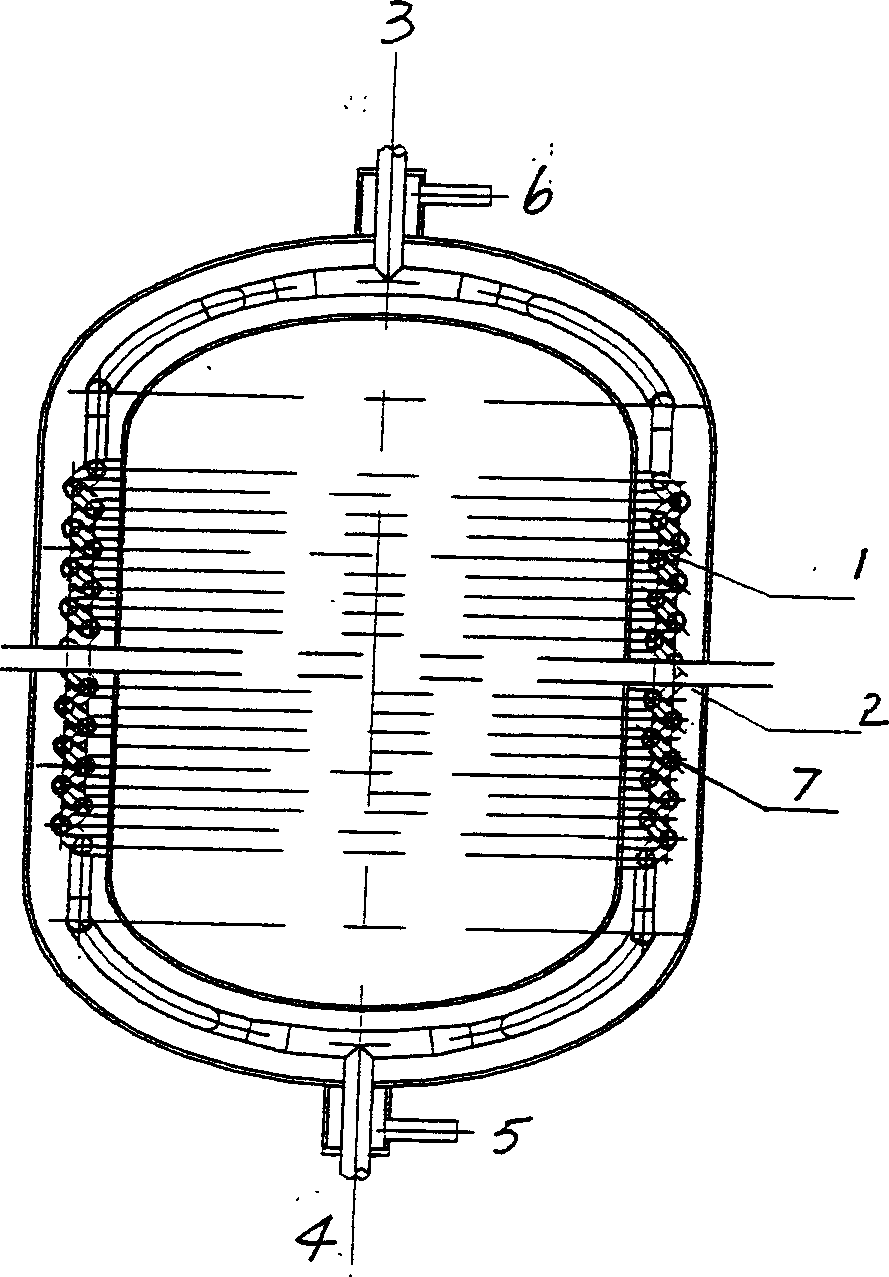

[0027] Multilayer loop reactor of the present invention is used as nylon 6 anionic polymerization reactor:

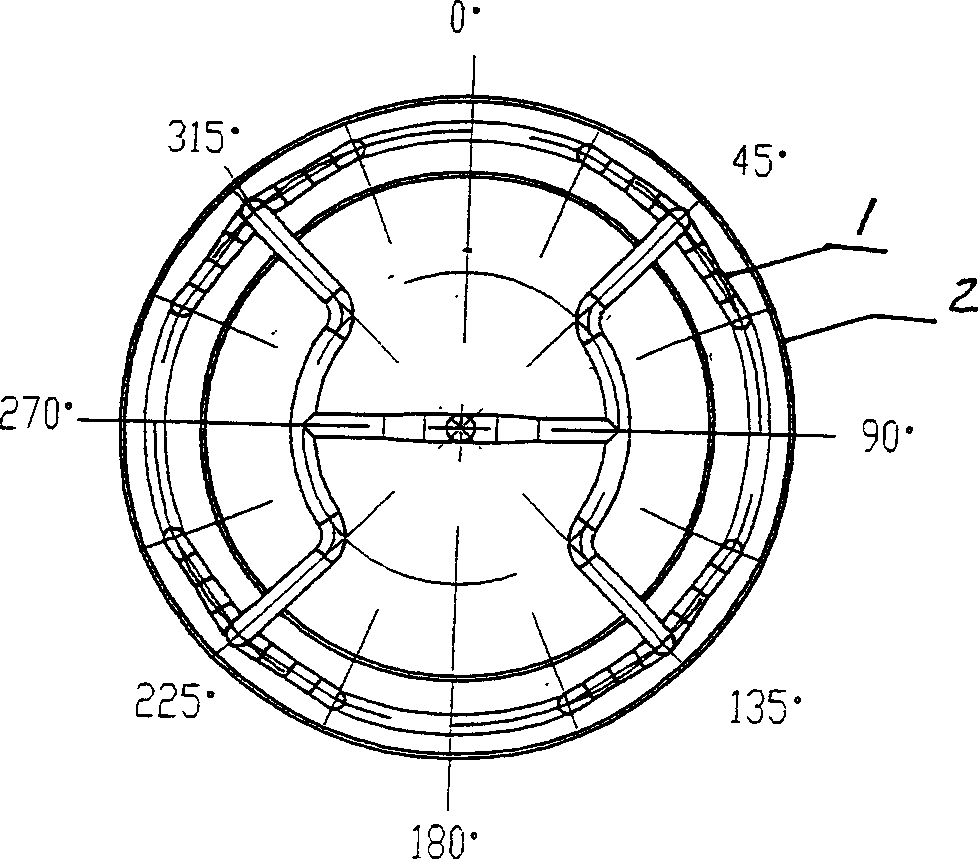

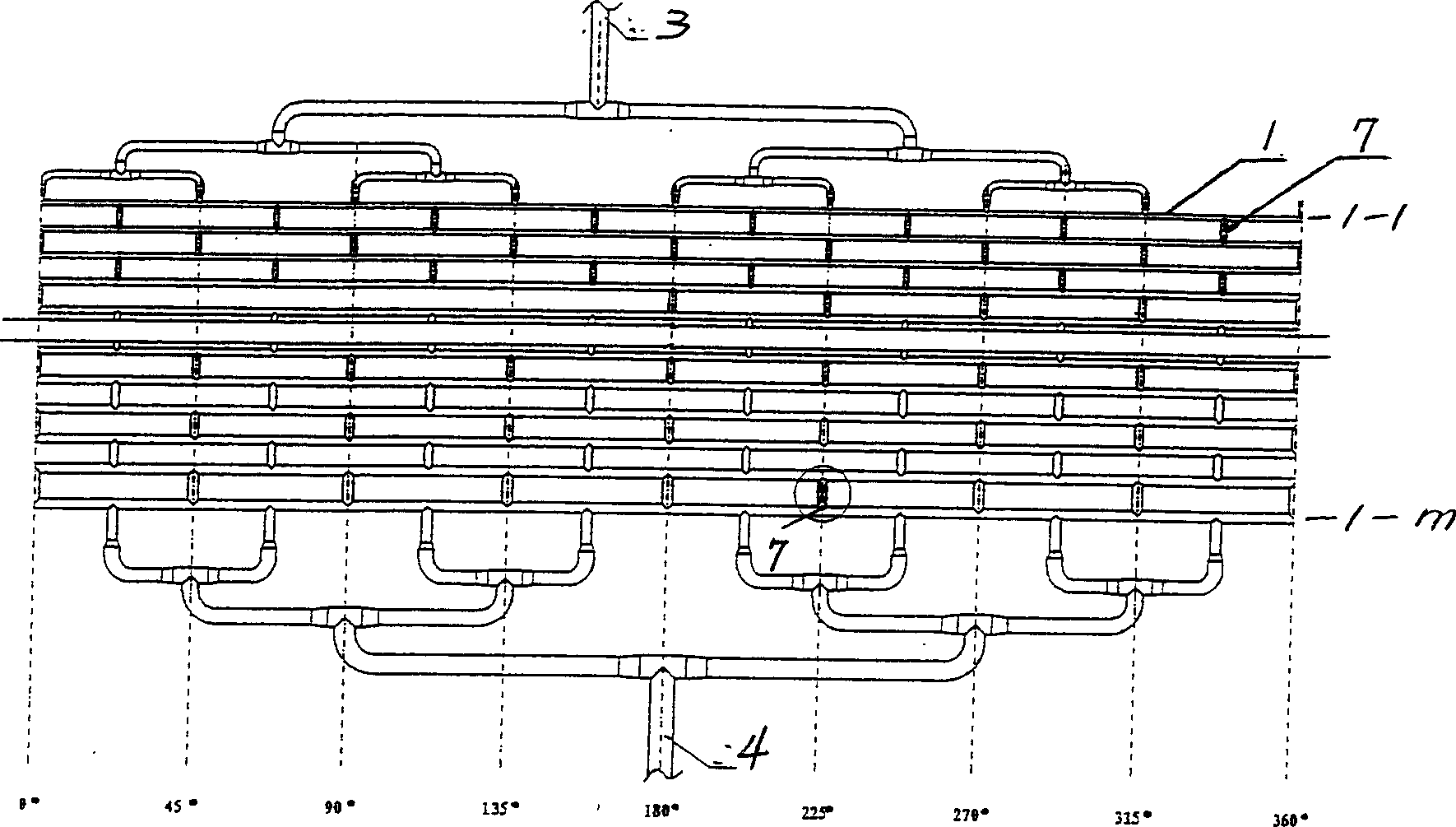

[0028] The reactor has a double-circle structure, the diameter of the outer ring is 2m, and the diameter of the inner ring is 1.9m. There are 80 layers in total, with 20 holes in each layer. The floor height is 50mm; the inner diameter of the ring pipe on the 41st to 60th floor is 35mm; the inner diameter of the ring pipe on the 61st to 80th floor is 40mm; the inner diameter of the upper main pipe is 70mm, and the inner diameter of the lower main pipe is 125mm. The diameter of the heat exchange outer cylinder is 2.15m, and the diameter of the heat exchange indoor cylinder is 1.75m.

[0029] Containing 0.1% (weight) NaOH and 0.1% (weight) toluene diisocyanate caprolactam enters the reactor from the upper main pipe, the temperature is 200°C, and the flow rate is 4500Kg / hour. The heat transfer oil enters the heat exchange chamber from the lower part, with a temperature of...

Embodiment 2

[0031] The multilayer loop reactor of the present invention is used as a polyethylene terephthalate (PET) cooler:

[0032] The reactor has a double-ring structure, with an outer ring diameter of 808 mm and an inner ring diameter of 700 mm, with a total of 40 layers; the inner diameter of each ring pipe is 40 mm, the number of short pipes is 16, and the inner diameter of the upper and lower main pipes is 150 mm. The diameter of the heat exchange outer cylinder is 950mm, and the diameter of the inner cylinder is 550mm.

[0033] The temperature of the PET melt to be cooled is 293°C and enters the cooler from the upper header with a flow rate of 6000Kg / hour. The heat transfer oil enters the heat exchange chamber from the bottom with a flow rate of 30,000-45,000Kg / hour and a temperature of 263-268°C. It leaves the cooler from the top at a temperature of 265-270°C. The PET melt leaves the cooler from the lower main pipe and the temperature drops to 282°C.

[0034] Compared with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com