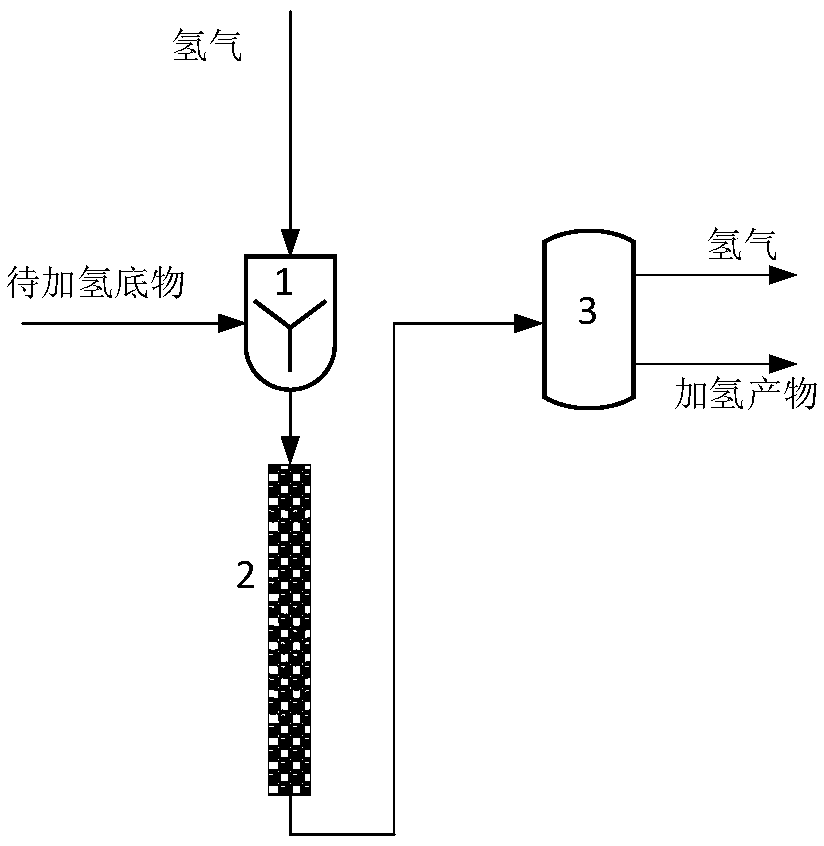

Hydrogenation reaction device in micropacked bed and method for hydrogenation reaction by using same

A technology for hydrogenation reaction and packed bed, applied in the field of chemical reaction, can solve the problems of small contact area of liquid phase and catalyst, low catalytic hydrogenation efficiency, large reactor volume, etc., so as to reduce the amount of catalyst and avoid local excessive hydrogenation , the effect of high mass transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Carry out experiment according to this method, be made into the solution that mass fraction is 10% by dissolving α-methylstyrene in methanol, control reaction temperature is 20 ℃, and pressure is 0.5MPa, in membrane dispersing micro-mixer (membrane average pore size 5 Micron) in the first hydrogen dispersed in the methanol solution to form a gas-liquid mixture containing microbubbles (average diameter of 200 microns), then through the micro-packed bed of palladium / alumina catalyst (average diameter of 600 microns) (packed bed inner diameter / catalyst The diameter ratio is 10, the packed bed aspect ratio is 16), the control liquid residence time is 0.5min, and the gas-liquid phase separation is carried out at the outlet of the micro-packed bed, and the methanol solution obtained is analyzed, and the conversion rate of the reaction is 100%. The yield of benzene is above 99%.

Embodiment 2

[0028] Carry out experiment according to this method, be made into the solution that mass fraction is 1% by dissolving α-methylstyrene in methanol, control reaction temperature is 30 ℃, and pressure is 1MPa, in sieve hole dispersion micro-mixer (screen hole characteristic aperture 200 microns) in the first hydrogen dispersed in the methanol solution to form a gas-liquid mixture containing microbubbles (average diameter 400 microns), then through the micro-packed bed of palladium carbon catalyst (average diameter 100 microns) (packed bed inner diameter / catalyst diameter Ratio is 40, and packed bed length-to-diameter ratio is 4), and the control liquid residence time is 5s, and gas-liquid phase separation is carried out at the outlet of micro-packed bed, and the methanol solution that obtains is analyzed, and the conversion efficiency of reaction is 100%, the cumene The yield is above 99%.

Embodiment 3

[0030] Carry out experiment according to this method, be made into the solution that mass fraction is 40% in the methanol that α-methylstyrene is dissolved, control reaction temperature is 80 ℃, and pressure is 2MPa, in membrane dispersion micro-mixer (membrane average aperture 10 microns ) in the first hydrogen dispersed in the methanol solution to form a gas-liquid mixture containing microbubbles (average diameter of 100 microns), then through the micro-packed bed of palladium / alumina catalyst (average diameter of 200 microns) (packed bed inner diameter / catalyst diameter ratio is 20, the packed bed aspect ratio is 100), the control liquid residence time is 5min, and the gas-liquid phase separation is carried out at the outlet of the micro-packed bed, and the methanol solution obtained is analyzed, and the conversion rate of the reaction is 100%, the cumene The yield was 98.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com