MEMS (Micro Electro Mechanical System) microphone and pressure integration sensor, and manufacturing method thereof

A technology integrating sensors and microphones, which is applied in the direction of sensors, electrostatic transducer microphones, semiconductor electrostatic transducers, etc., can solve the problems of complex packaging process, large device size, and high cost, so as to improve standardization and unification, and improve signal quality. Excellent noise ratio performance and high anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

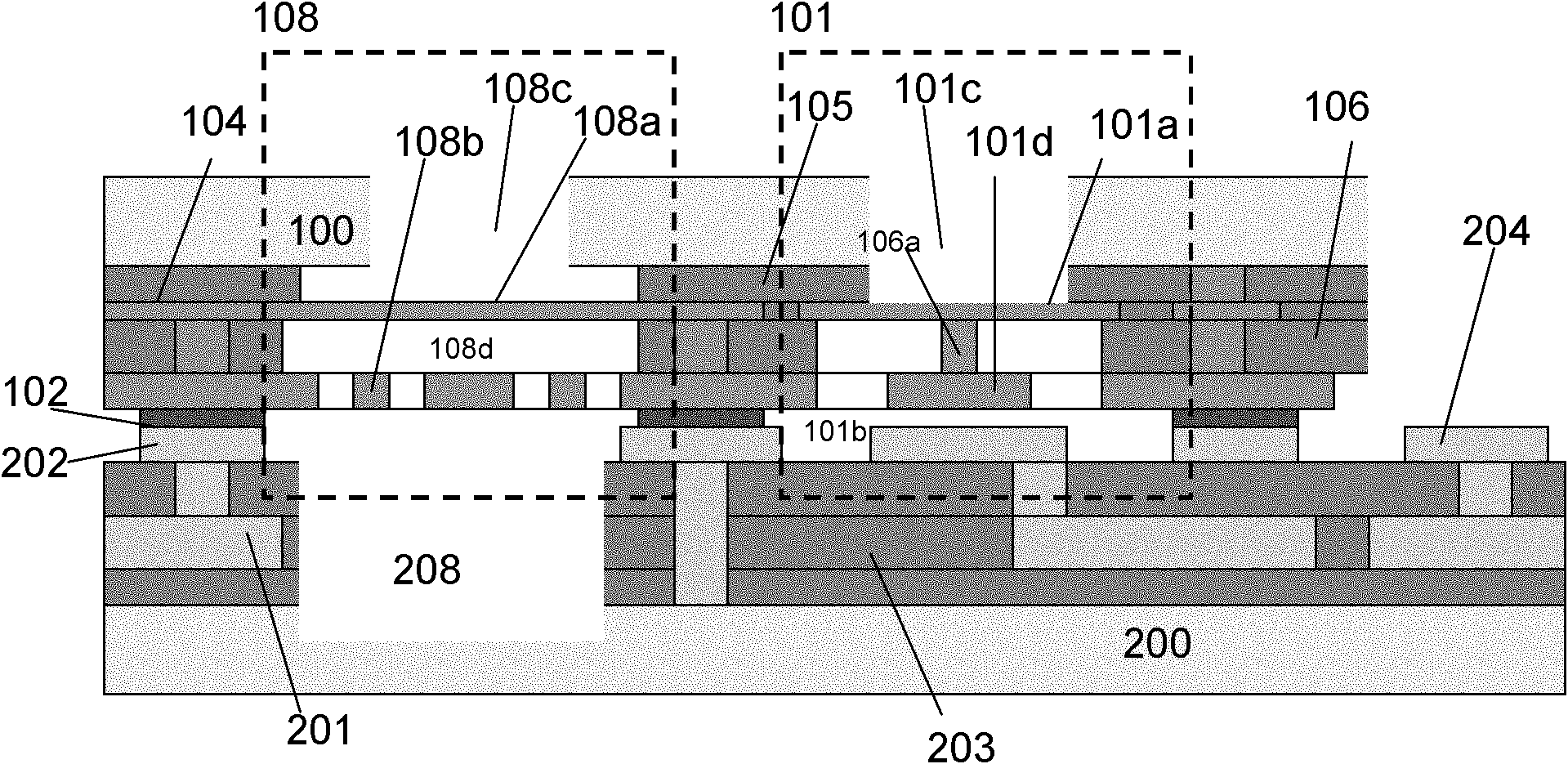

[0089] In the first embodiment, a part of the backside of the first substrate 100 is exposed outside the package. In other words, the first opening 108c and the second opening 101c serve as the inlets for sound and pressure, respectively, and introduce sound waves and pressure changes into the sensitive film and the sensing film. Above, different sound and pressure inlet designs can also be used, as detailed in the following examples.

Embodiment 2

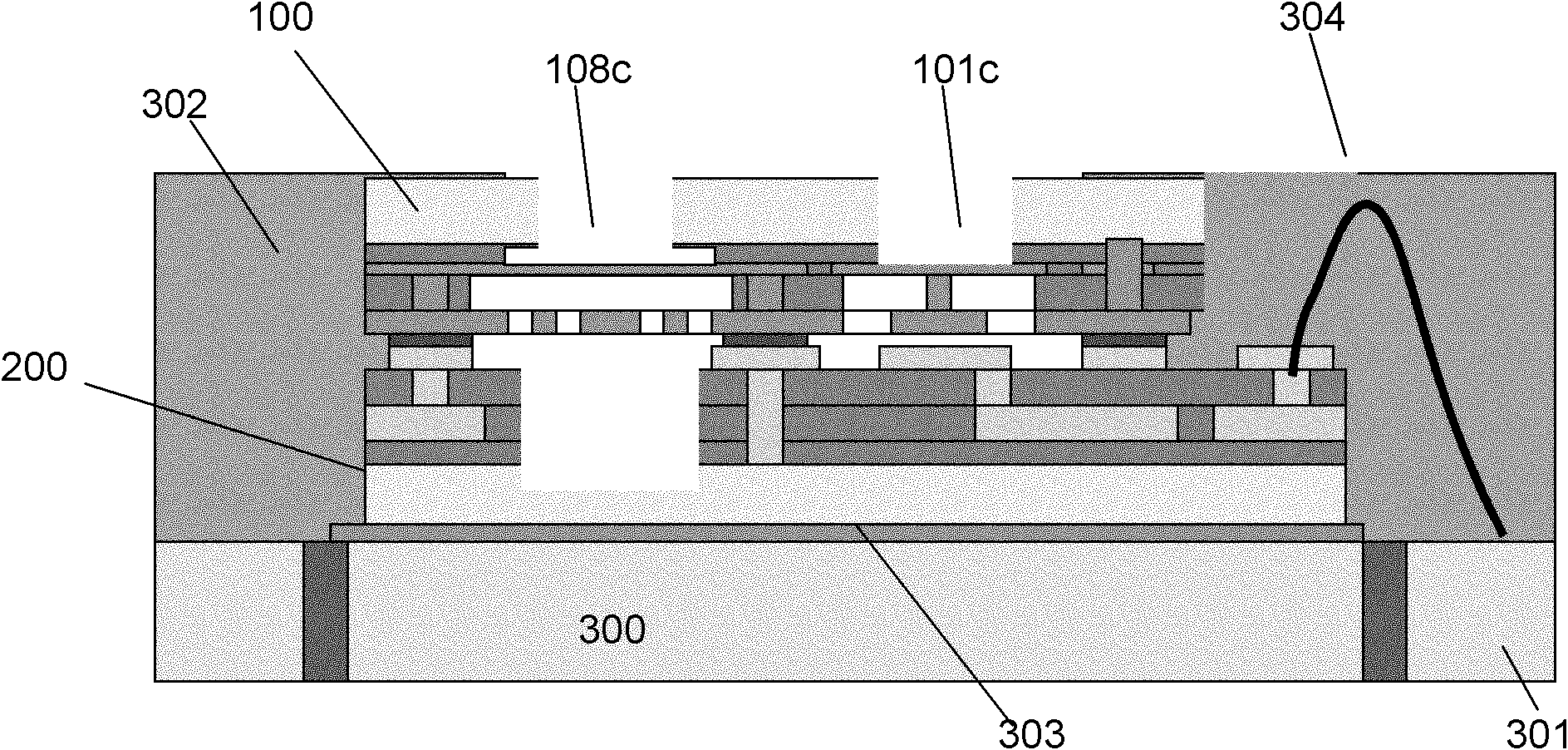

[0091] image 3 It is a schematic structural diagram of the MEMS microphone and the pressure integrated sensor described in this embodiment, Figure 4 for image 3 Schematic diagram of the package structure of the integrated sensor.

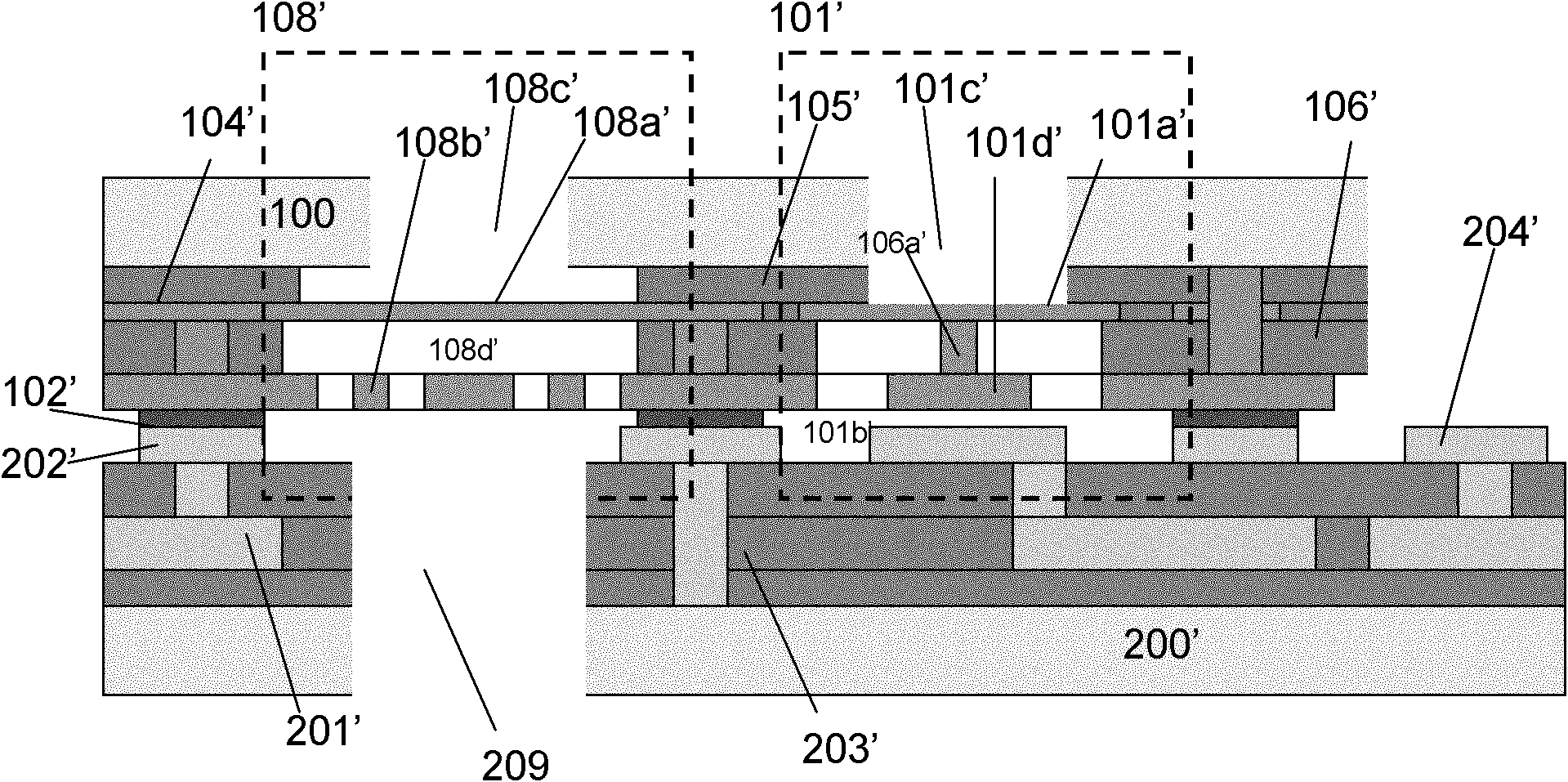

[0092] As shown in the figure, the difference between the MEMS microphone and the pressure integrated sensor is that the second substrate 200' has a third opening 109 on the back side (facing away from the first substrate 100'), which is different from the above-mentioned embodiment. The position of the sensitive film 108c' of the microphone unit corresponds to the position of the cavity 108d', and the sensitive film 108a' and the back plate electrode 108b' both have through holes, so the first opening 108c', the cavity 108d' and The third opening 209 forms a through channel in the first substrate 100' and the second substrate 200', which can simultaneously serve as a sound and pressure transmission channel.

[0093] After the first substrate ...

Embodiment 3

[0104] The manufacturing method of the MEMS microphone and the pressure sensor in the first embodiment will be described in detail below with reference to the accompanying drawings. Figure 5 It is a flowchart of the manufacturing method of the MEMS microphone and the pressure sensor described in the embodiment of the present invention, Figure 6 to Figure 13 It is a schematic diagram of the manufacturing method of the MEMS pressure sensor. As shown in the figure, the manufacturing method includes:

[0105] Step S1 : providing a first substrate, and forming the sensing film of the capacitive pressure sensing unit, the sensitive film of the microphone unit and the first adhesive layer on the surface of the first substrate on the first substrate.

[0106] Specifically, as Image 6 As shown, first, the first substrate 100 includes a silicon substrate, and a first dielectric layer 105 is formed on the silicon substrate. Preferably, the first dielectric layer 105 is a silicon oxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com