Dry desulfurization agent for ships, preparation method thereof, and ship dry desulfurization process

A dry desulfurization technology for ships, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems of by-product utilization, large equipment footprint, and a large amount of waste liquid, etc., to eliminate dust, Low power consumption and high desulfurization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

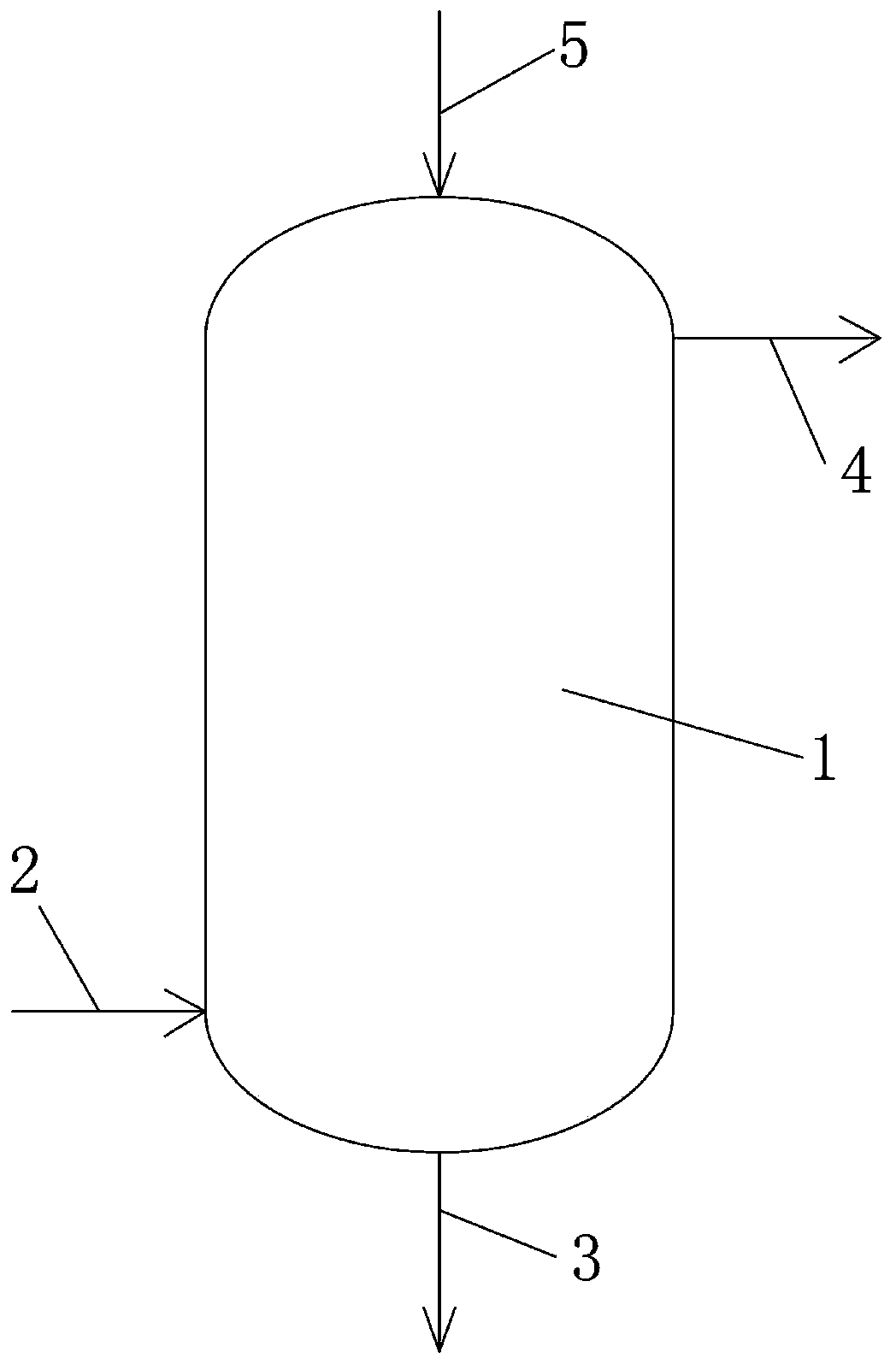

Image

Examples

Embodiment 1

[0039] Preparation and Evaluation of the Desulfurizing Agent of Example 1 Dry Desulfurization Process

[0040] Mix 30g of activated clay larger than 200 meshes and 70g of calcium hydroxide. After mixing evenly, add 50g of water and mix again. Dry for 12 hours to obtain a dry desulfurizer for ships.

[0041] At a flue gas temperature of 180°C and a SOx concentration of 500ppm, the desulfurization efficiency is 92.5% under the condition of a space velocity of 800 / h using the above-mentioned desulfurizer.

Embodiment 2

[0042] Preparation and Evaluation of Desulfurizer in Example 2 Dry Desulfurization Process

[0043] Mix 30g of activated clay greater than 200 meshes, 10g of attapulgite, 50g of calcium oxide and 10g of magnesium hydroxide. After mixing evenly, add 60g of water and mix again. After mixing evenly, carry out extrusion molding. °C for 4 hours, and then dried at 120 °C for 10 hours to obtain a dry desulfurizer for ships.

[0044] In the flue gas at 200°C, the SOx concentration is 700ppm, the desulfurization efficiency is 93.4% under the space velocity of 600 / h using the above desulfurizer.

Embodiment 3

[0045] Preparation and Evaluation of Desulfurizer in Example 3 Dry Desulfurization Process

[0046]Mix 20g of kaolin larger than 200 mesh, 20g of gypsum and 60g of magnesium hydroxide. After mixing evenly, add 40g of water and mix again. Dry at 120°C for 8 hours to obtain a dry desulfurizer for ships.

[0047] At a flue gas temperature of 220°C and a SOx concentration of 1000ppm, using the above-mentioned desulfurizer, the desulfurization efficiency is 91.3% under the condition of a space velocity of 800 / h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com