Low-oxygen low-nitrogen combustion system for coal-fired chain grate boiler

A chain boiler, low-nitrogen combustion technology, applied in the field of boiler combustion, can solve the problems of high nitrogen oxide content, difficult combustion of raw coal, low combustion temperature, etc., and achieves high temperature, which is beneficial to waste heat recovery and improves combustion efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

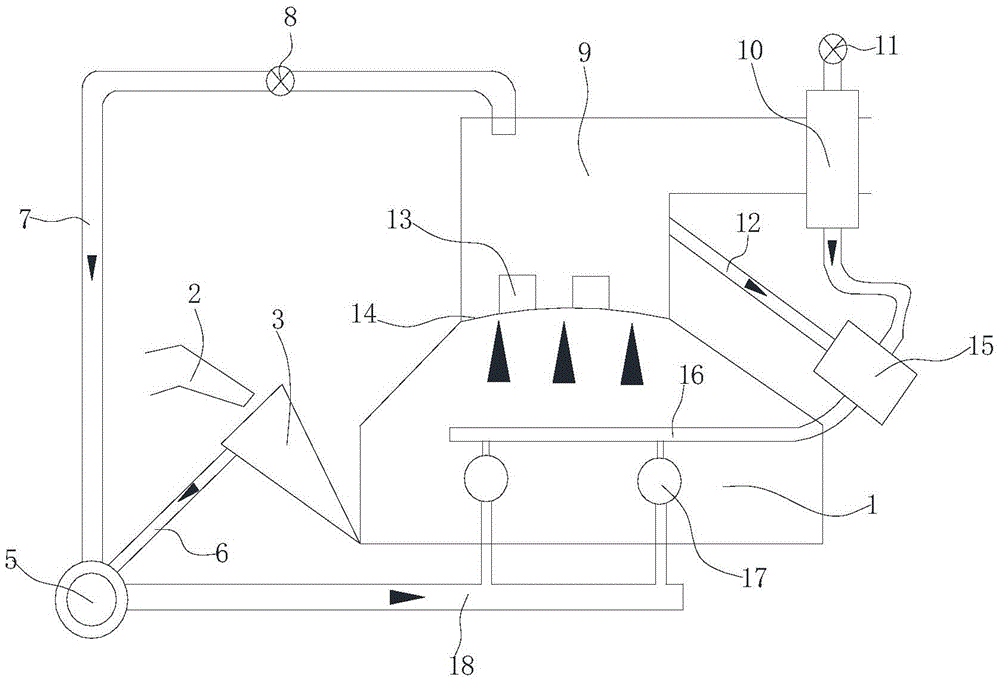

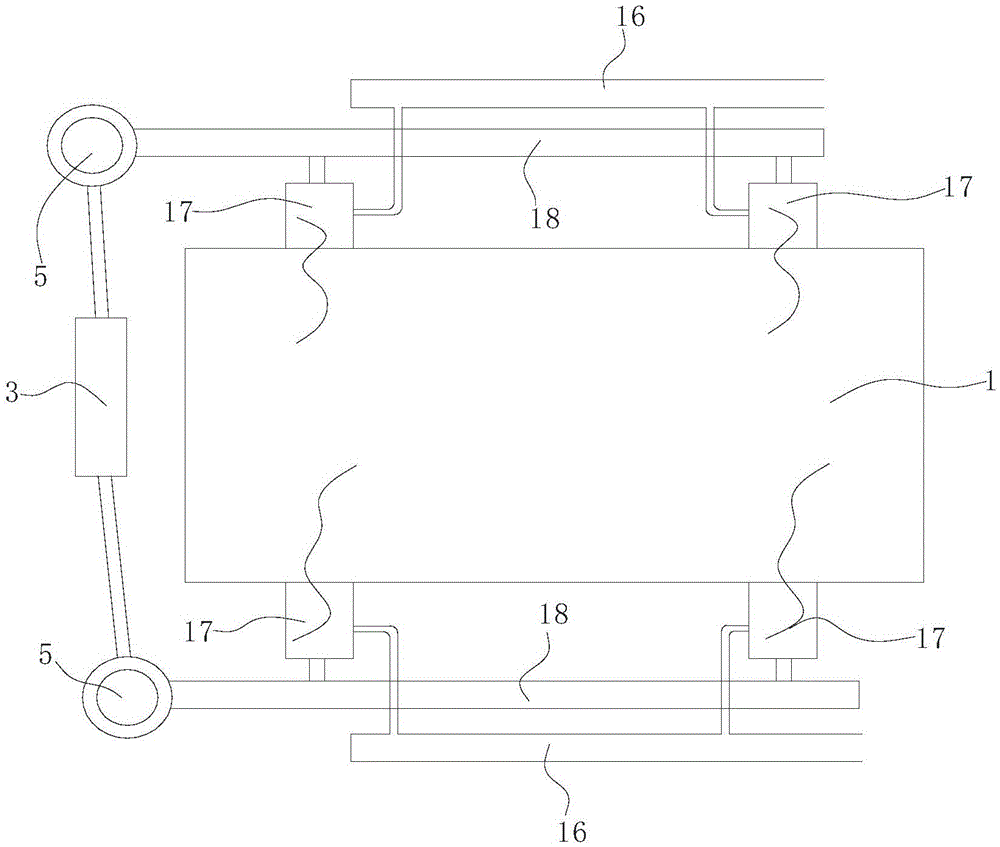

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

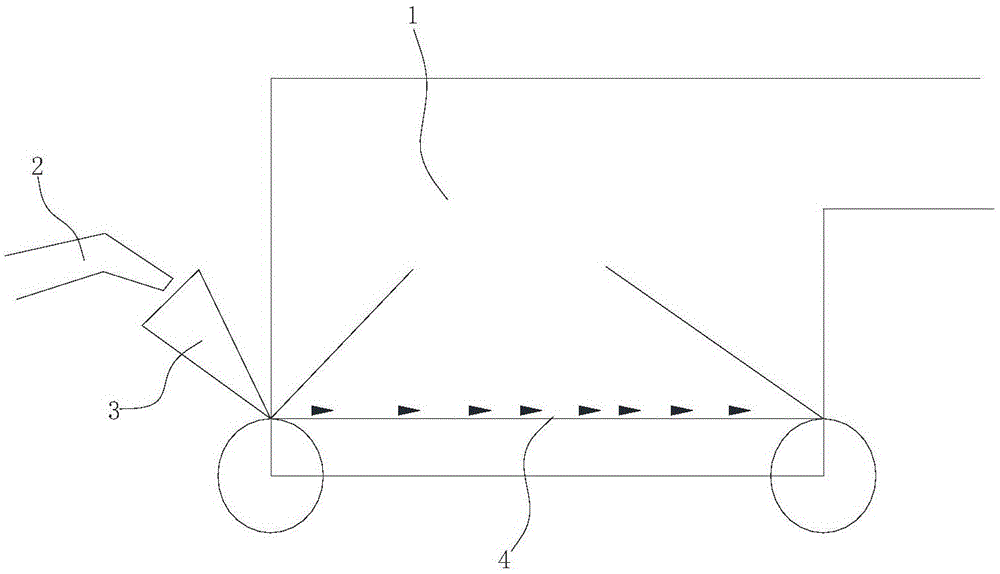

[0020] Coal-fired chain boiler low-oxygen low-nitrogen combustion system, such as figure 2 and image 3 As shown, it includes a furnace 1, a combustion cylinder 17, a fan coal mill 5 and a fuel delivery pipe 18. A partition 14 is arranged in the furnace 1 to divide the furnace 1 into a combustion zone and a heat absorption zone 9. On the partition 14 At least one heat conduction channel 13 is provided to communicate the combustion zone with the heat absorption zone 9 . The baffle 14 can make the high-temperature combustion flame entering the combustion zone fully superimposed and mixed, which is beneficial to increase the combustion temperature and make the fuel burn more fully. Two combustion cylinders 17 are respectively arranged on two opposite side walls of the furnace 1 , and the combustion cylinders 17 are connected and communicated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com