Waste Heat Recovery System and Method Thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

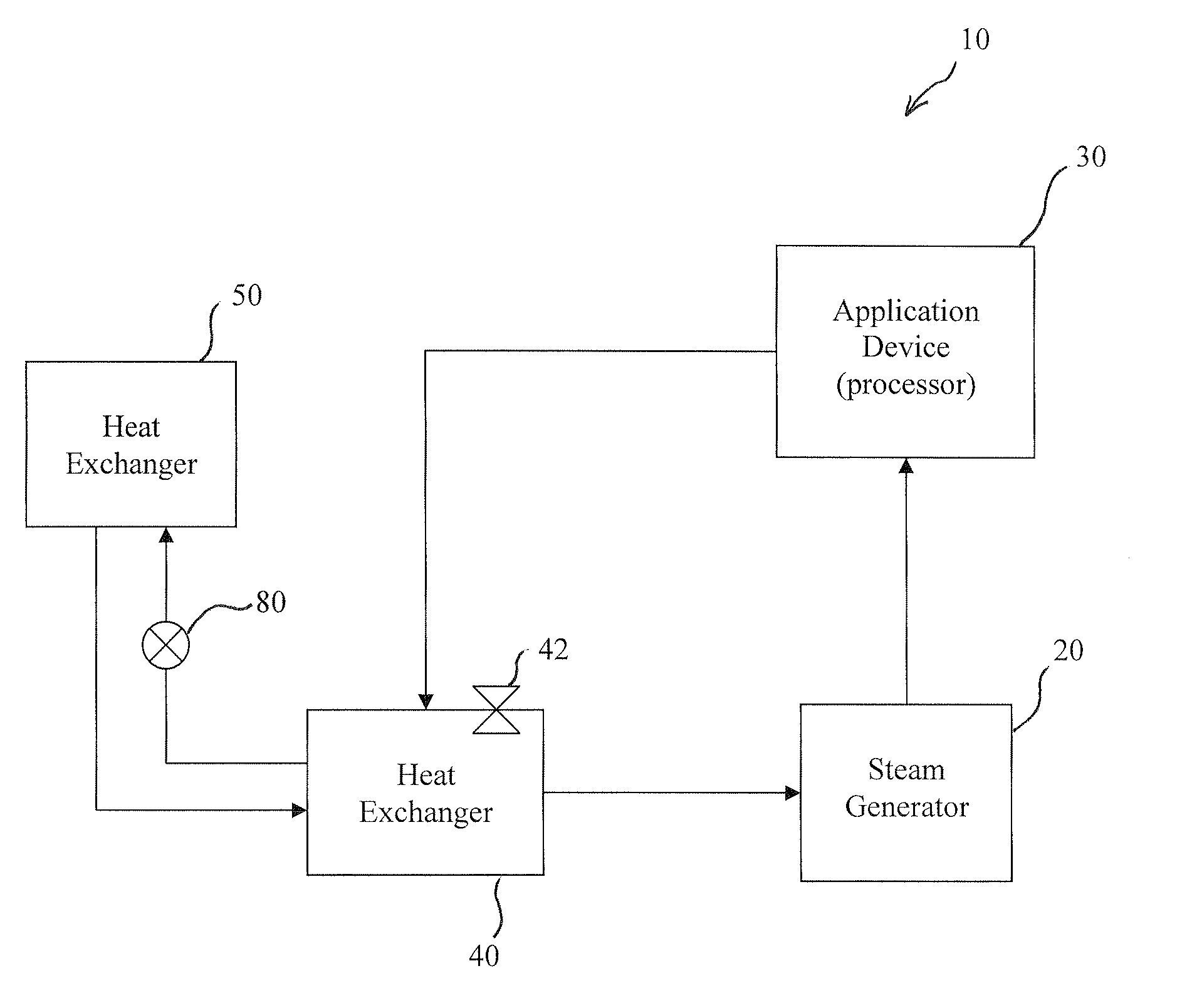

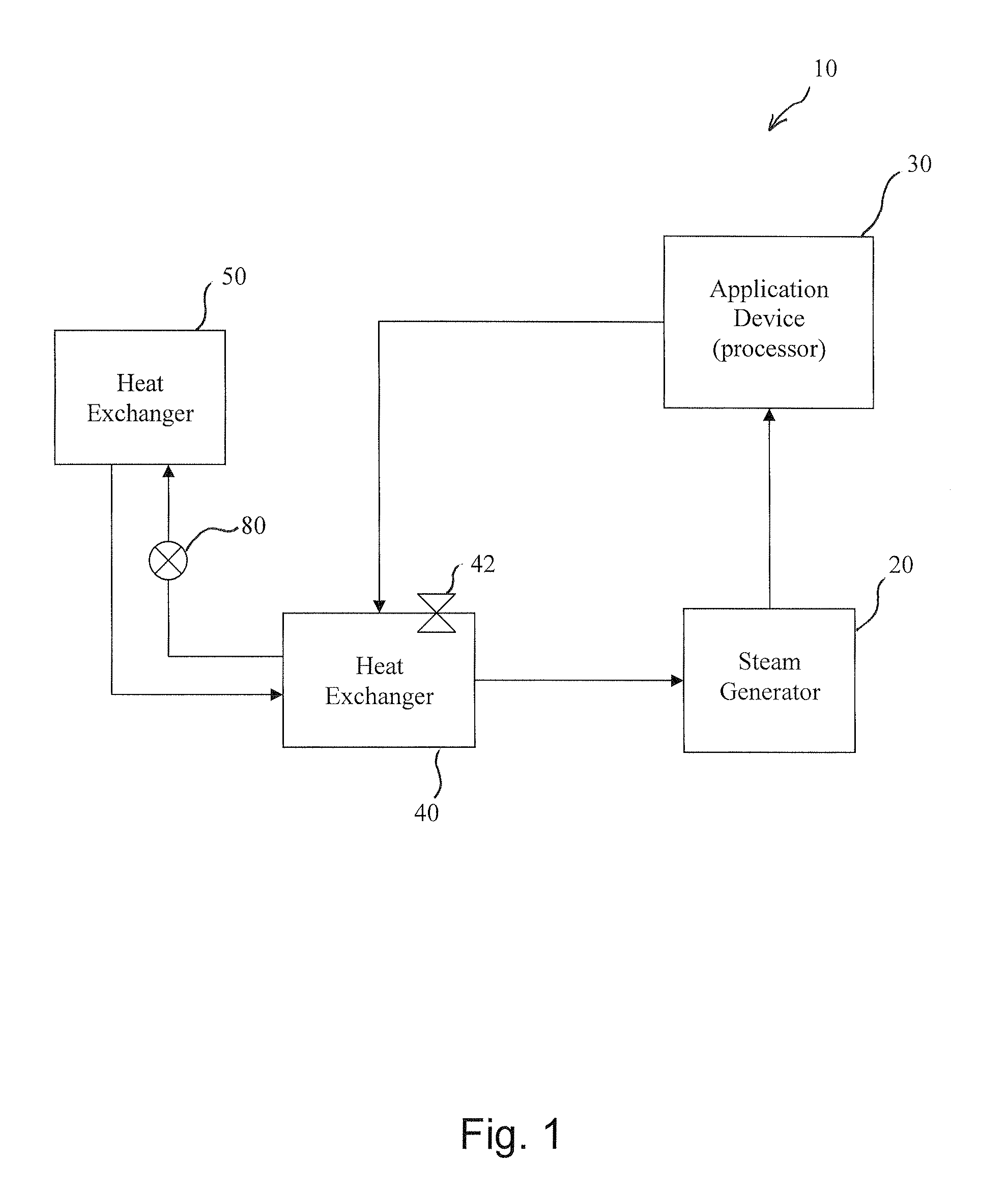

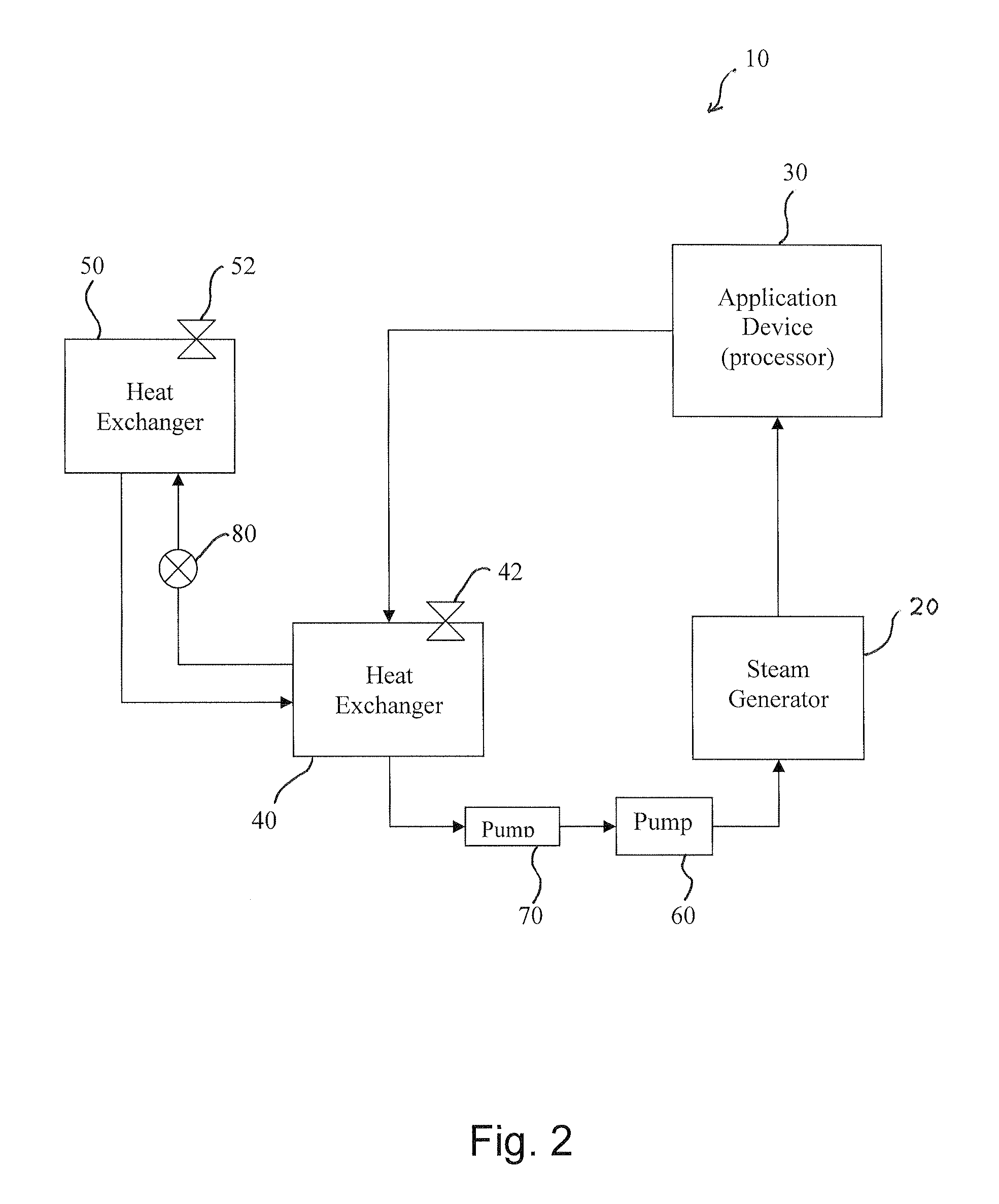

[0046]FIG. 1 is a schematic block diagram of a waste heat recovery system 10 according to an embodiment of the present invention. FIG. 2 is a schematic block diagram of a waste heat recovery system 10 according to another embodiment of the present invention. FIG. 3 is a schematic block diagram of a waste heat recovery system 10 according to still another embodiment of the present invention.

[0047]The waste heat recovery system 10 comprises a steam generator 20, a processor 30, a first heat exchanger 40, and a second heat exchanger 40.

[0048]The steam generator 20 is configured for generating an original steam using water.

[0049]The processor 30 is configured to use the original steam from the steam generator 20 and emit water and a first steam. The processor 30 may include a plurality kinds of thermal applications such as boiler systems and steam engines, which take in steam of high temperature and pressure to exert work to internal or external loads. The first steam usually has temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com