A kind of production system of corn pulping fiber

A production system and pulp fiber technology, applied in the fields of feed, food science, application, etc., can solve the problems of low drying efficiency, poor product quality, large air volume, etc., and achieve good exhaust gas quality, low steam and power consumption, and drying efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

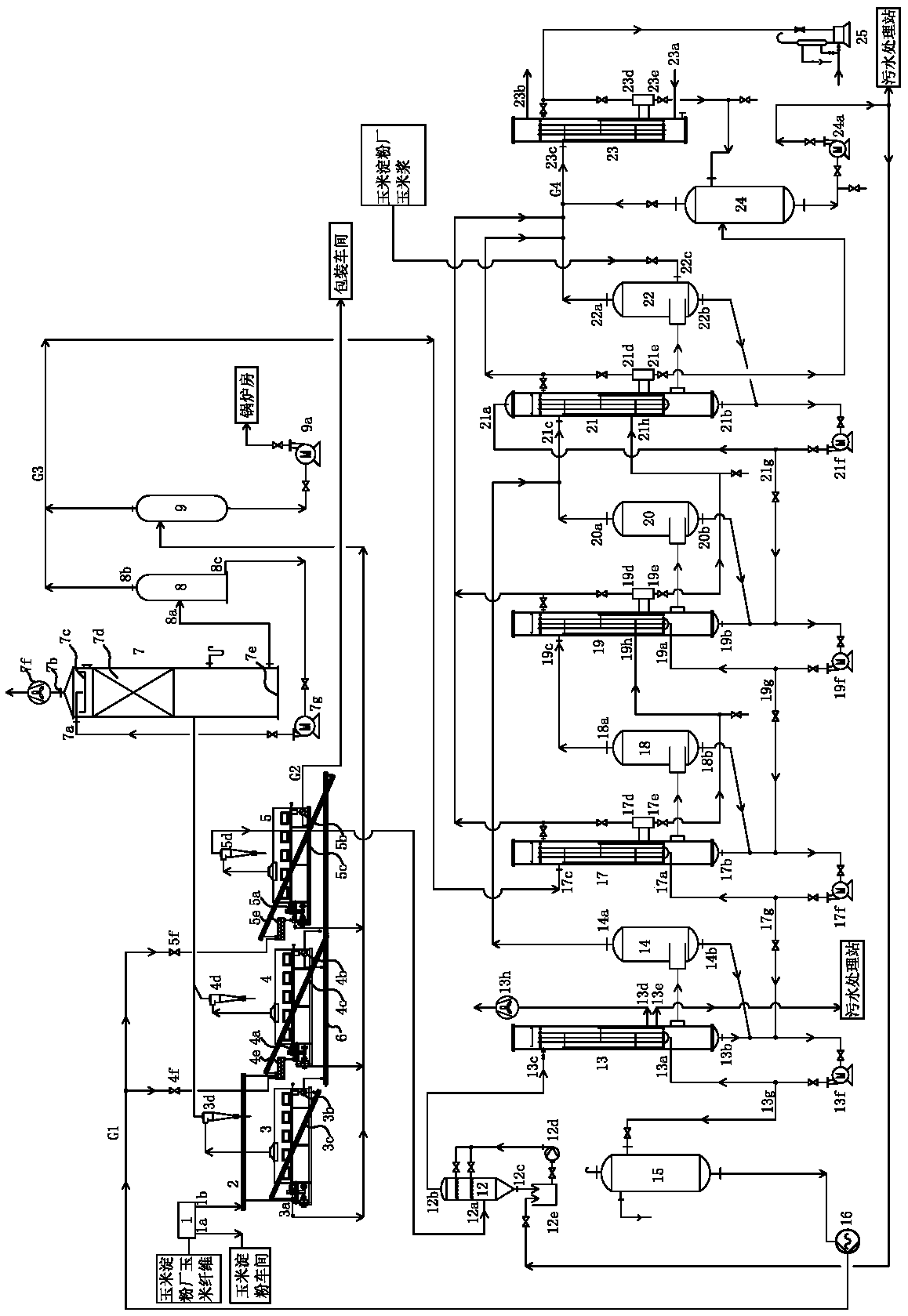

[0020] Such as figure 1As shown, the production system of corn pulping fiber of the present invention comprises the screw dehydrator 1 that the corn fiber of corn starch factory is dehydrated, and the dehydration liquid outlet 1a of screw dehydrator 1 is connected with cornstarch workshop, and the dehydrated corn fiber of screw dehydrator 1 The outlet 1b is connected to the inlet of the feeding screw conveyor 2, the first outlet of the feeding screw conveyor 2 is connected to the inlet of the first feeding screw 3a of the first tube bundle dryer 3, and the first tube bundle dryer The discharge port of 3 is connected with the inlet of the first three-way distribution valve 3b, and the return port of the first three-way distribution valve 3b is connected with the lower end inlet of the first return screw conveyor 3c, and the first return screw conveys The top outlet of the machine 3c is connected with the inlet of the first feed screw 3a; the discharge port of the first three-wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com