Energy-saving and environment-friendly combustion system of layer-burning boiler

An energy-saving and environmentally friendly combustion system technology, which is applied in the field of boiler combustion, can solve the problems of high nitrogen oxide content, difficulty in burning raw coal, and low combustion temperature, and achieve high temperature, beneficial waste heat recovery, and high combustion efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

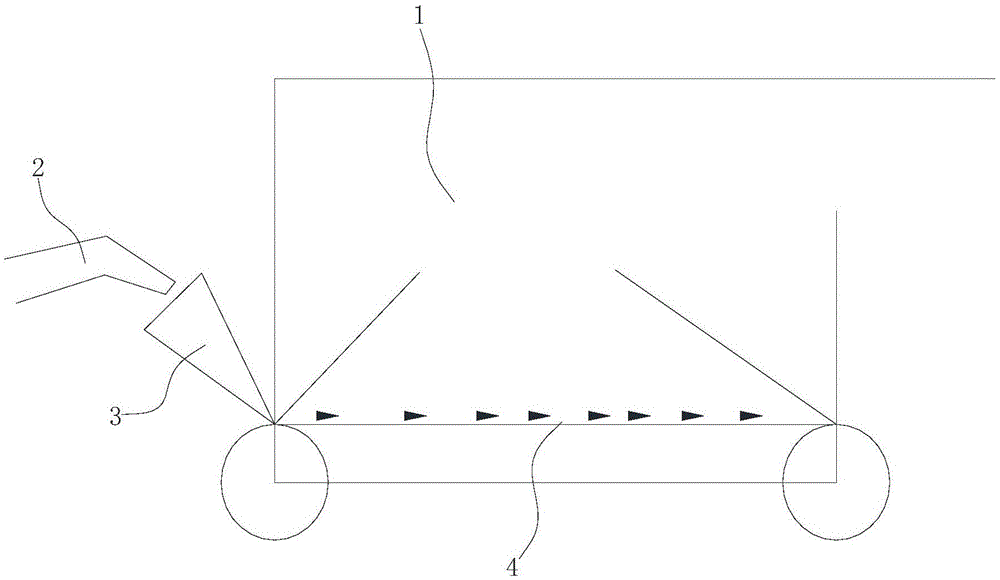

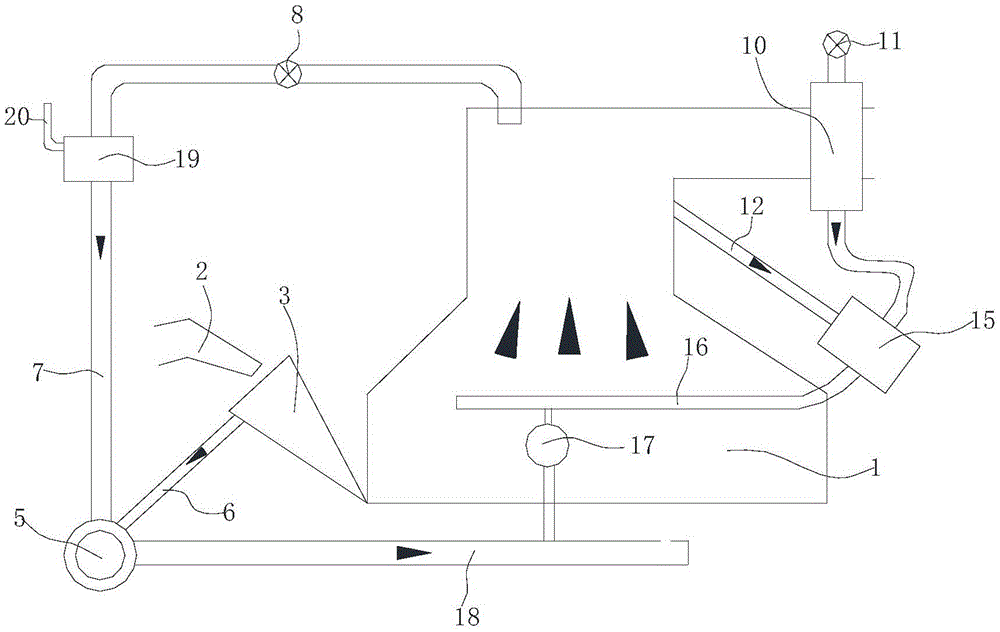

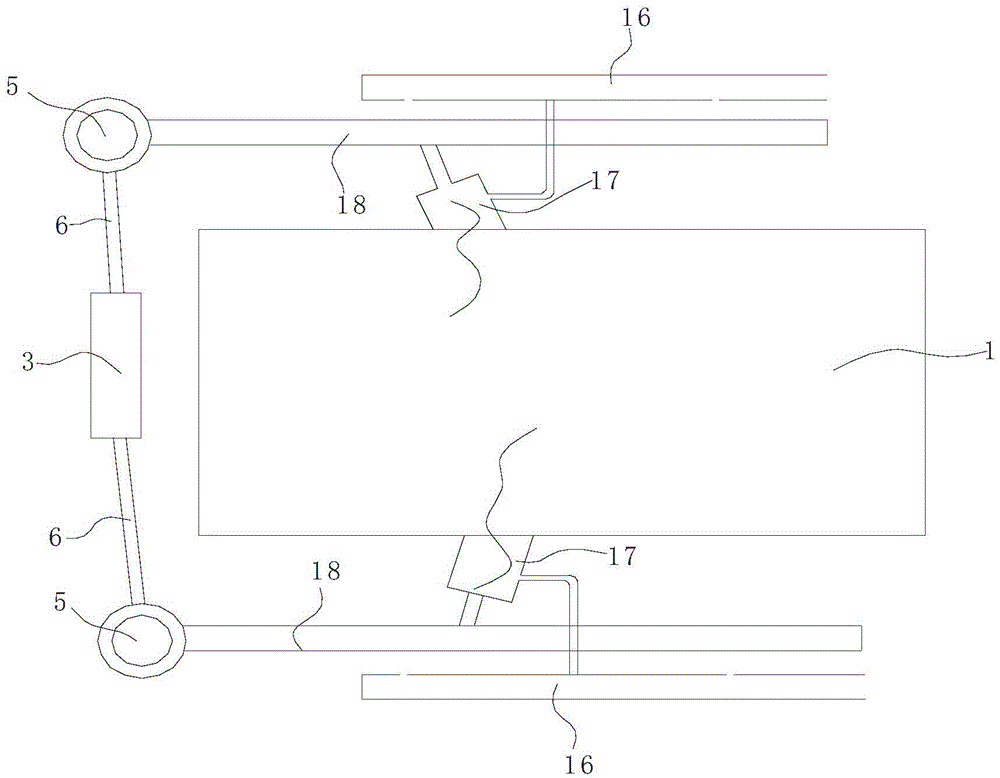

[0024] The energy-saving and environment-friendly combustion system of the floor-fired boiler, such as figure 2 and image 3 As shown, it includes a furnace 1 , a combustion cylinder 17 , a fan coal mill 5 and a fuel delivery pipe 18 . At least one combustion tube 17 is provided on the side wall of the furnace 1 , and the combustion tube 17 is connected to the furnace 1 . An opening is set above the front part of the furnace 1 to connect with the first flue gas introduction pipe 7, and the first flue gas introduction pipe 7 is connected with the fan coal mill 5, and the fan coal mill 5 is connected with the raw coal input pipe 6 connection, the output port of the fan coal mill 5 is connected to the combustion cylinder 17 through the fuel delivery pipe 18 to provide fuel for the combustion cylinder. The bottom of the rear part of the furna...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Top angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com