Decontamination system for wastewater heat exchanger

A technology for heat exchangers and waste water, which is applied in the direction of cleaning heat transfer devices, lighting and heating equipment, and non-rotating equipment cleaning. It can solve the problems of waste heat waste and waste heat recovery and utilization of waste water that are difficult to popularize and apply, and achieve the effect of improving service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

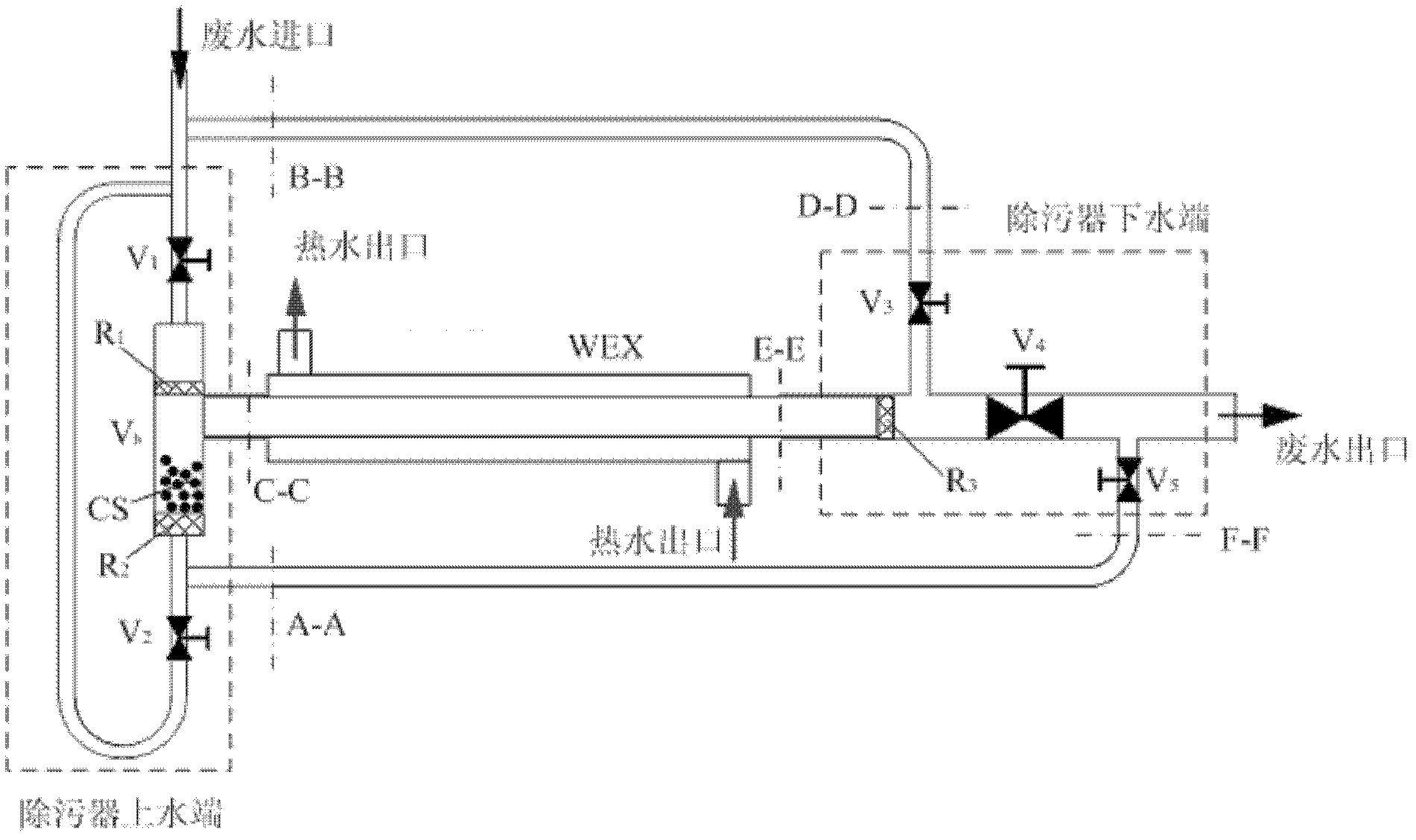

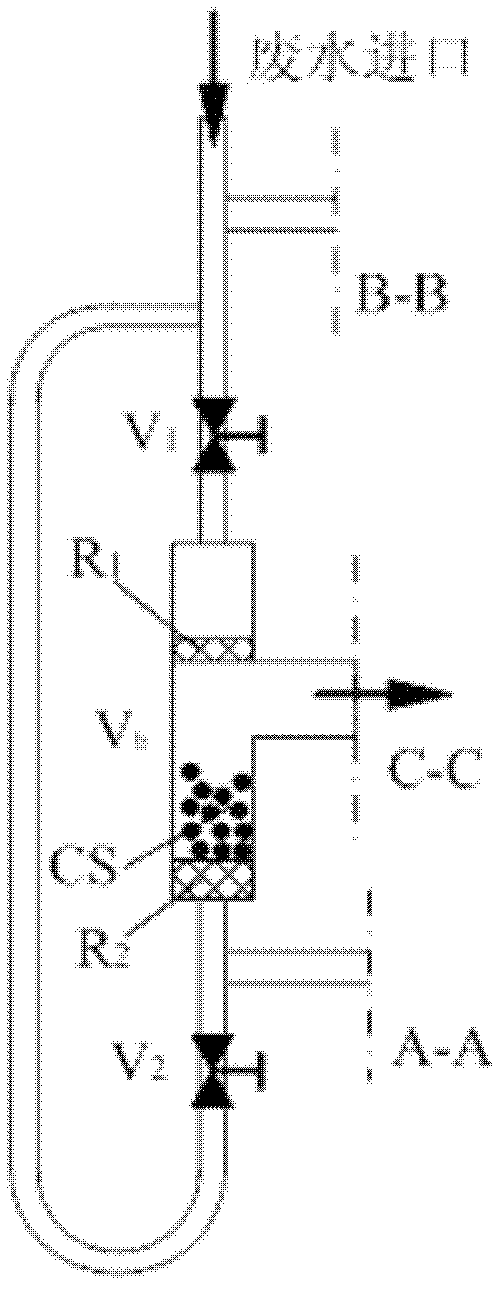

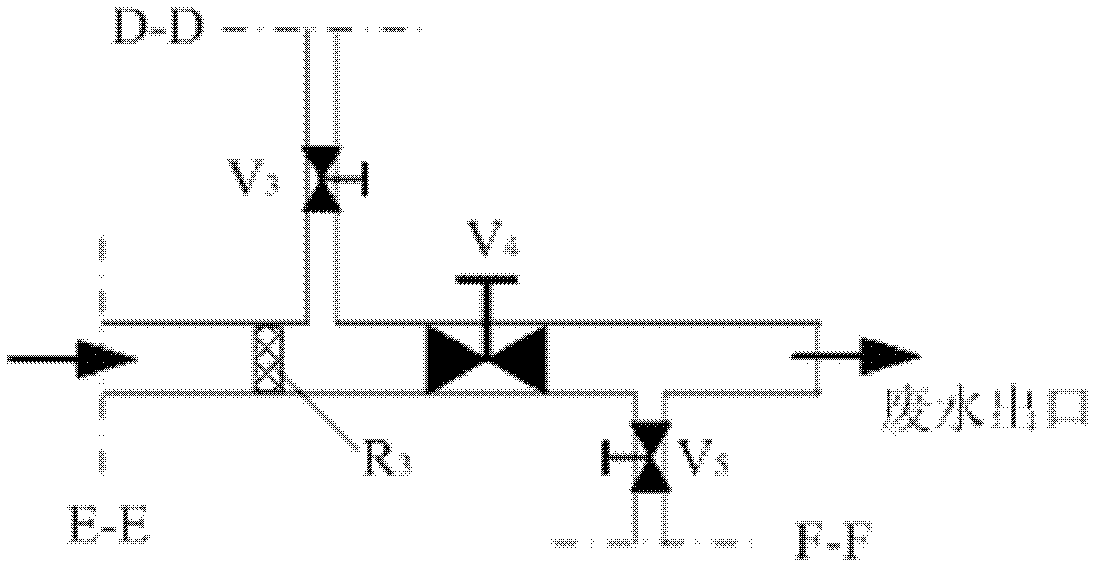

[0016] Such as Figure 1-3 As shown, a waste water heat exchanger decontamination system of this embodiment is composed of the upper water end of the decontamination device, the lower water end of the decontamination device, the water-water heat exchanger WEX, connecting pipelines, valves and other accessories. The connecting pipelines in the system are divided into clean water pipelines and waste water pipelines. Among them, the water-to-water heat exchanger is a casing heat exchanger or a shell-and-tube heat exchanger. The upper water end of the decontamination device is connected by the first filter R 1 , the second filter R 2 , decontamination ball CS, decontamination ball storage room V b , connecting pipeline, valve V 1 , V 2 and other accessories; decontamination ball storage room V b The first filter R is installed on both sides of the straight pipe section on the wastewater inlet side 1 , the second filter R 2 , the other outlet C-C is connected to the waste wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com