Production process for preparing calcium carbide from calcium coke pellets in graded oxygen heating mode

A production process, the technology of oxythermal method, which is applied in the field of coal chemical industry, can solve the problems such as difficulty and complexity of calcium carbide heat recovery, unreasonable selection of calcium-coke ratio, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

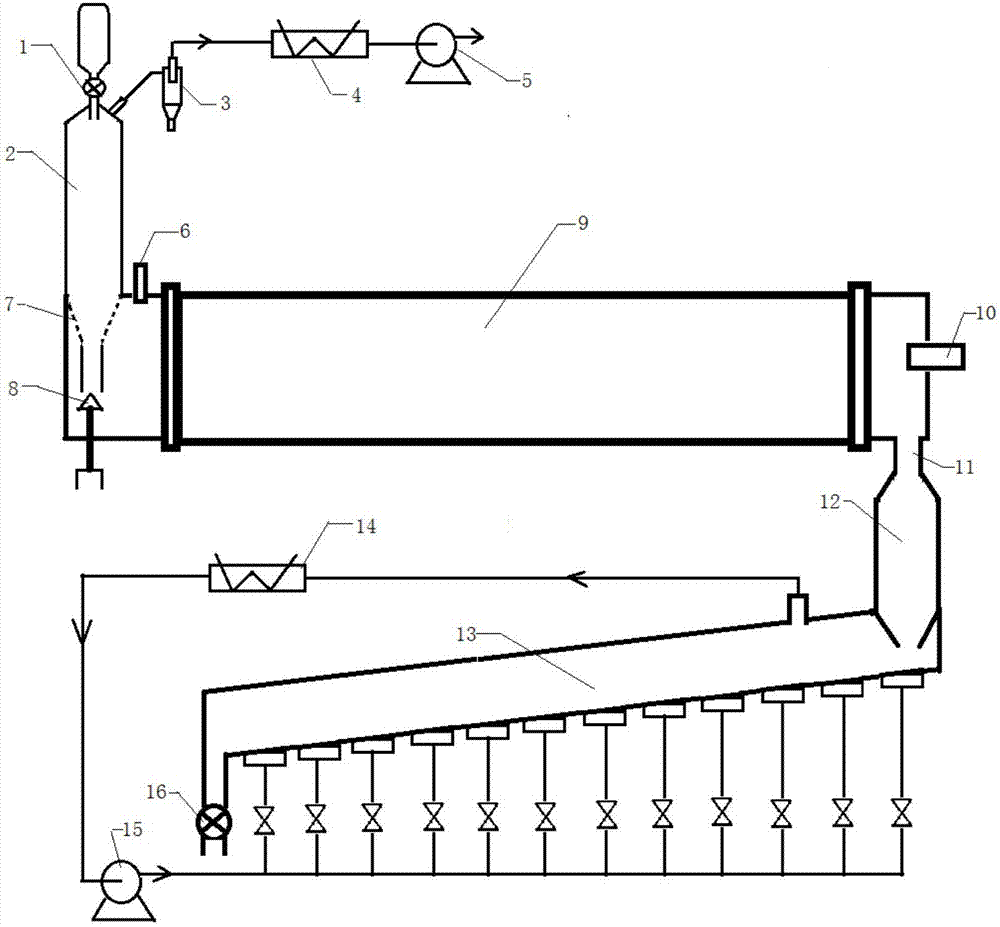

[0023] In an embodiment, calcium coke pellets of 5-30 mm are fed into the moving bed preheater (2) through the feeder (1), and are exchanged countercurrently with the air combustion flue gas rising from the bottom of the moving bed preheater (2). Heat to 600-1300°C, and then control the flow into the kiln tail of the rotary kiln reactor (9) through the high-temperature plug valve (8) at the bottom of the moving bed preheater (2); °, 2.0-50 rpm rotary kiln is heated to 1400-1900°C by the coke powder and oxygen high-temperature flame sprayed by the coke powder oxygen burner (10) at the kiln head, and the reaction generates calcium carbide and emits CO, which contains CO and H 2 The high-temperature reaction gas flows countercurrently to the kiln tail and is mixed with air and coke powder through the coke powder air burner (6) to generate air combustion flue gas for preheating; the generated calcium carbide flows into the heat preservation movement from the kiln head outlet (11) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com