Control system for palletizing robot and realization method of control system

A palletizing robot and control system technology, applied in the field of palletizing robot control systems, can solve the problems of danger, uneven levels, and inability to guarantee the correctness of the programming language of the palletizing robot, so as to ensure safety and reliability, reduce Difficult to use, fast and effective palletizing work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The principles and features of the present invention will be described below with reference to the accompanying drawings. The examples cited are only used to explain the present invention, and are not used to limit the scope of the present invention.

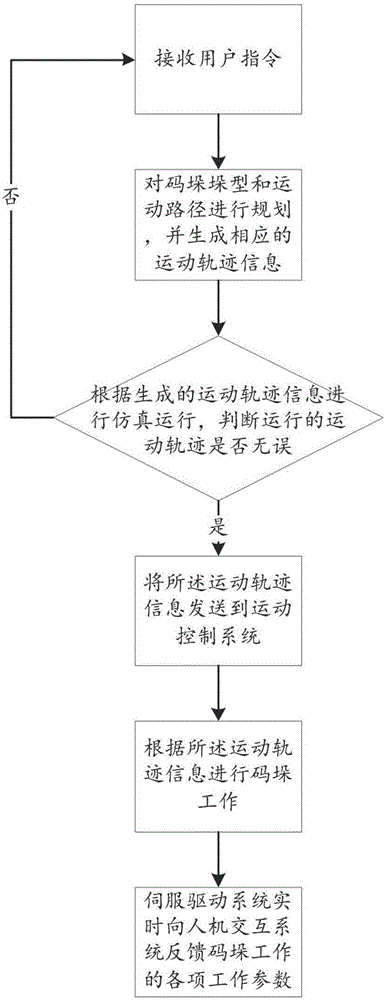

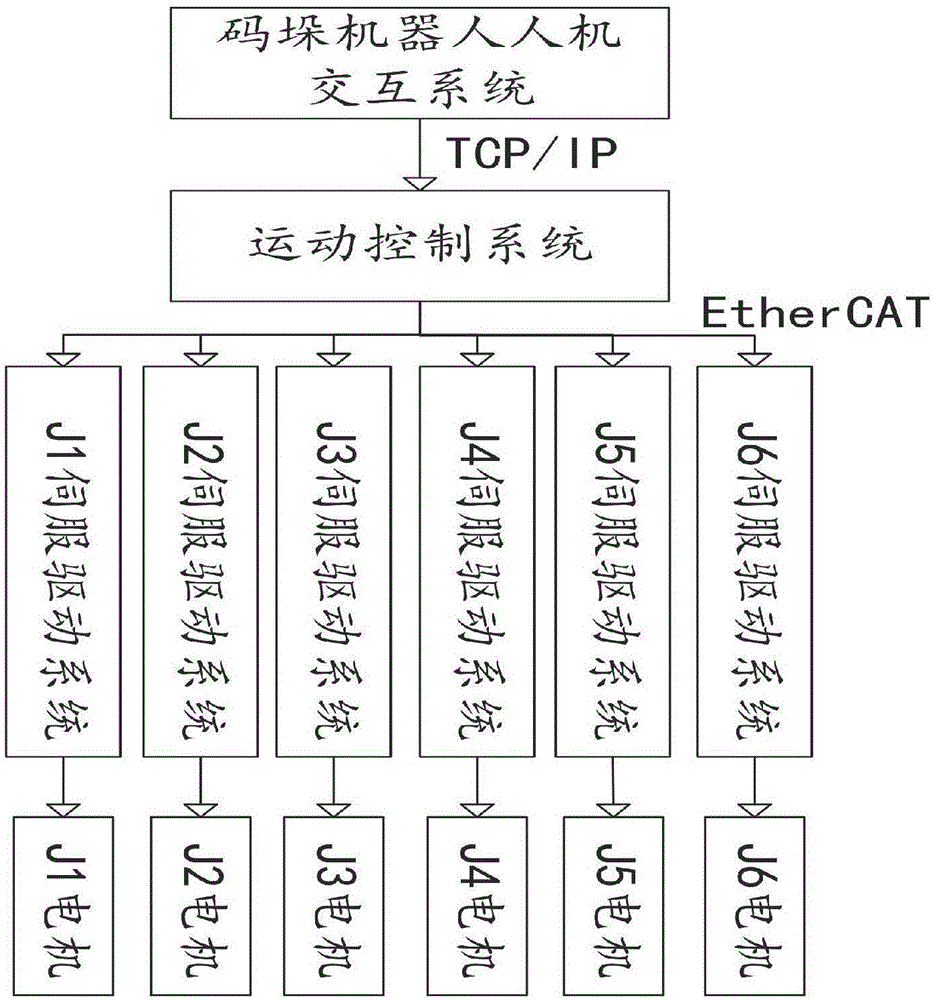

[0026] Such as figure 1 As shown, an implementation method of a palletizing robot control system includes the following steps:

[0027] Step 1. The human-computer interaction system plans the palletizing type and movement path according to the received user instructions, and generates corresponding movement track information;

[0028] Step 2. The human-computer interaction system performs simulation operation according to the generated motion trajectory information, and judges whether the running motion trajectory is correct, and if yes, sends the motion trajectory information to the motion control system, otherwise it returns to the previous step;

[0029] Step 3. The motion control system receives the motion trajectory informati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com