Multistage centrifugal compressor and air conditioning unit

A technology for centrifugal compressors and air-conditioning units, which is applied in compressors, machines/engines, refrigerators, etc., and can solve problems such as affecting the reliable operation of compressors and units, high unit manufacturing and maintenance costs, and difficulty in meeting customer requirements. , to achieve the effect of compact structure, small footprint and small axial force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

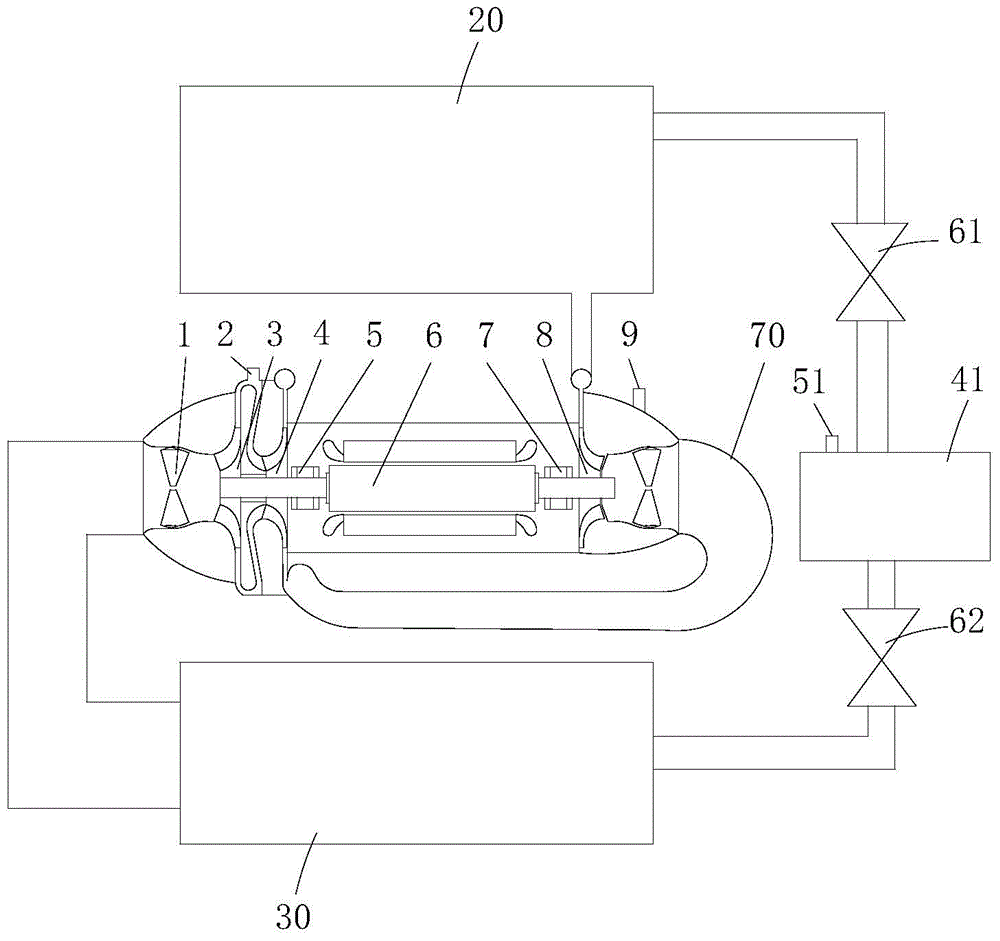

[0040] In order to solve the problem of too small pressure ratio, a multi-stage centrifugal compressor and air-conditioning unit are proposed.

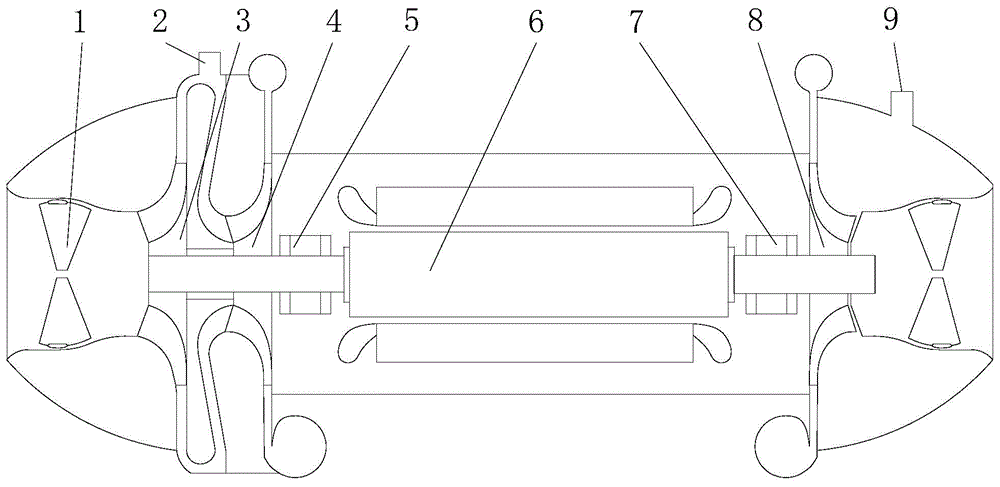

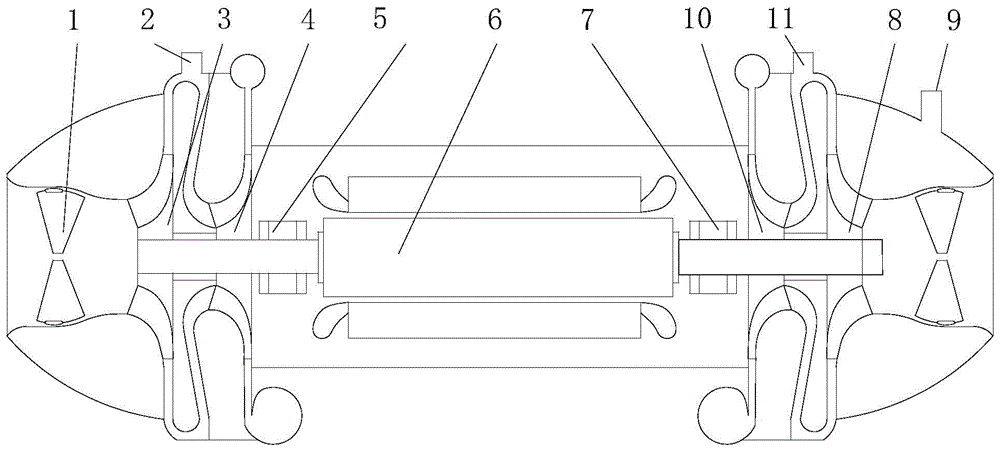

[0041] The invention provides a multi-stage centrifugal compressor, which includes a power part and an impeller part, the power part includes a motor, the motor includes a shaft, and the shaft includes a first end of the shaft and a second end of the shaft;

[0042] The impeller part includes N impellers, where N is greater than or equal to 2 and less than 10;

[0043] When N is an even number, the number of impellers on the first end of the shaft and the second end of the shaft is equal;

[0044] When N is an odd number, the number of impellers on the first end of the shaft is one more than the second end of the shaft;

[0045] The first-stage impeller is placed on the first end of the shaft, and the distance from the motor is farthest; the rest of the impellers on the first end of the shaft are arranged in ascending order;

[0046...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com